Waste plastic recycling equipment

A waste plastic recycling technology, applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of bubbles and cracks in plastic products, achieve full contact, high efficiency, and reduce water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

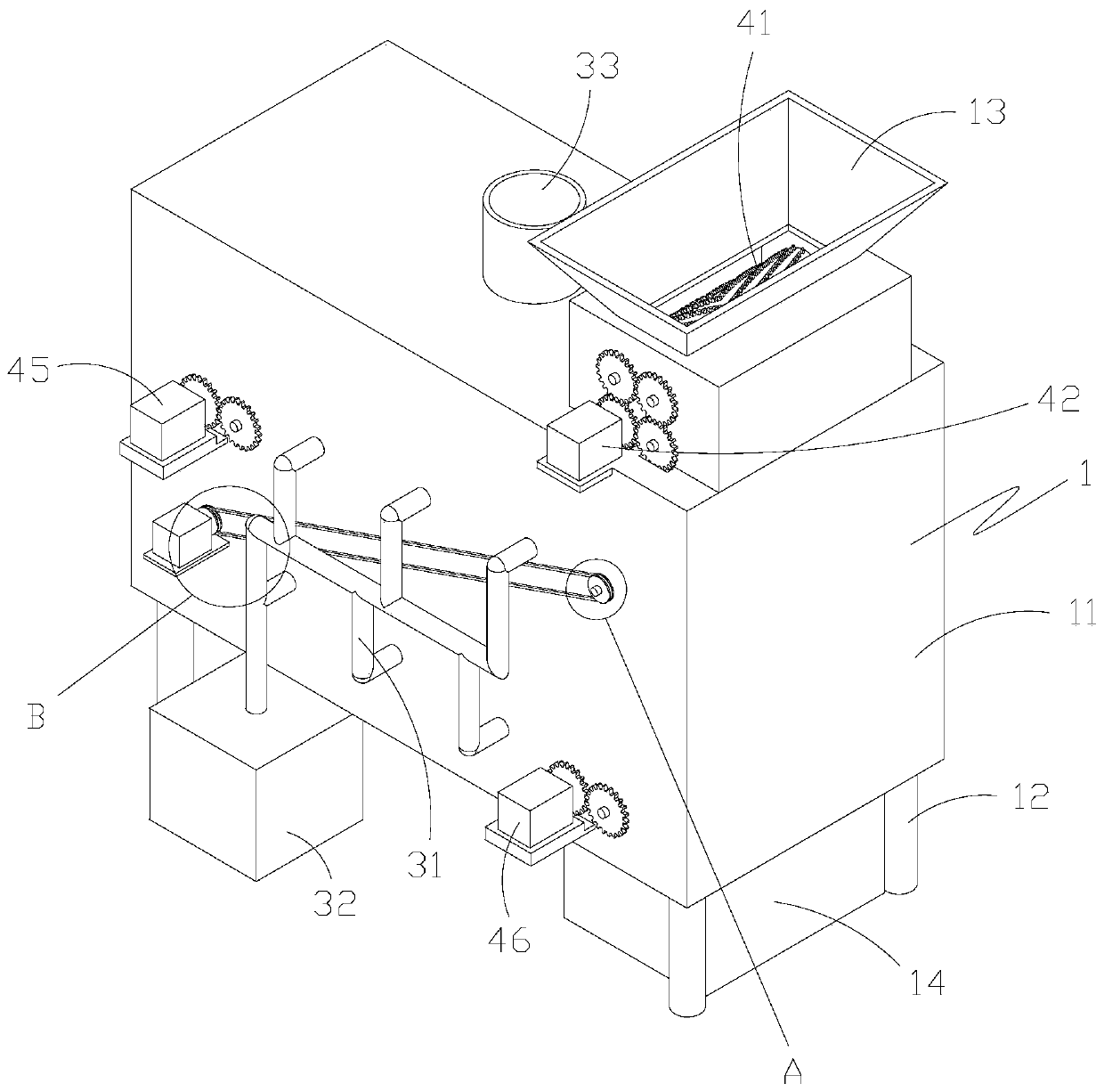

[0026] like Figure 1-8 As shown, a waste plastic recycling equipment includes a casing 1, a drying device and a crushing device; the casing 1 includes a casing 11, a support column 12, a feed hopper 13 and a collecting hopper 14; the support column is welded to the casing On the lower surface of the shell, it plays the role of supporting and fixing the shell; on the upper surface of the shell, a feeding hopper is installed to facilitate adding raw materials into the shell; a collecting hopper is placed under the shell, so that from the shell The finished material discharged from the discharge port can be collected by the collecting hopper, which is convenient for subsequent processing.

