Patents

Literature

80results about How to "Less prone to noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

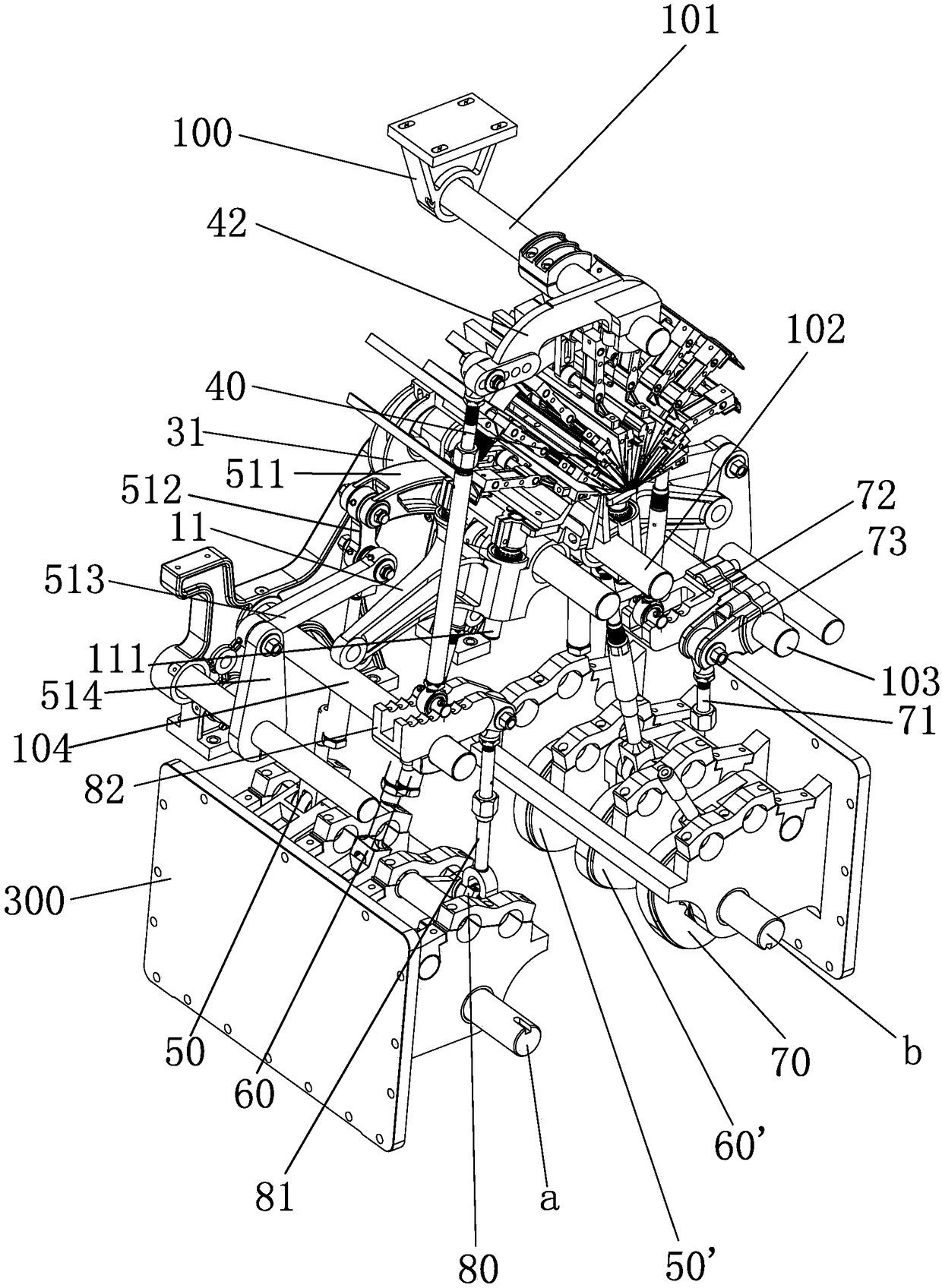

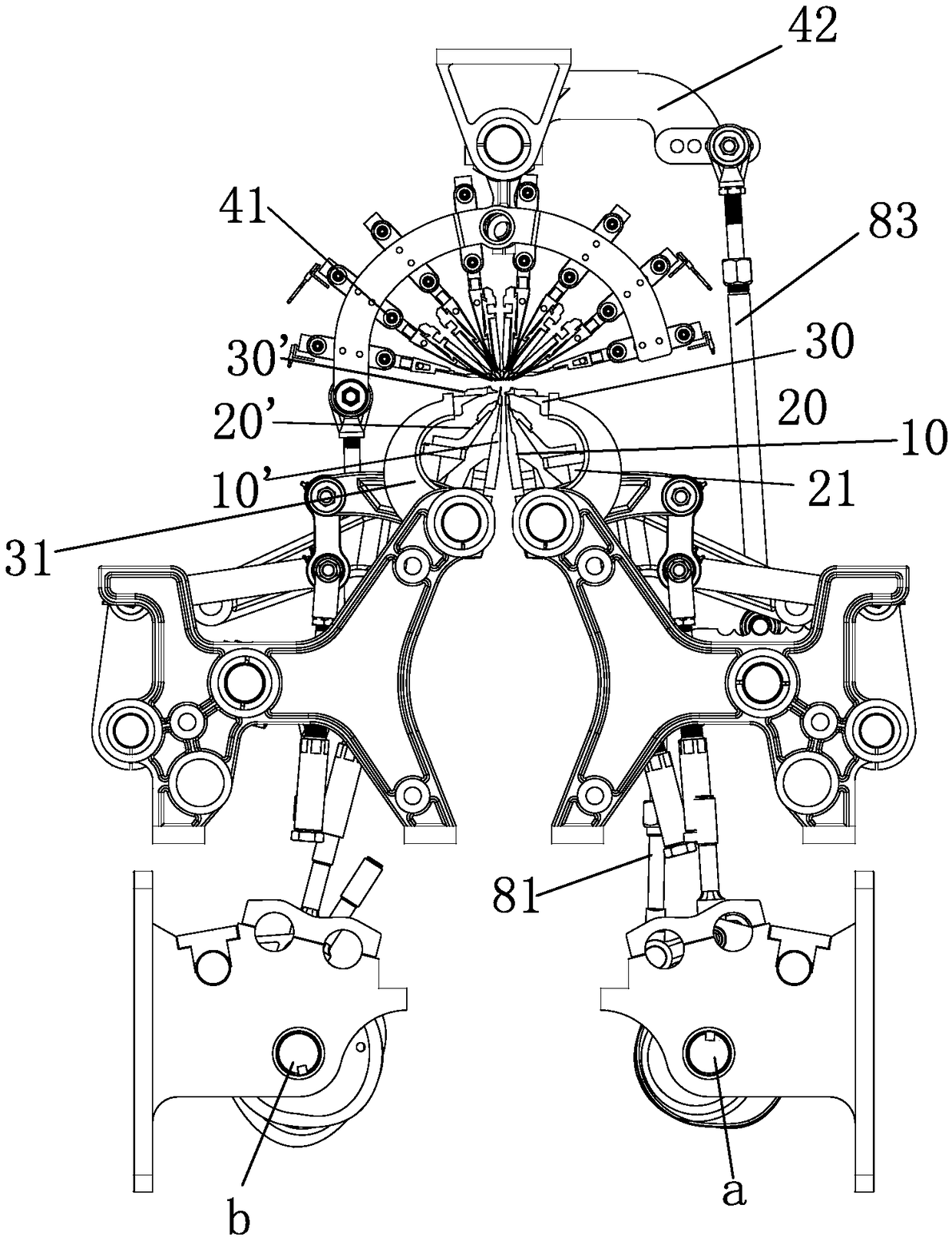

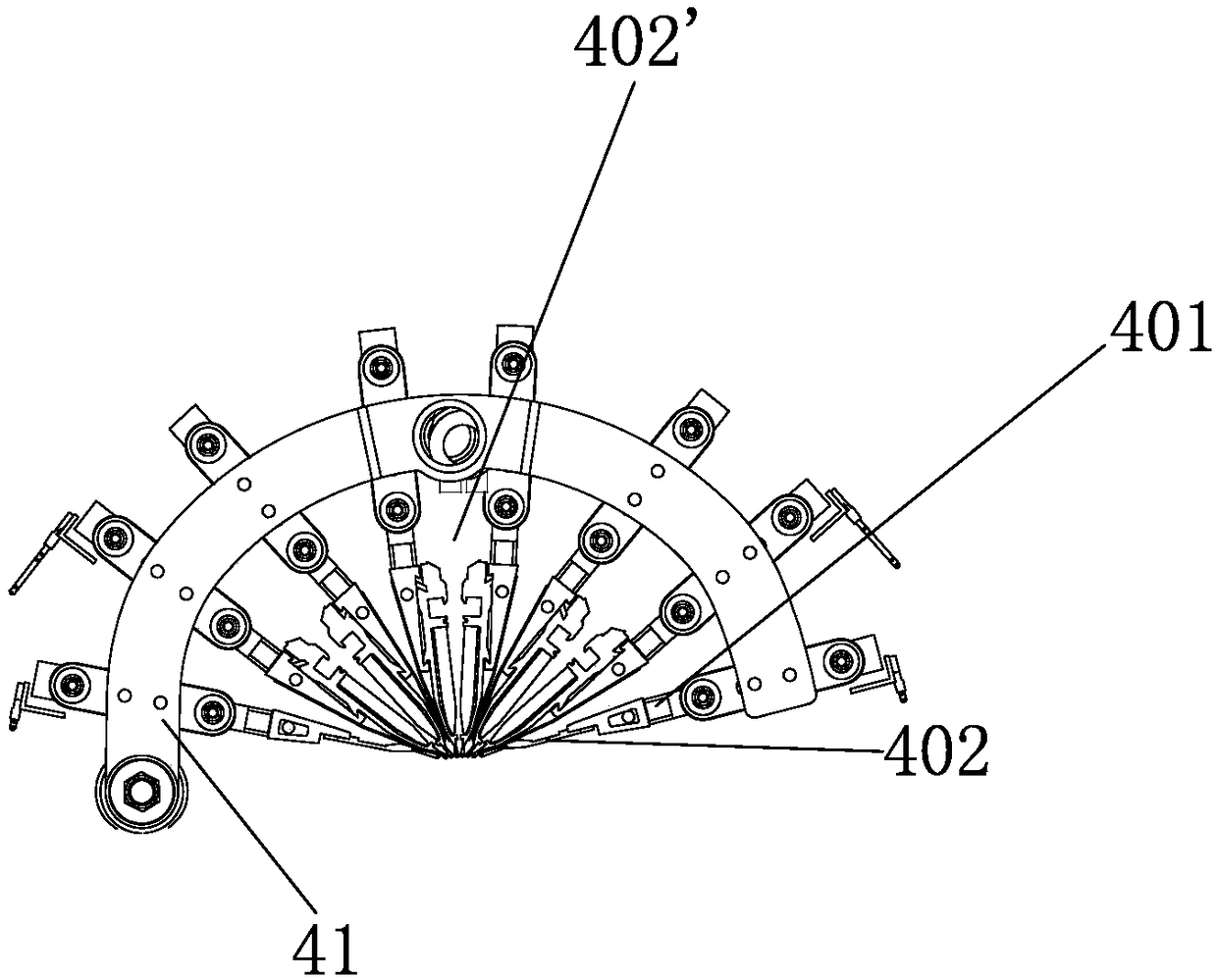

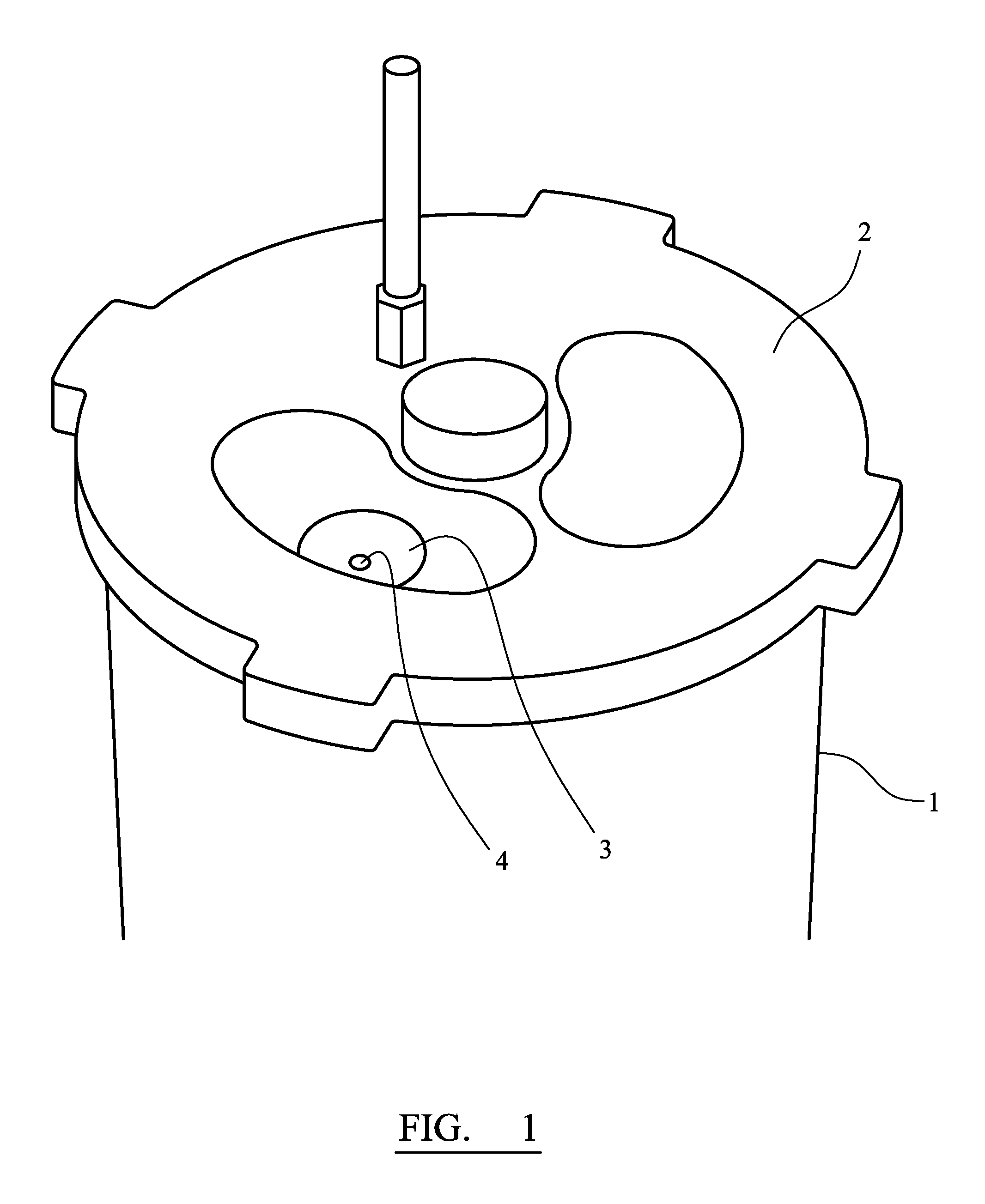

Three-jacquard warp-knitting machine

The invention relates to the field of knitting machinery, in particular to a three-jacquard warp-knitting machine. The three-jacquard warp-knitting machine comprises a rack, a loop formation device, aguide bar device and a transmission device, wherein the loop formation device, and the guide bar device and the transmission device are arranged on the rack; the guide bar device comprises a guide bar bed assembly and a guide bar seat fixedly connected with the guide bar bed assembly; the upper end of the guide bar bed assembly is in suspended connection with a first pendulum shaft of the rack, and the first pendulum shaft is fixedly connected with an upper swing arm assembly; the guide bar bed assembly is composed of eight guide bar beds, each guide bar bed is arranged on the guide bar seat,each guide needle is arranged on the corresponding guide bar bed, the guide bar beds located at the two sides are both provided with the guide needles, and the six guide bar beds located in the middle are respectively provided with three sets of piezoelectric ceramic jacquard needles. The invention provides the three-jacquard warp-knitting machine which has the advantages that colors are abundantand products satisfy market requirements.

