Chemical raw material bag carrier

A technology of raw material bags and trucks, applied in the direction of transportation and packaging, conveyor objects, support frames, etc., can solve the problems of increasing manual labor and troubles, and achieve the effect of reducing manual labor and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

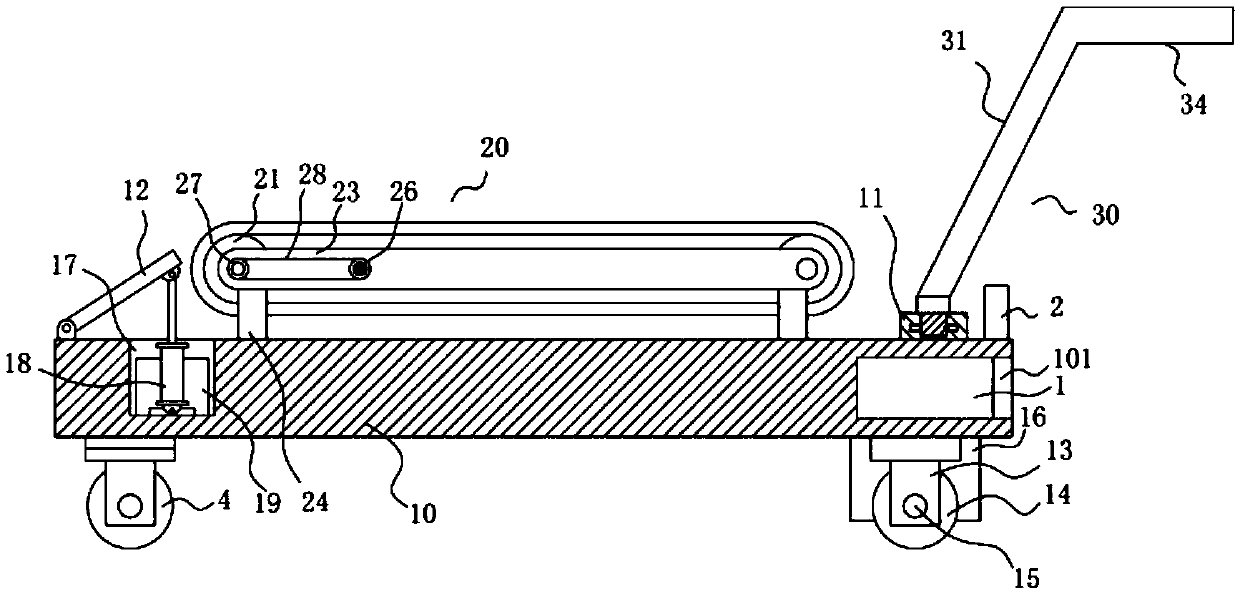

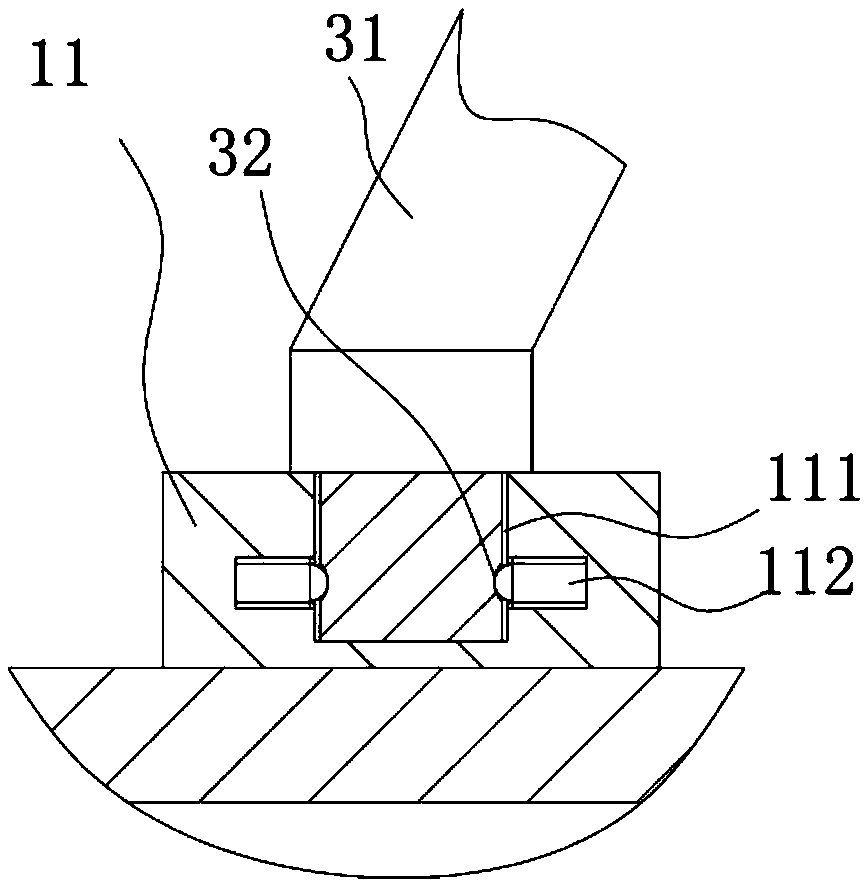

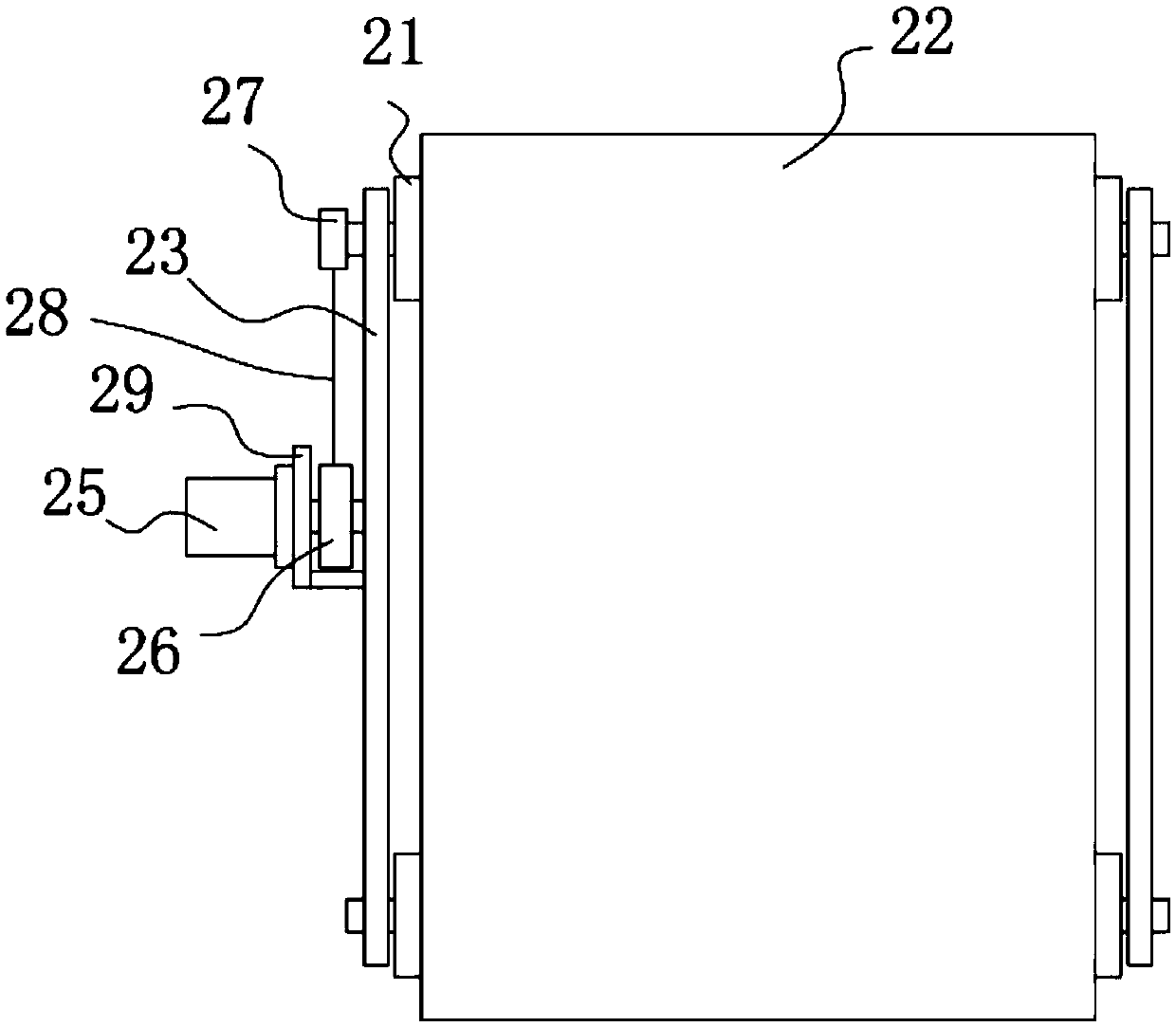

[0019] Example: see Figure 1 to Figure 4 As shown, a chemical material bag transport vehicle includes a frame body 10, the top surface of the frame body 10 is fixed with an upper conveying frame 20, the right end of the frame body 10 is fixed with a connecting seat 11, and the connecting seat 11 is fixed There is a handle 30, the left end of the frame body 10 is provided with a lifting plate 12, two vertical plates 13 are fixed on both sides of the right end of the bottom surface of the frame body 10, and the wheels 14 are hinged to the corresponding two through the connecting shaft 15 On two vertical plates 13, the two sides of the left end of the bottom surface of the frame body 10 are fixed with universal wheels 4, and the middle of the bottom surface of the right side of the frame body 10 is fixed with a double output shaft drive motor 16 and a double output shaft drive motor 16 The two output shafts are connected to the connecting shaft 15 fixed on the corresponding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com