Gripper used for vertical carrying of large-sized copper pipes

A technology for grabbing hands and copper pipes, which is applied in the direction of transportation and packaging, conveyor objects, etc., to achieve the effect of convenient grabbing, transportation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

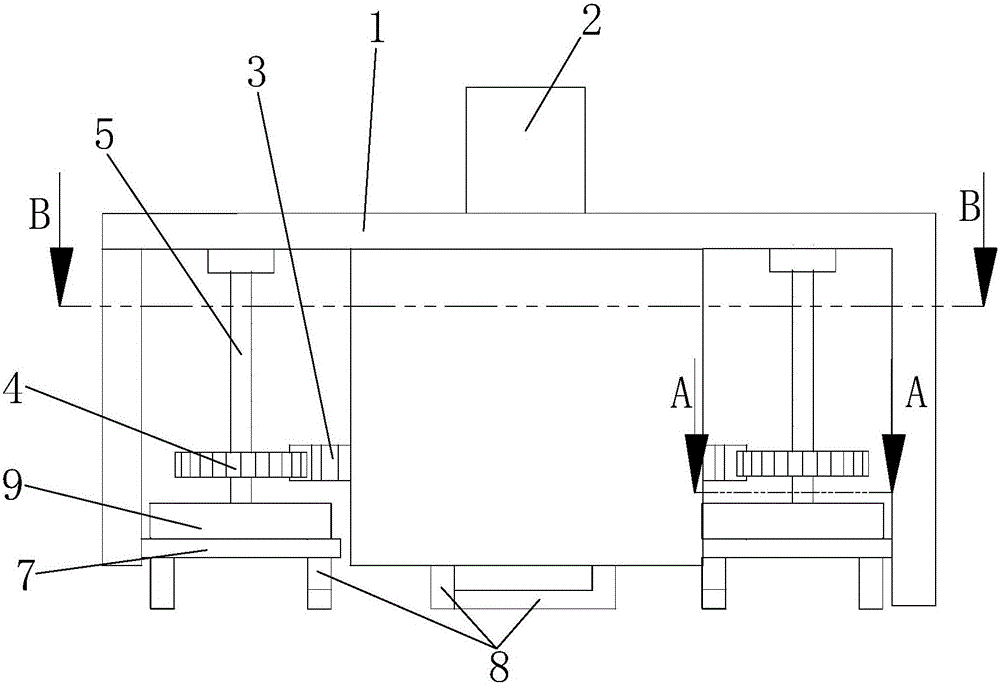

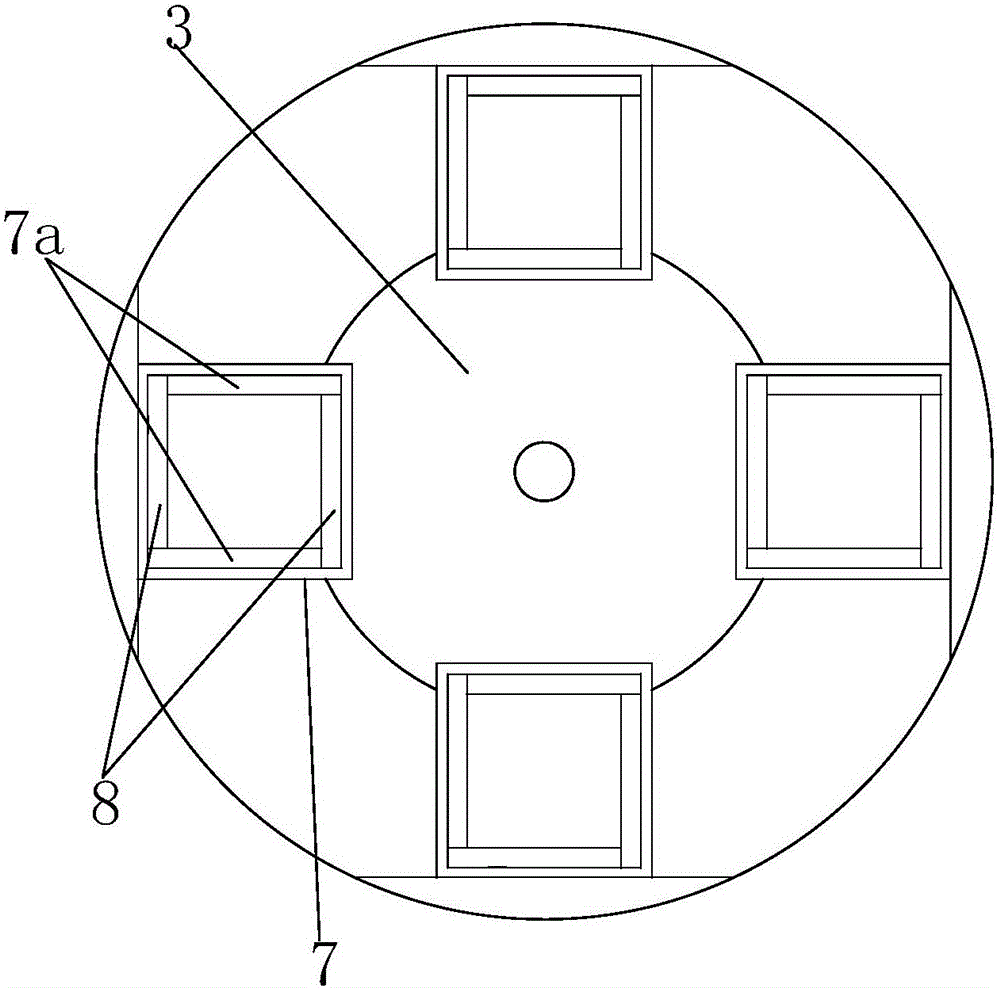

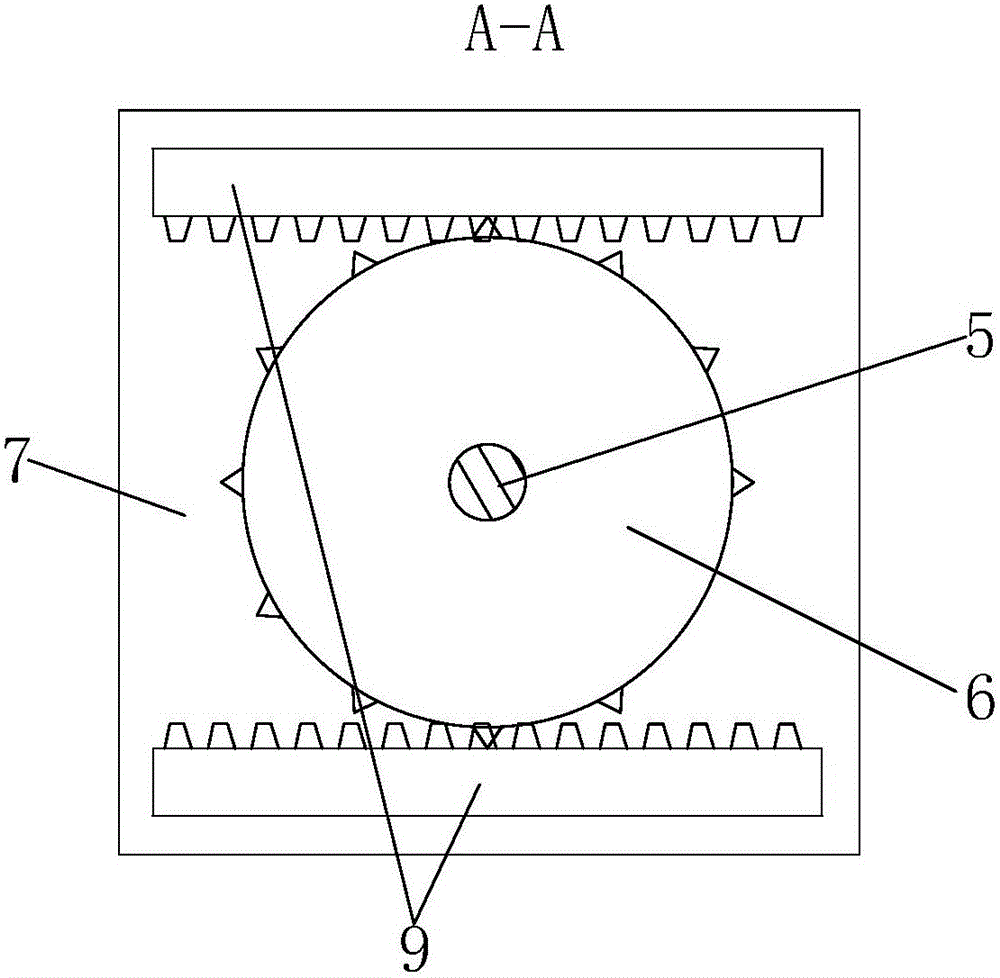

[0016] Such as Figure 1 to Figure 4 As shown, a grabbing hand for vertically transporting large copper pipes includes a main base 1, a motor 2 is installed in the center of the main base 1, and the main gear 3 is connected to the motor 2. The front of the main gear 3 , rear, left and right directions are all equipped with pinion gears 4 meshed with the main gear 3, the pinion gears 4 are connected with a countershaft 5, and the lower part of the countershaft 5 is connected with a transmission gear 6.

[0017] The lower end of the main base 1 is fixedly connected with four hanger brackets 7, and the hanger brackets 7 are provided with two parallel chute 7a, and L clips 8 are slidably installed in the chute 7a. The upper ends of the clamping blocks 8 are welded with toothed racks 9 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com