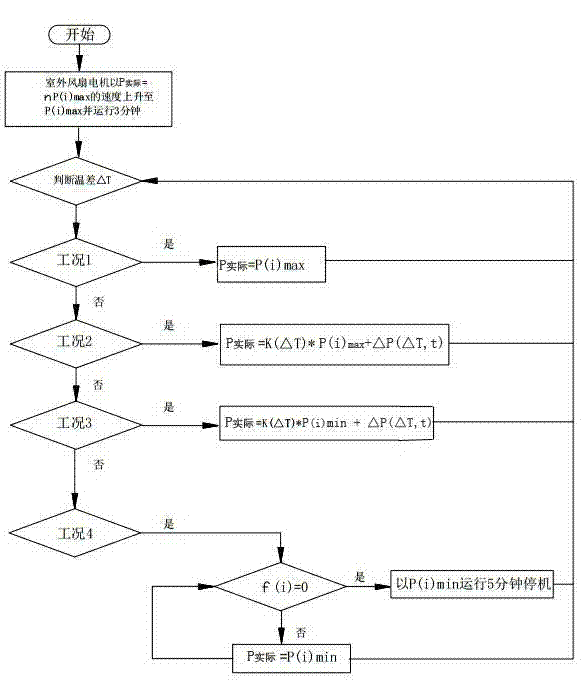

Air-conditioner outdoor motor control method

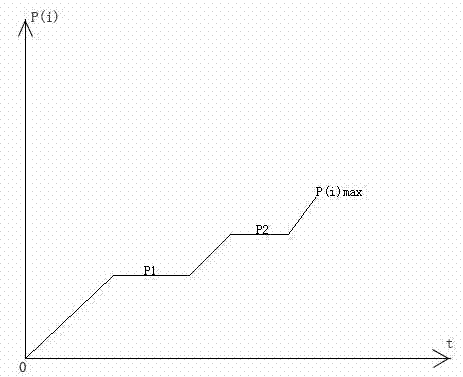

InactiveCN103115416ASteady increase in speedImprove use comfort performanceSpace heating and ventilation safety systemsLighting and heating apparatusMotor controlStart up

The invention relates to the technical field of air-conditioners in electrical equipment, in particular to an air-conditioner outdoor motor control method, and aims at reducing noise and vibration production in the process of starting to a high rotation speed of an overall unit. The air-conditioner outdoor motor control method includes the following steps: S1, starting up: the rotation speed of an outdoor fan motor is improved to P (i) max from an actual rotation speed P (actual), and then the outdoor fan motor operates for 3minutes, wherein the P (actual) is equal to n P (i) max; and S2, the difference value delta T between temperature of indoor environment and set temperature of an indoor unit is judged. According to the air-conditioner outdoor motor control method, the rotation speed of the starting stage of the outdoor motor is set to be from low to high, and therefore the noise and the vibration are not easily produced in the process of the starting to the high rotation speed of the overall unit, and use comfortable sensation of users is improved.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

