Steel tube clearing line

A steel pipe and cleaning device technology, which is applied in the direction of grinding machines, packaging, conveyor objects, etc., can solve the problems of poor working conditions, inability to realize automation, graying and rusting of steel pipes, etc., so as to save the intermediate process, facilitate grabbing and transportation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

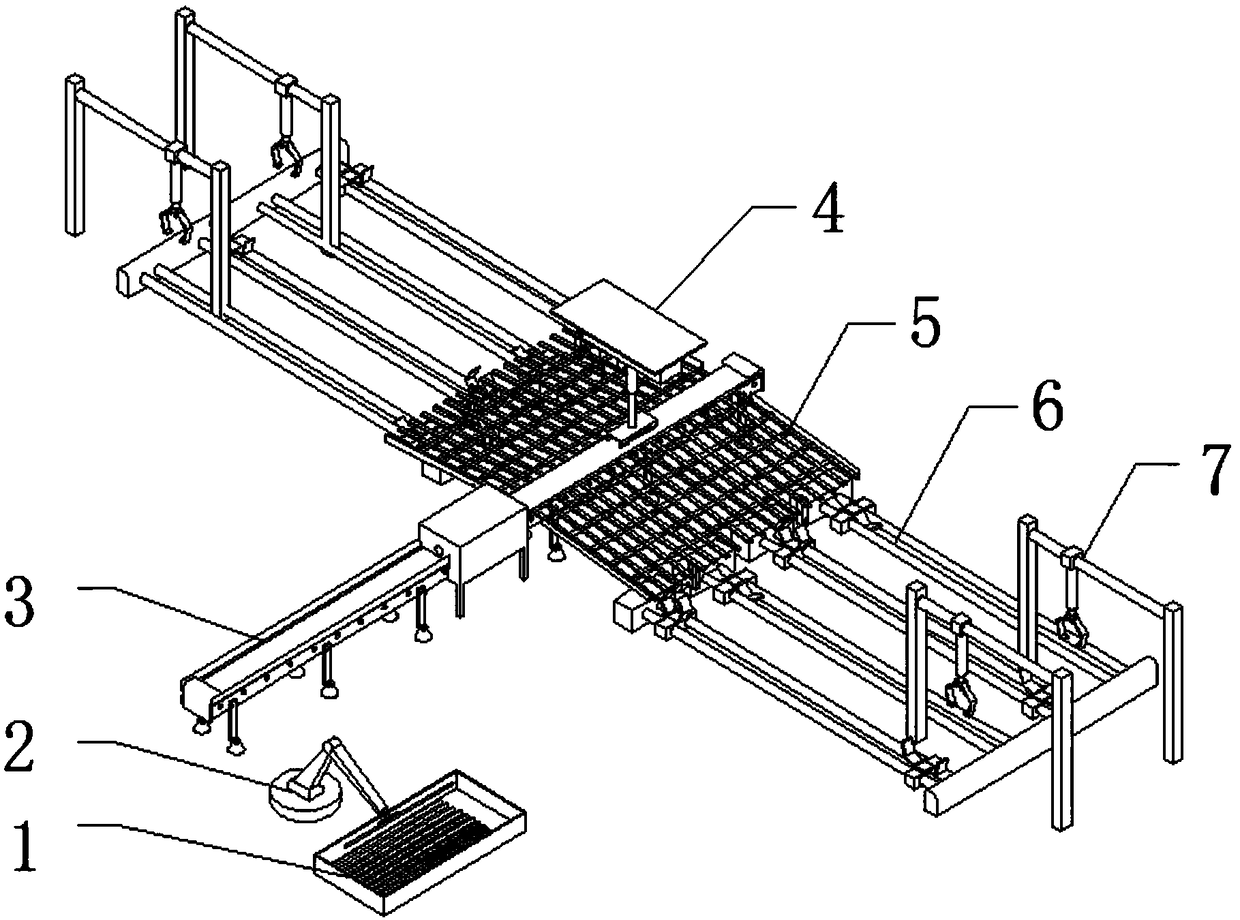

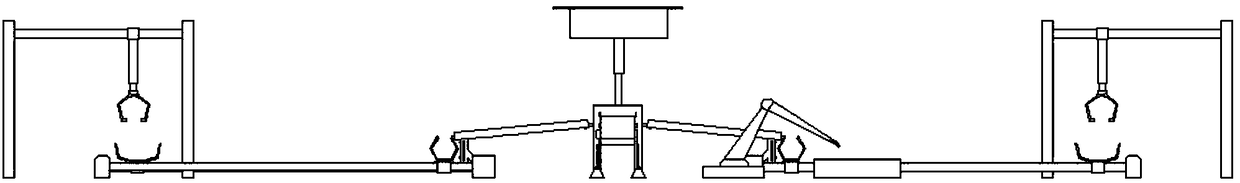

[0017] A steel pipe cleaning line is composed of a stacking device 1, a picking device 2, a cleaning device 3, a sorting device 4, a steel frame guide rail 5, a packing device 6 and a transport device 7, and the stacking device 1 is installed on the picking device 2 The cleaning device 3 is