Bilateral adsorption composite feeding system and production method thereof

A technology of a feeding system and a production method, which is applied in the field of auto parts manufacturing devices, can solve problems such as inaccurate placement and positioning, affect product quality, and high labor intensity, and achieve product quality assurance, product quality assurance, and labor intensity reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

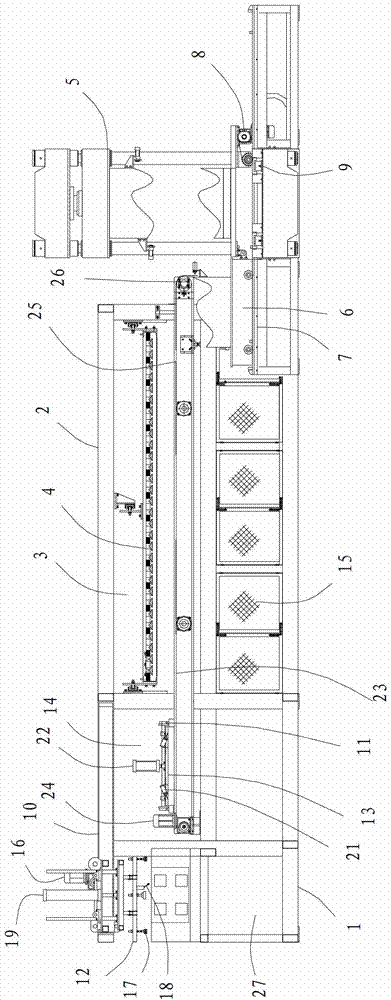

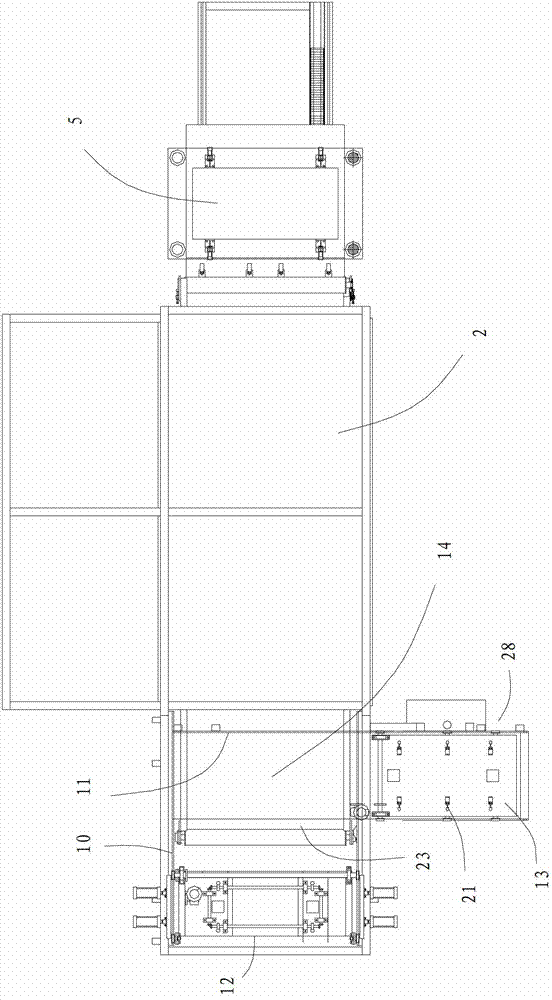

[0018] refer to Figure 1-2 , a double-sided adsorption synthesis feeding system, which is arranged in front of the mobile mold table 6 of the pressing machine 5, including a frame 1 and an oven 2, and a tunnel heating zone 3 and a heating element 4 are arranged in the oven 2, and the pressing machine 5 includes The moving mold table 6 moving on the moving mold rail 7 is driven by the mold moving motor 8, and a lifting cylinder 9 is provided on the mold moving guide rail 7 for lifting the mold on the moving mold table 6 for pressing. Pressing machine 5 is positioned at one end of frame 1, is respectively provided with the first feeding area 27 and the second feeding area 28 on the two sides of the other end of frame 1, and frame 1 is provided with to the first feeding area. The first feeding track 10 that district 27 extends is provided with the second feeding track 11 extending to the second feeding area 28 on the frame 1 below the first feeding track 10, and the second feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com