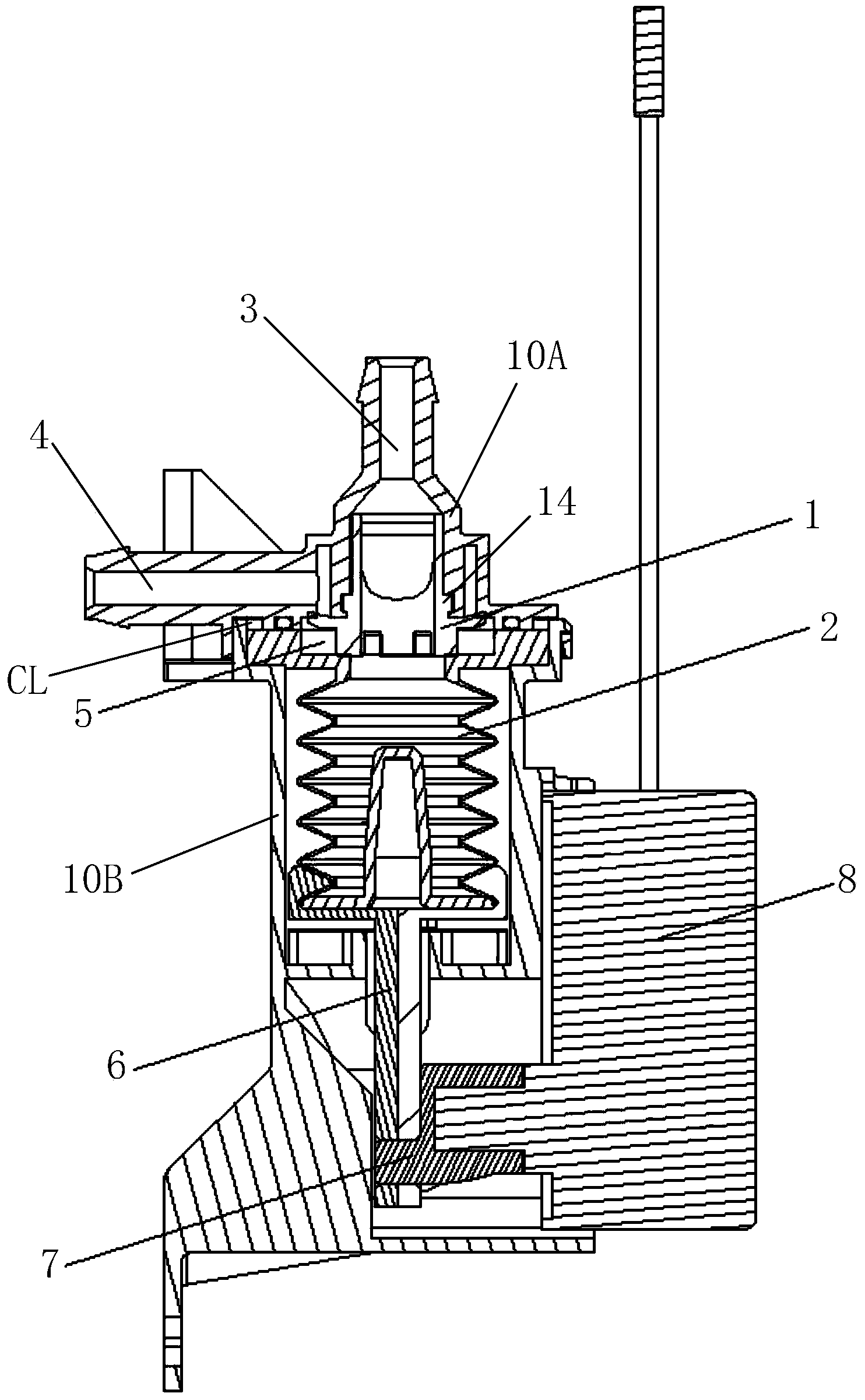

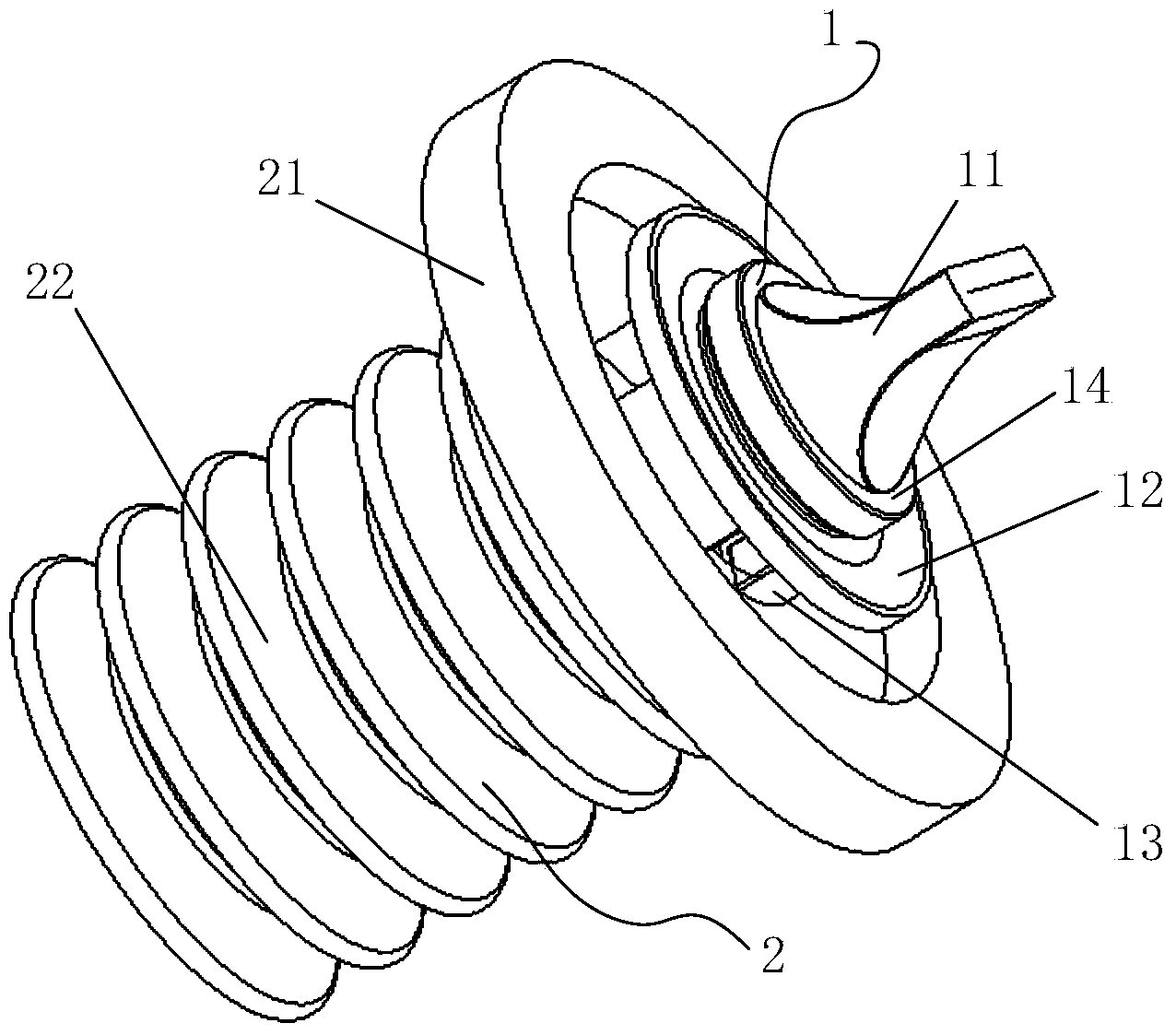

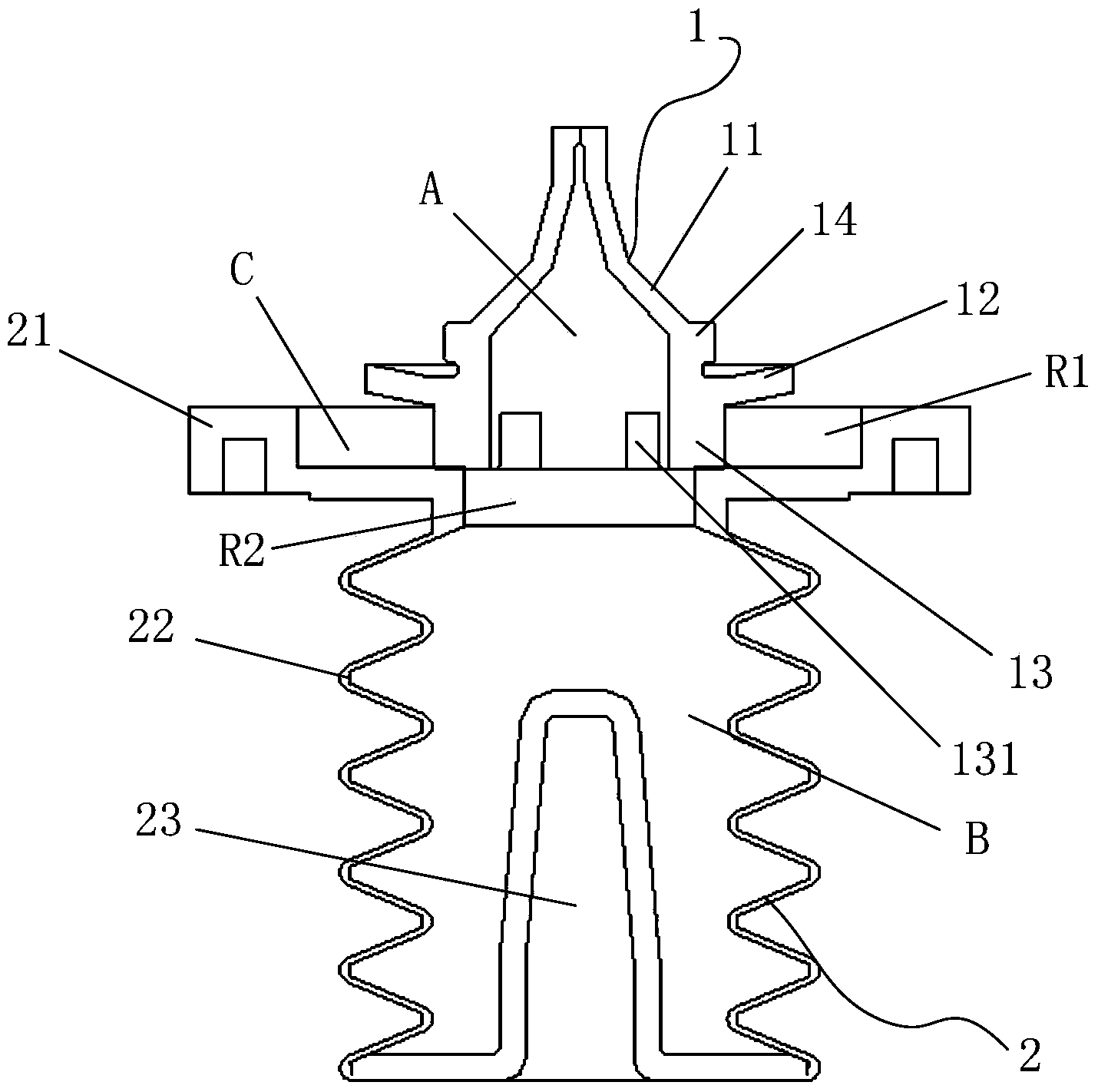

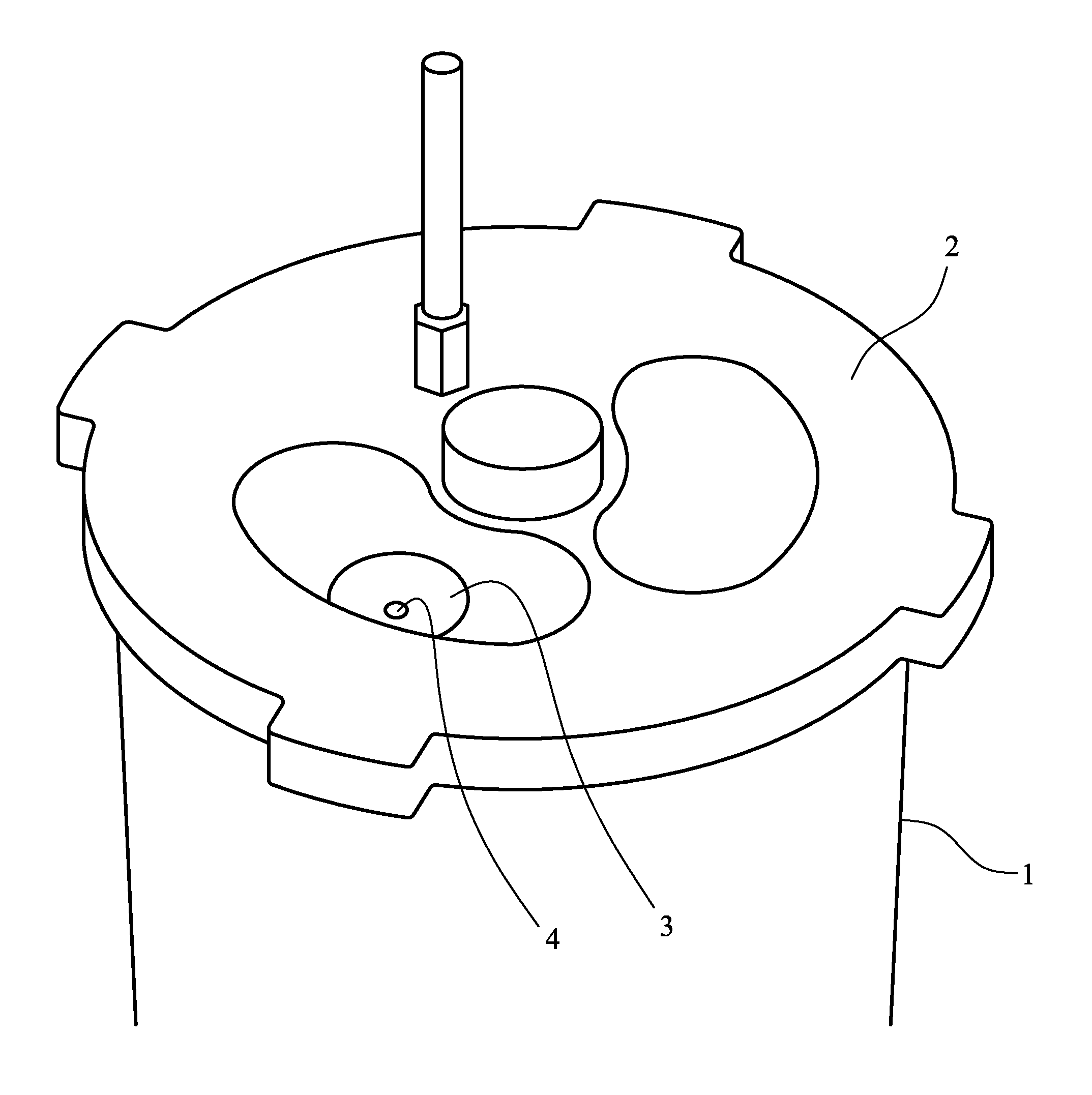

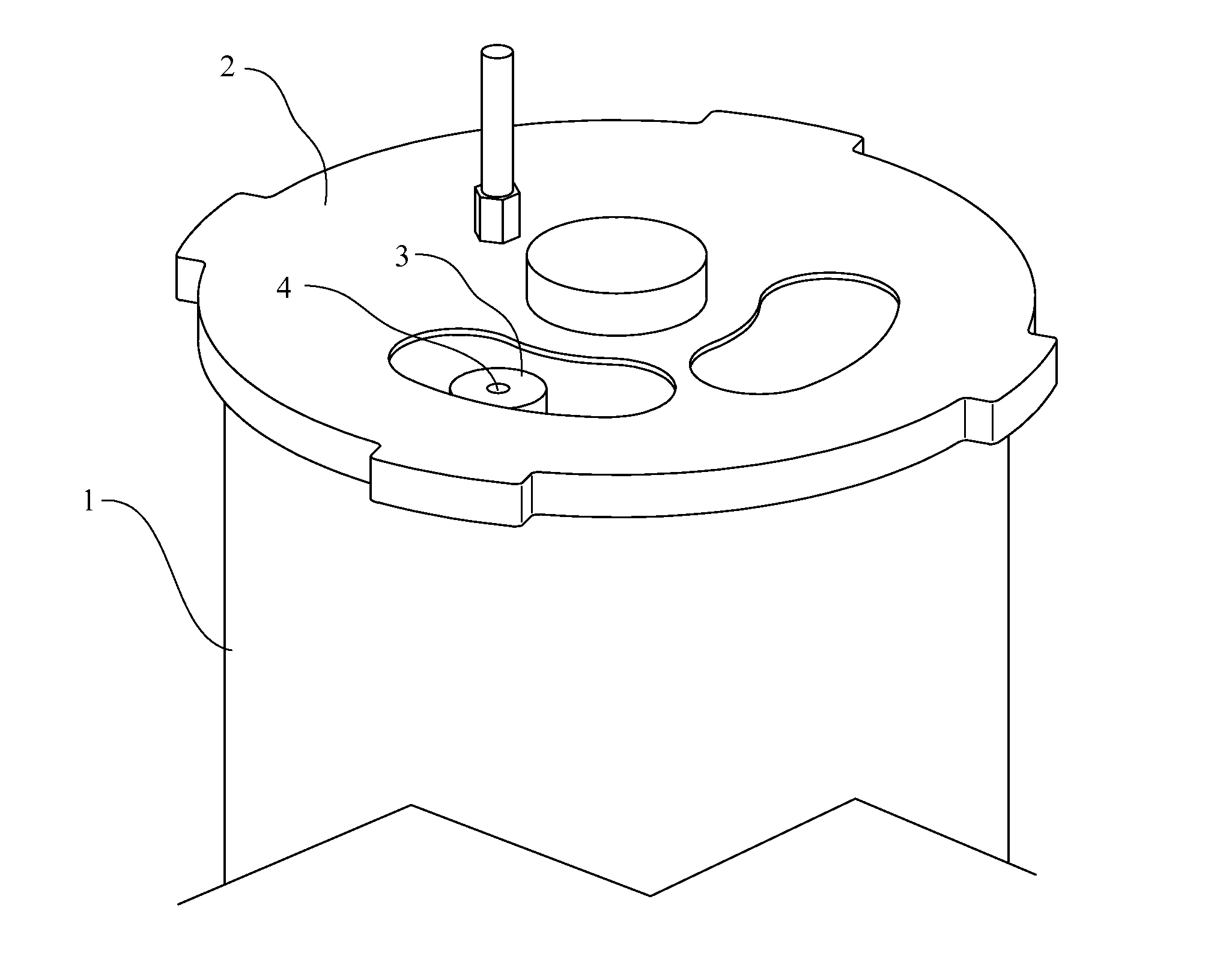