installed on the other side of the pick-up device 1, the sorting device 4 is installed above the cleaning device 3, the two sides of the cleaning device 3 are connected to the steel frame guide rail 5, and the other side of the steel frame guide rail 5 is connected to Next to the packing device 6, the transport device 7 is installed on one side of the packing device 6.

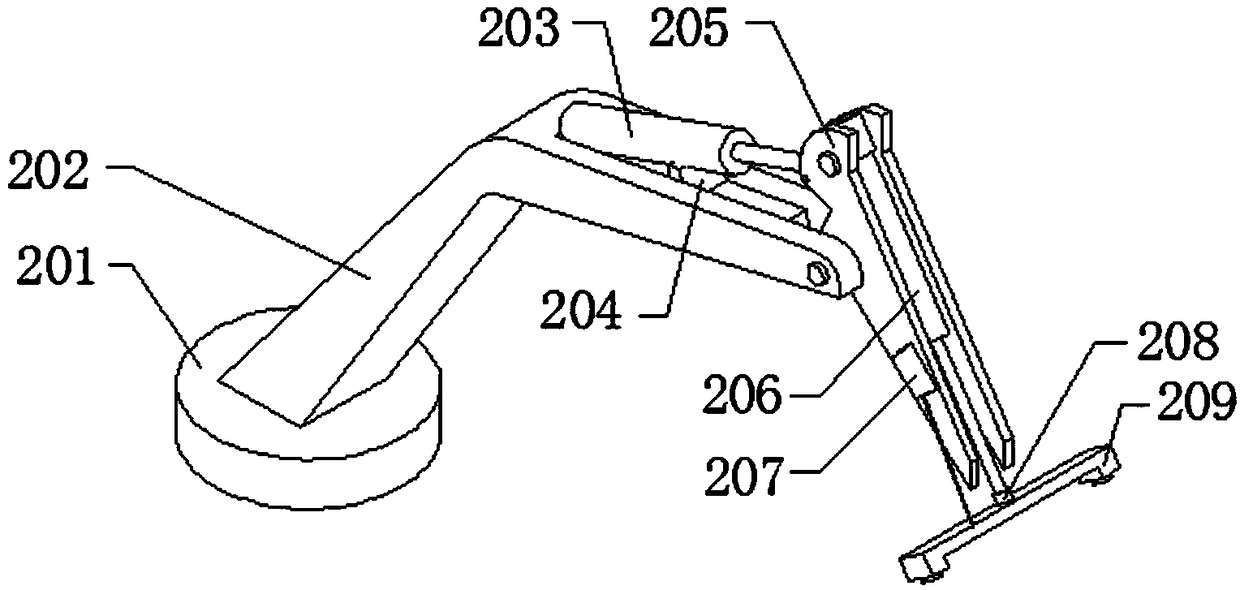

[0018] The pick-up device 2 has a structure of a turntable base 201, a support arm 202, a hydraulic cylinder 203, a hydraulic cylinder support seat 204, a cylinder support 205, a cylinder 206, a servo motor 207, a rotating device 208 and an electromagnetic gripper 209, and the support arm 202 is installed On the turntable b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com