Conveying and loading device for cosmetics conveying during processing

A technology of cosmetics and conveyor racks, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor effect and low efficiency, and achieve high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

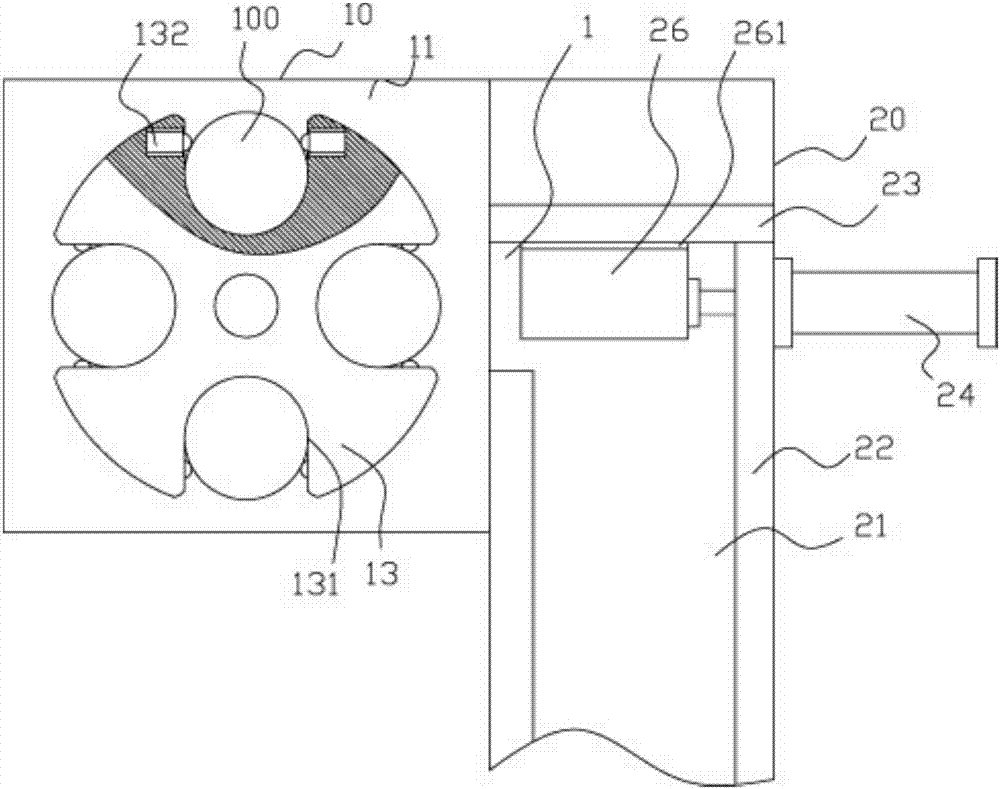

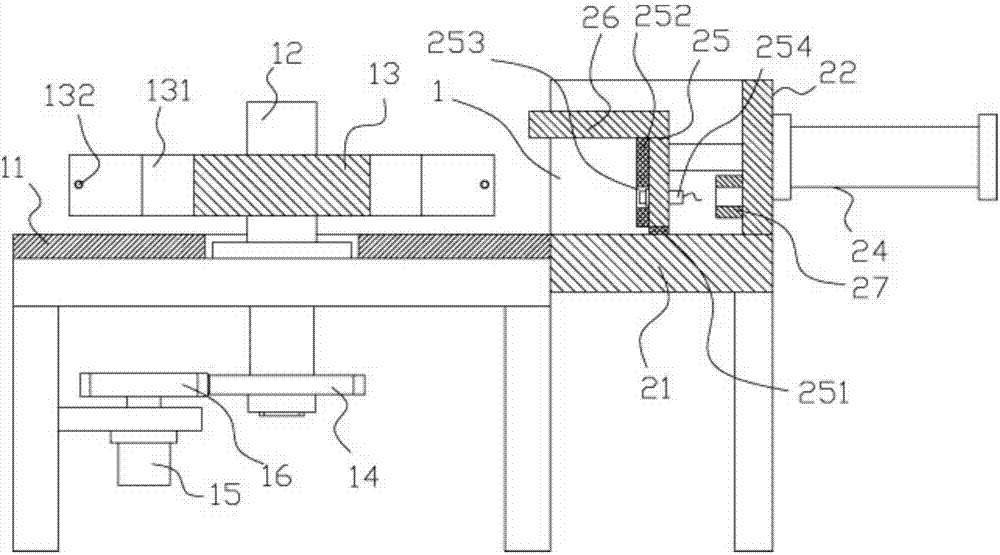

[0021] Example: see Figure 1 to Figure 2 As shown, a conveying and feeding mechanism for cosmetics processing and transportation includes a rotating frame 10 and a conveying frame 20, the right side of the rotating frame 10 is fixed with a conveying frame 20, and the top surface of the top plate of the rotating frame 10 is fixed with Self-lubricating sliding plate 11, the front left side wall of the conveying top plate 21 of conveying rack 20 is close to the right side wall of self-lubricating sliding plate 11, and the top surface of conveying top plate 21 is equal to the top surface of self-lubricating sliding plate 11, and conveying top plate 21 The left side and the right top surface of the top are fixed with a guide plate 22, the front end of the guide plate 22 on the right side of the conveying top plate 21 is fixed with a front baffle 23, and the left side of the conveying top plate 21 is connected between the guide plate 22 and the front baffle 23. A discharge port 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com