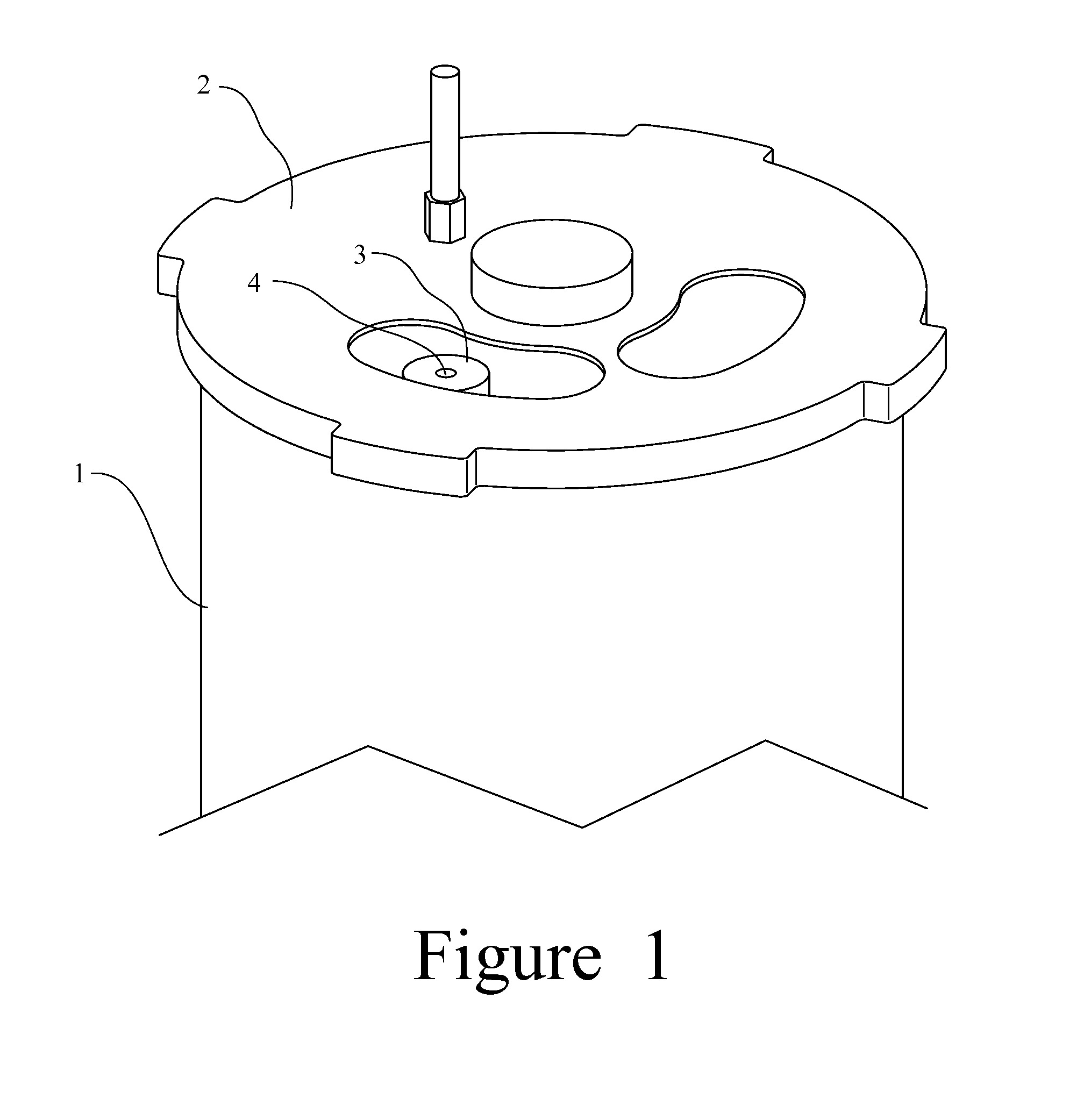

Feeding valve mechanism and valve pump using same

ActiveCN103758747AOptimized installation spaceEliminate friction membersPositive displacement pump componentsPump controlEngineeringMechanical engineering