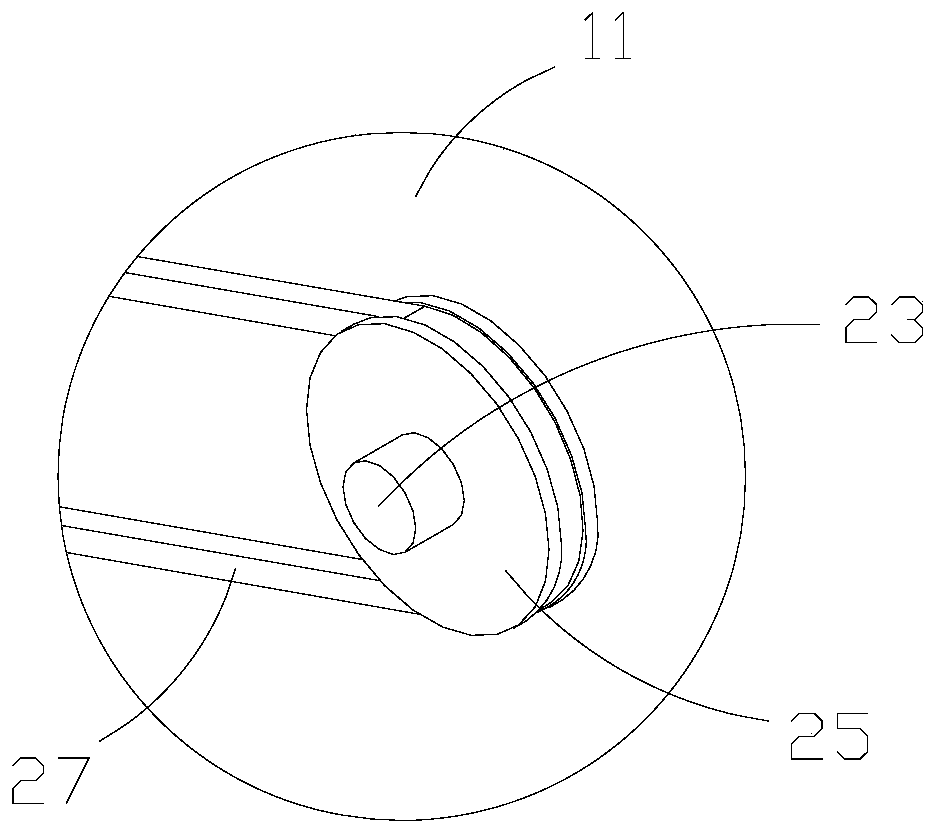

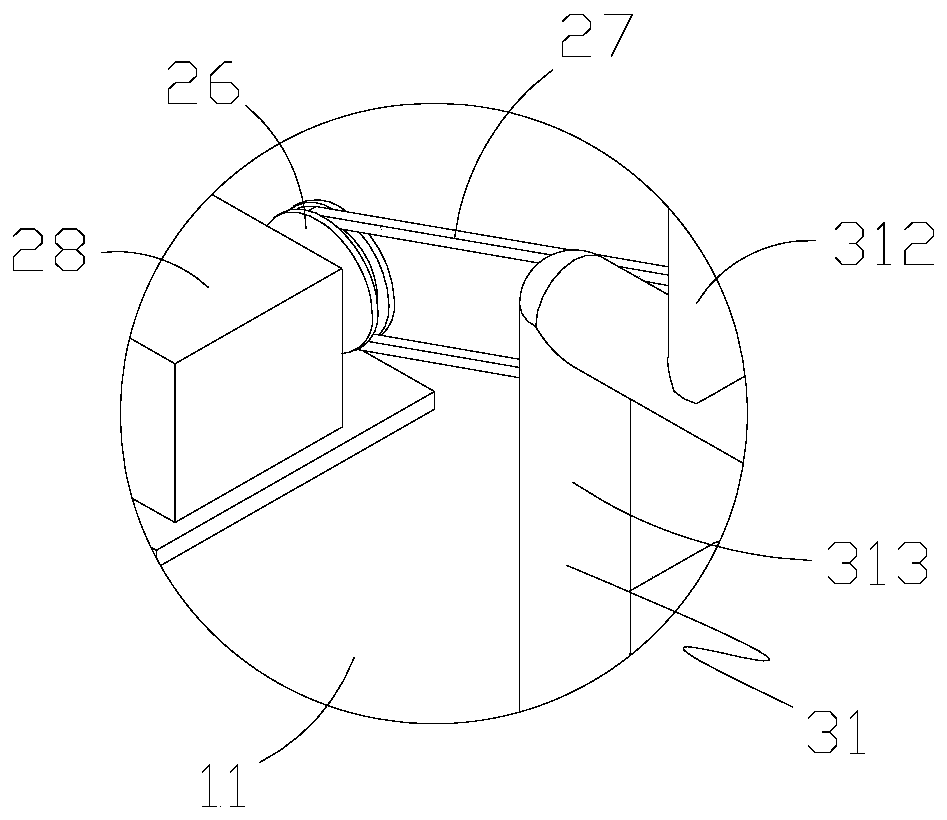

[0027] Specifically, the drying device includes an air outlet structure, a vibrating structure and a vibrating driving structure; wherein the vibrating structure includes an upper vibrating plate 20, a lower vibrating plate 21 and a material blocking plate 22; both the upper vibrating plate a...

Embodiment 2

[0034] like Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 is that the crushing device is optimized. The crushing device includes a primary crushing roller set, a first power member 42, a primary transmission structure and a secondary crushing structure. The primary crushing roller set is installed in the Inside the hopper 13, it includes a first roller 411, a second roller 412, a third roller 413 and a fourth roller 414; wherein the first roller 411 includes a roller shaft 4111, a front crushing belt 4112 and a rear crushing belt 4113, the two ends of the roller shaft are respectively connected with the inner wall bearing of the feeding hopper, so that the first roller can rotate back and forth relative to the feeding hopper; the front crushing belt and the rear crushing belt are installed on the outer surface of the roller shaft, It is distributed in a spiral structure, and multiple front crushing zones and rear crushing zones are uniformly op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com