Owner:JIANGSU LEILI MOTOR

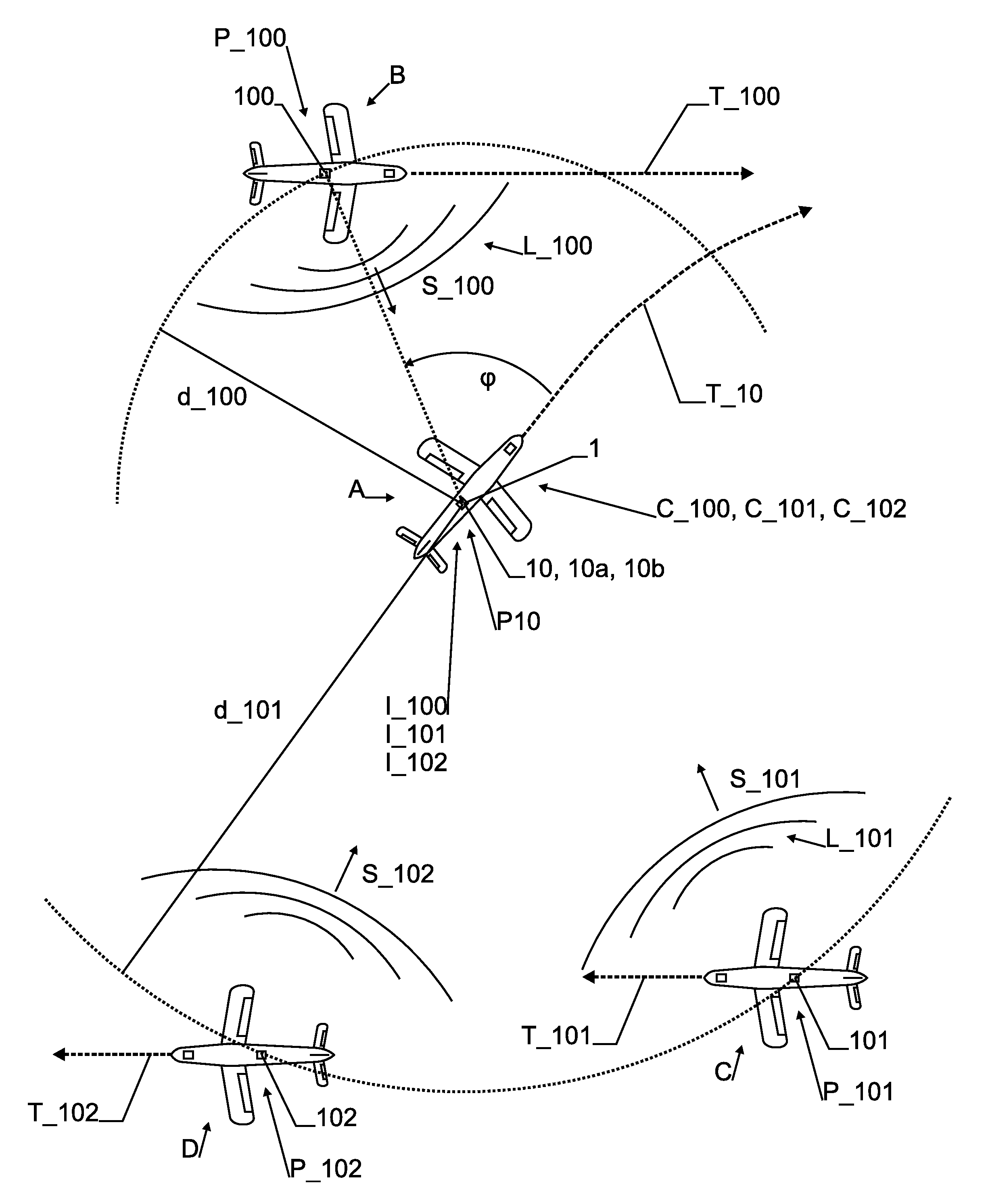

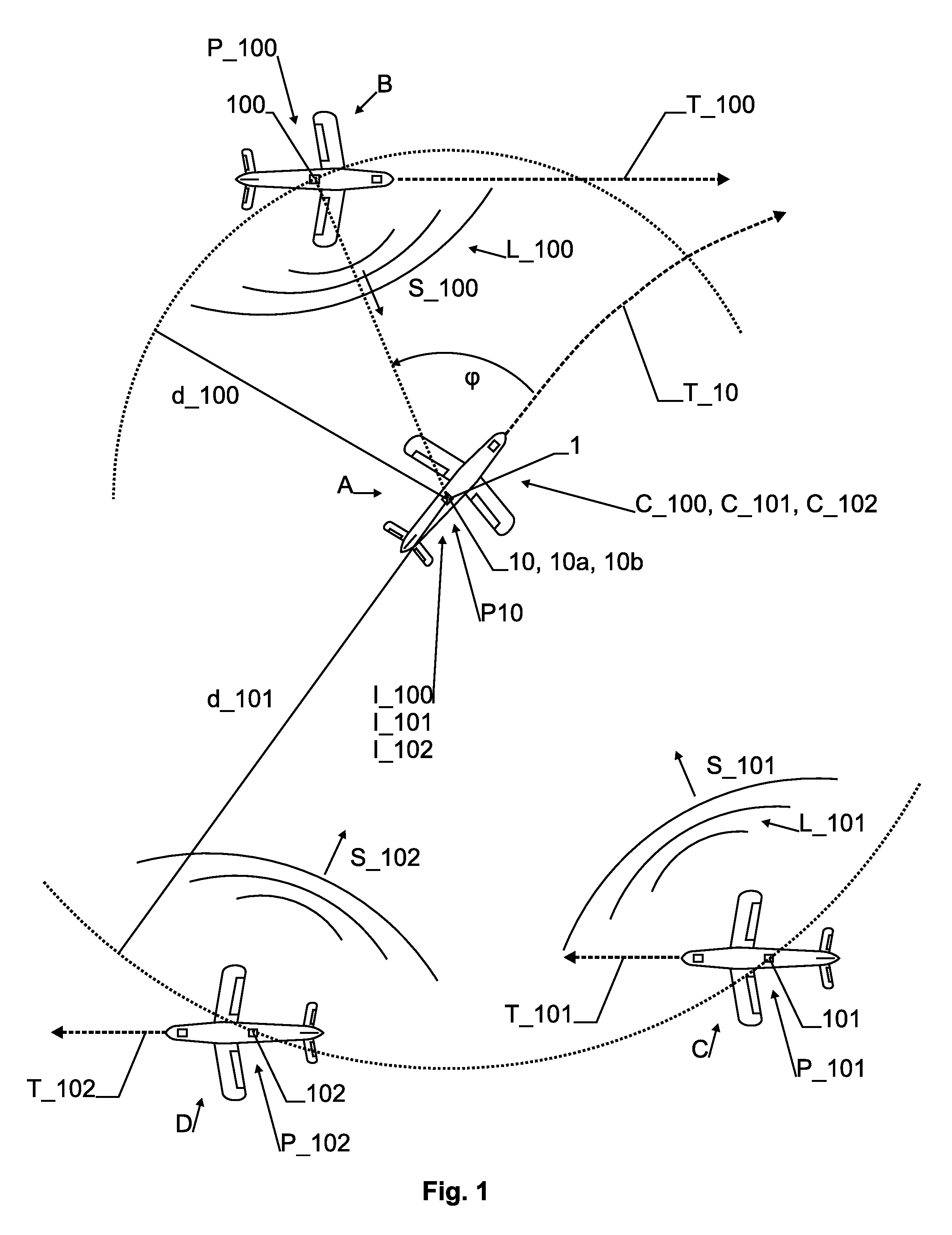

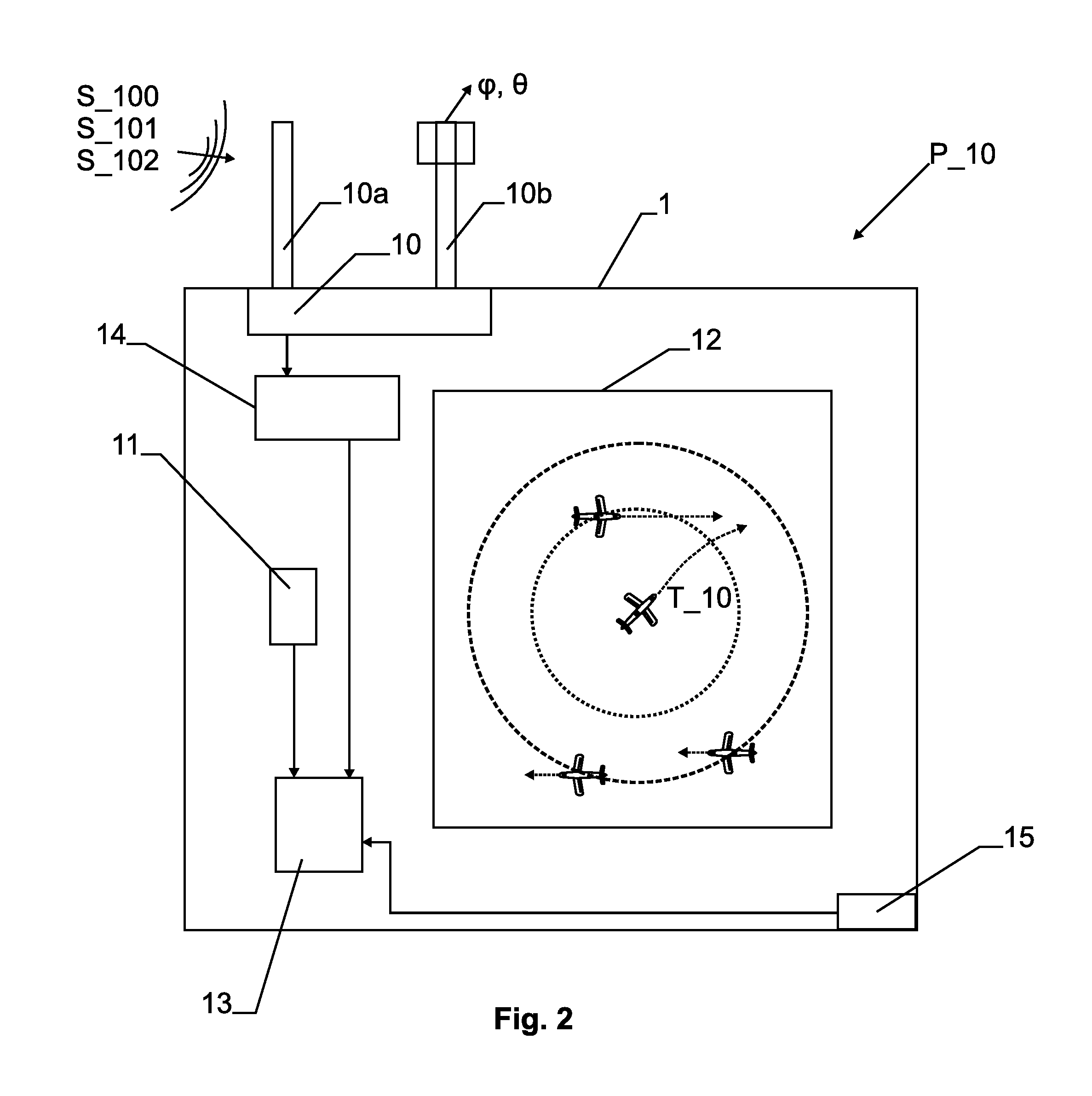

Method and device for estimating a distance

InactiveUS20150247914A1Improve reliabilityLess-prone to noiseAnti-collision systemsPosition fixationEngineeringImproved method

An improved method for avoiding mid-air collision in aviation is disclosed. The method relies on a calibration of radio signal intensities I with radio signal encoded position information L. In other words, after a first reception of a radio signal S advantageously comprising remote aircraft position information L, the radio signal intensity I is measured and a correction factor C is derived. During a next encounter of the radio signal S, a second distance estimation d can be derived using the signal intensity I and the correction factor C. Preferably, relative positioning data is acquired together with the correction factor C and a plurality of correction factors for different relative positions is combined in an at least partly continuous correction function.

Owner:FLARM TECH

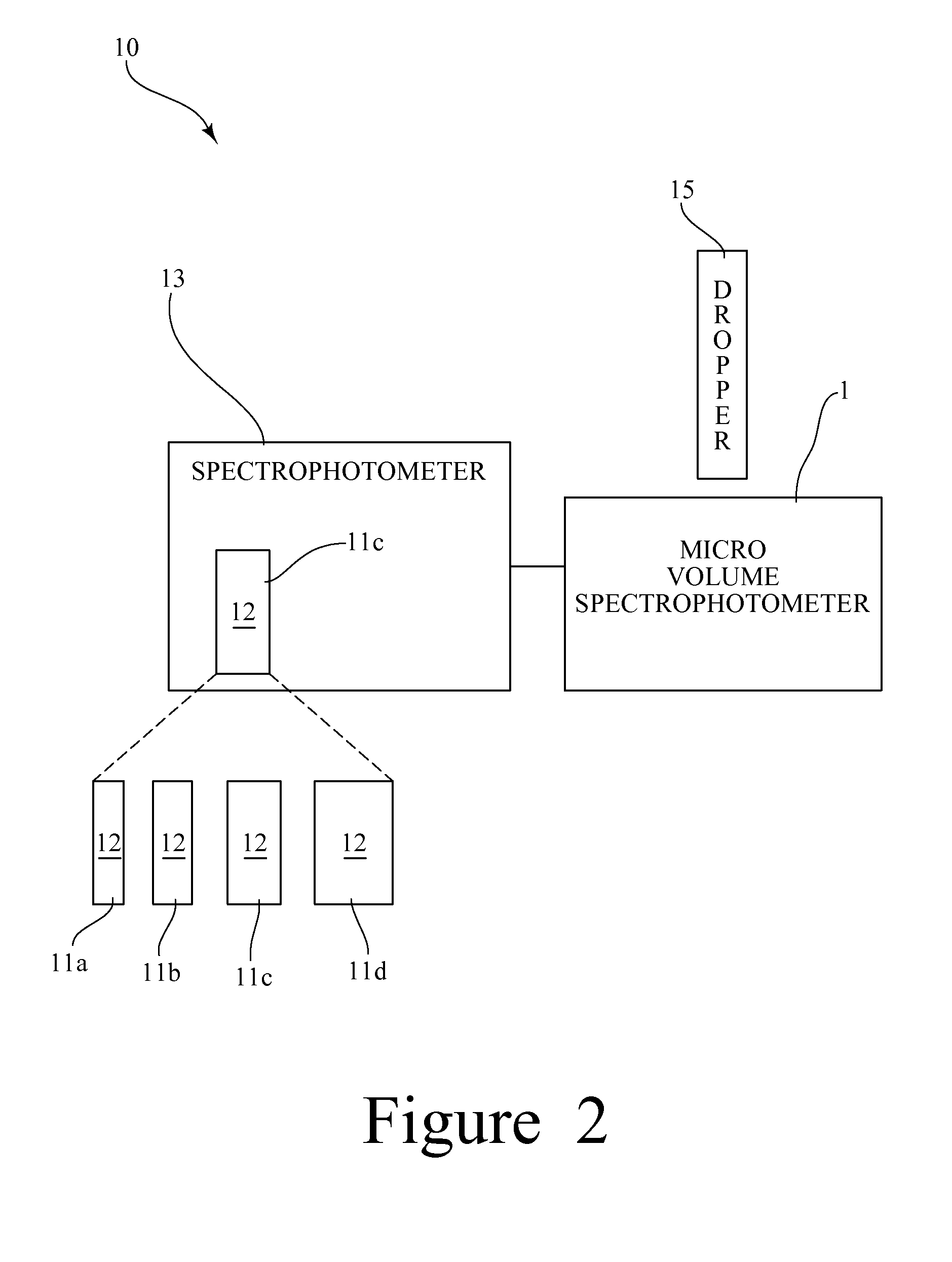

Method for determining the path length of a sample and validating the measurement obtained

ActiveUS20130070236A1Less-prone to contaminationLess-prone to noiseTransmissivity measurementsColor/spectral properties measurementsCuvettePath length

A for traceably determining an unknown optical path length of a sample in an optical measuring device comprises the steps of: providing a drop analyser connected to a standard spectrophotometer; providing a certified reference material contained in first and second closed high accuracy cuvettes; measuring absorbance of the certified reference material to obtain a first absorbance measurement for the first specified path length; measuring absorbance of the certified reference material for a second path length to obtain a second absorbance measurement; using a dropping device to drop a specified volume of the solvent on an optical surface so that the path length of the specified volume can be determined by reference to the first and second absorbance measurement; and using the dropping device to drop the same volume of sample as the specified volume of solvent on the optical measuring device.

Owner:STARNA SCI

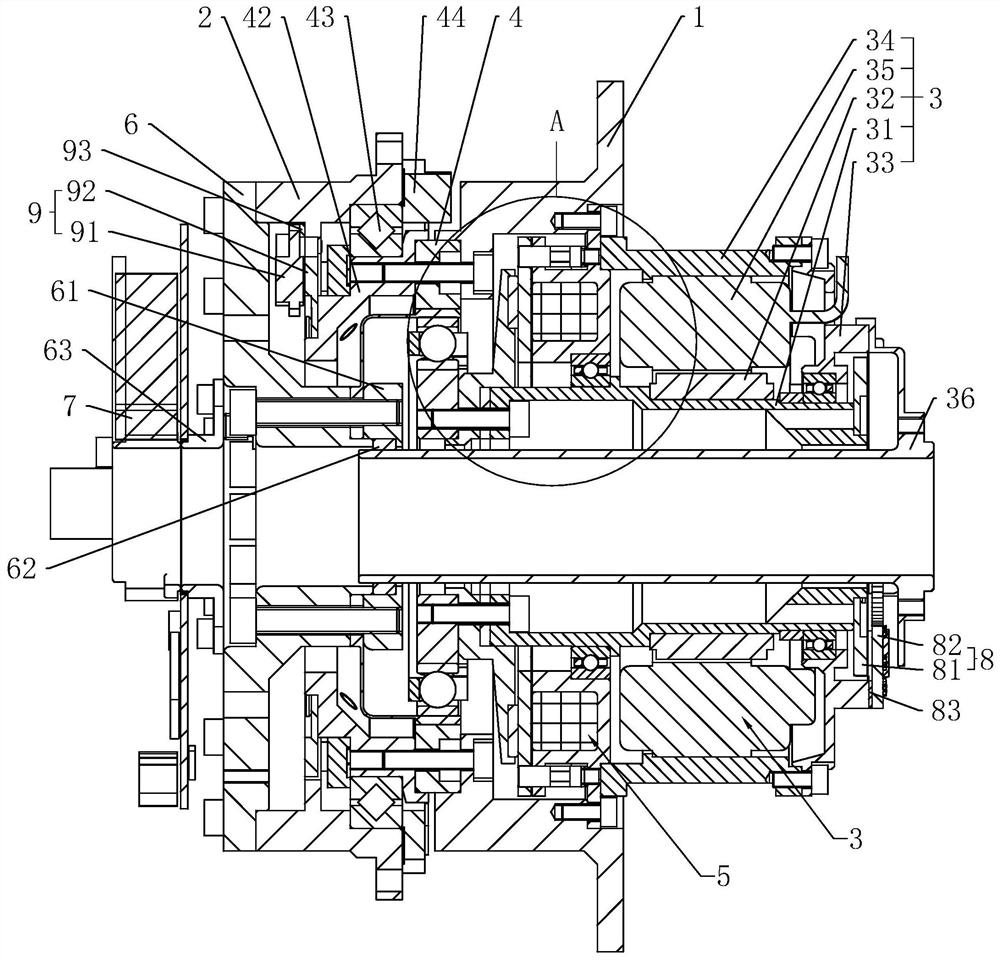

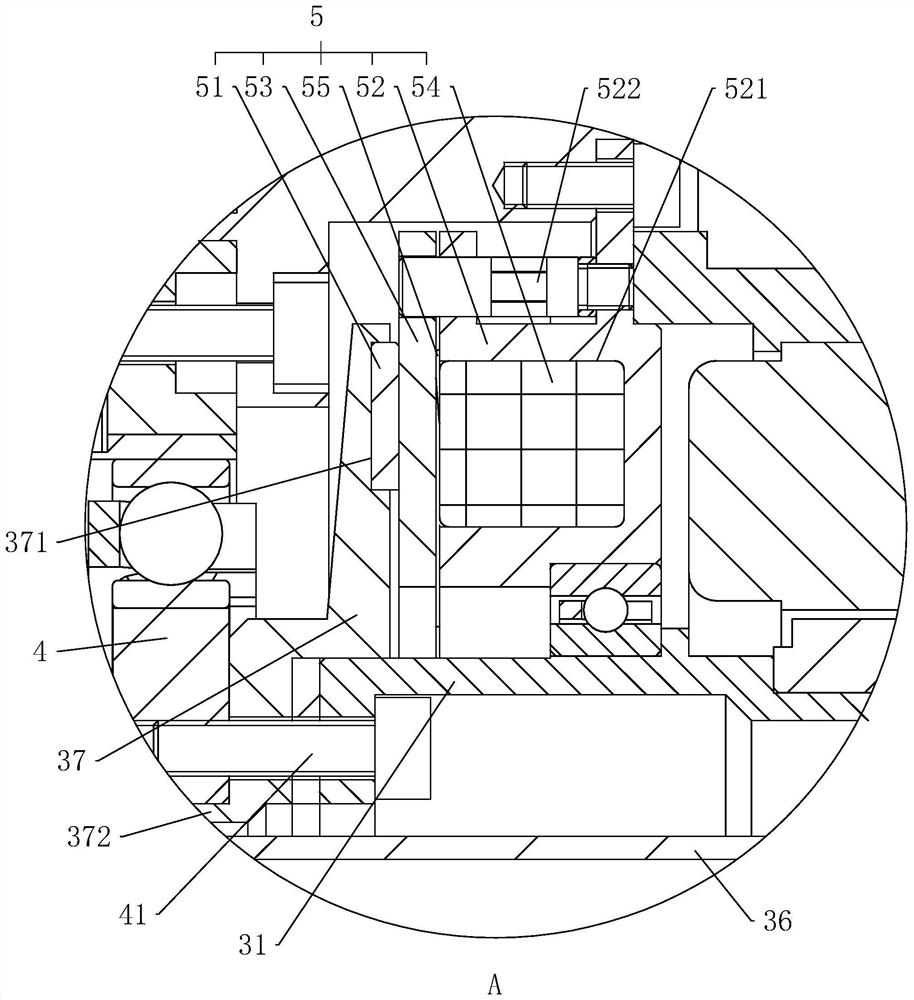

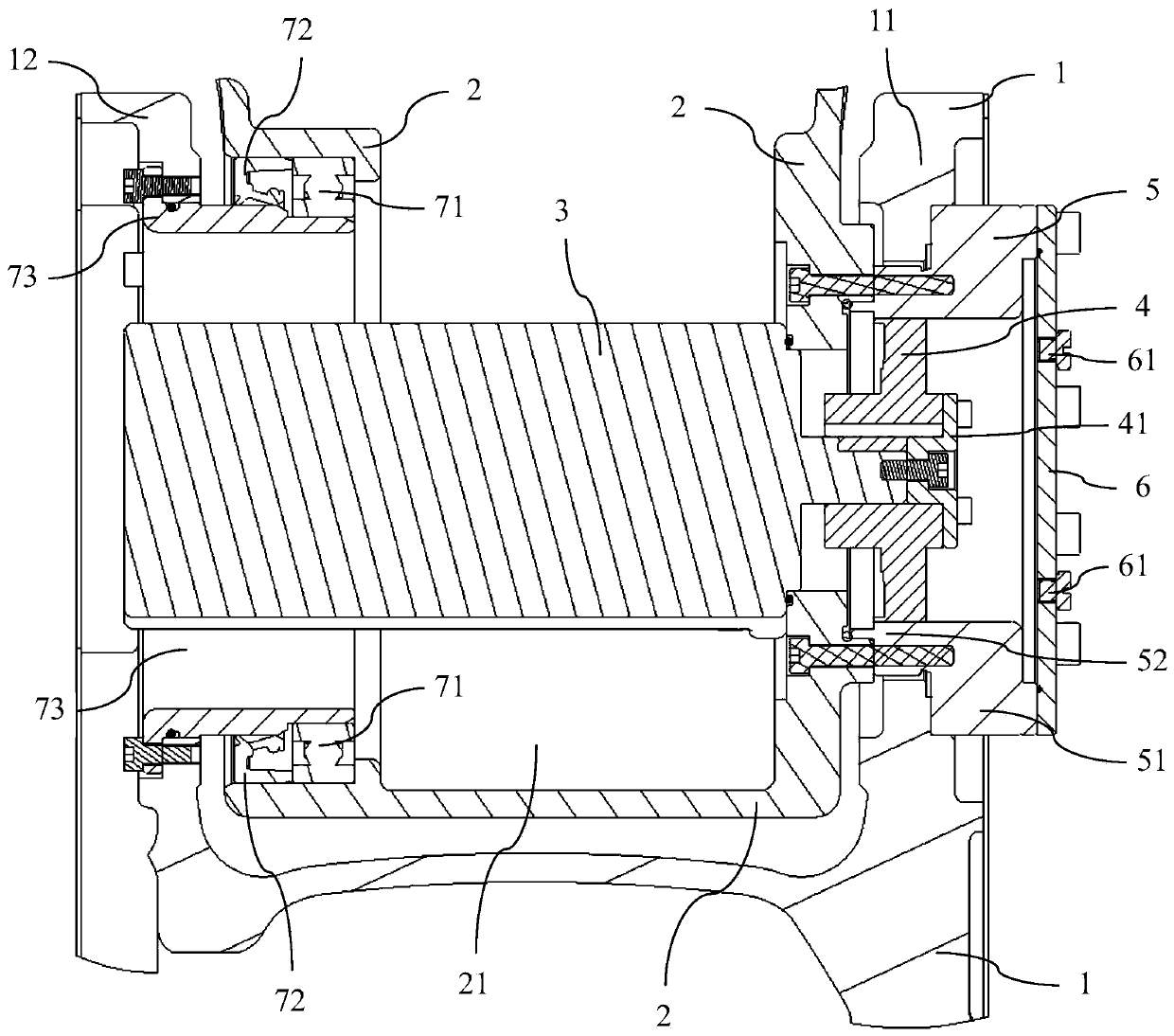

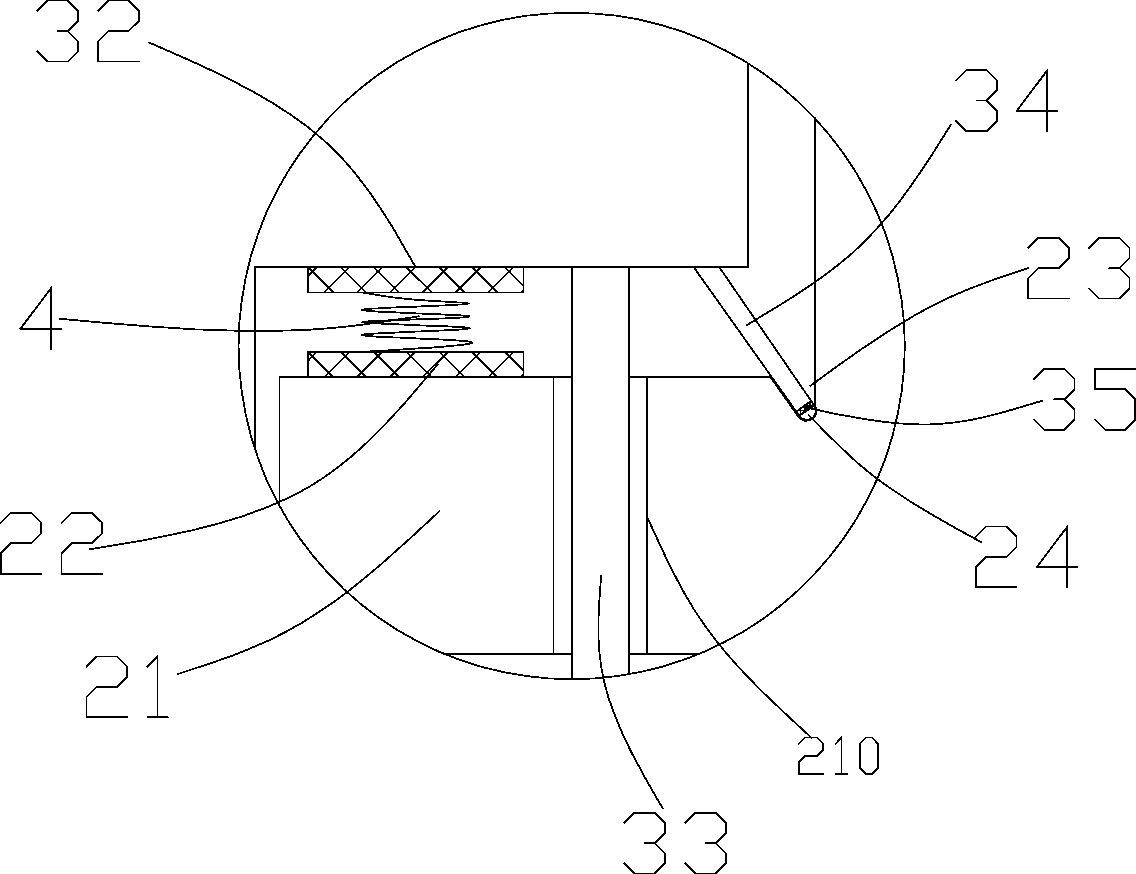

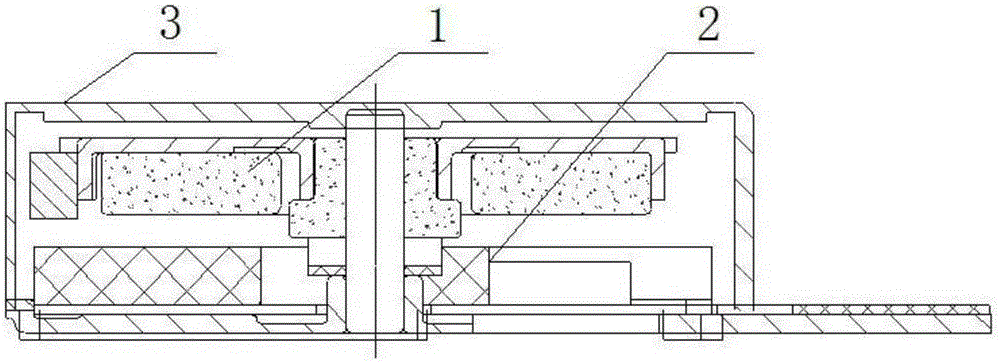

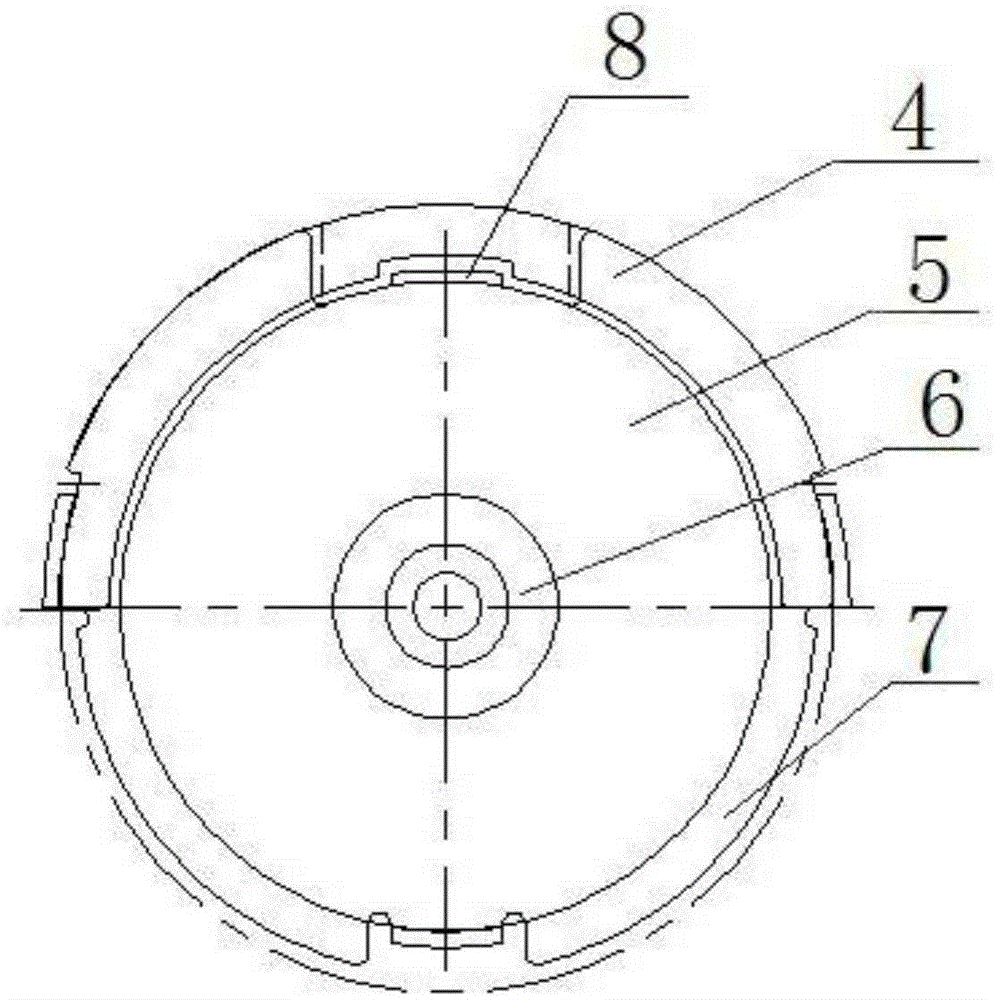

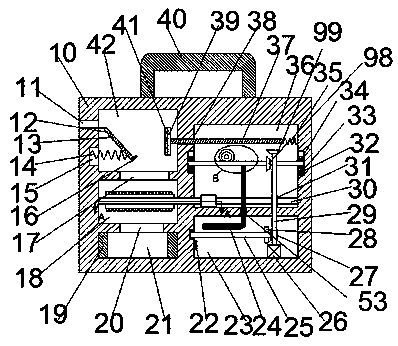

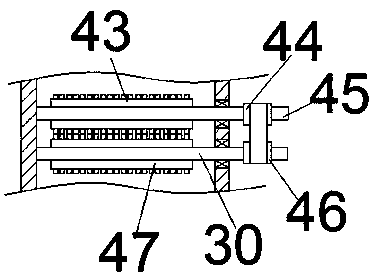

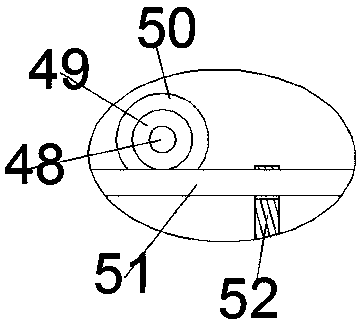

Low-noise modular joint of cooperative robot

The invention relates to a low-noise modular joint of a cooperative robot. The low-noise modular joint of the cooperative robot comprises an inner ring shell, a drive mechanism, a brake mechanism, a harmonic speed reducer, an outer ring shell and a joint servo driver, wherein the drive mechanism comprises a motor shaft, a motor rotor, a motor end cover, a motor shell and a motor stator; the brakemechanism comprises a friction plate, a mounting seat, a brake piece, an electromagnet and an elastic piece, the elastic piece drives the brake piece to move towards the friction plate, and the electromagnet attracts the brake piece to be far away from the friction plate; a drive end of the harmonic speed reducer is fixedly connected with the motor shaft, and a fixed end of the harmonic speed reducer is fixedly connected with the inner ring shell; and the outer ring shell is coaxially connected with the motor shaft, and is connected with a flexible end of the harmonic speed reducer. When a joint normally works, the electromagnet attracts the brake piece, therefore, the relative axial position of the brake piece and the friction plate cannot be changed, the brake piece and the friction plate cannot be scratched easily, and noise cannot be generated easily when the joint works.

Owner:敬科(深圳)机器人科技有限公司

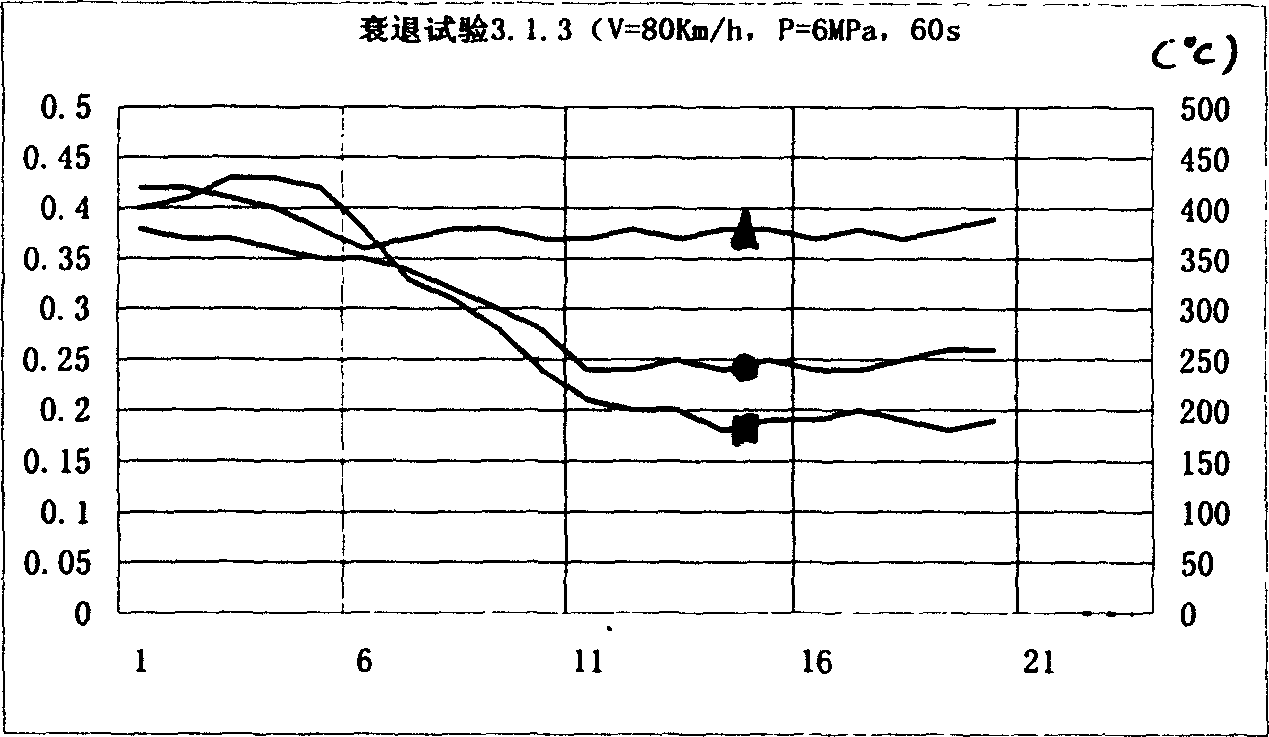

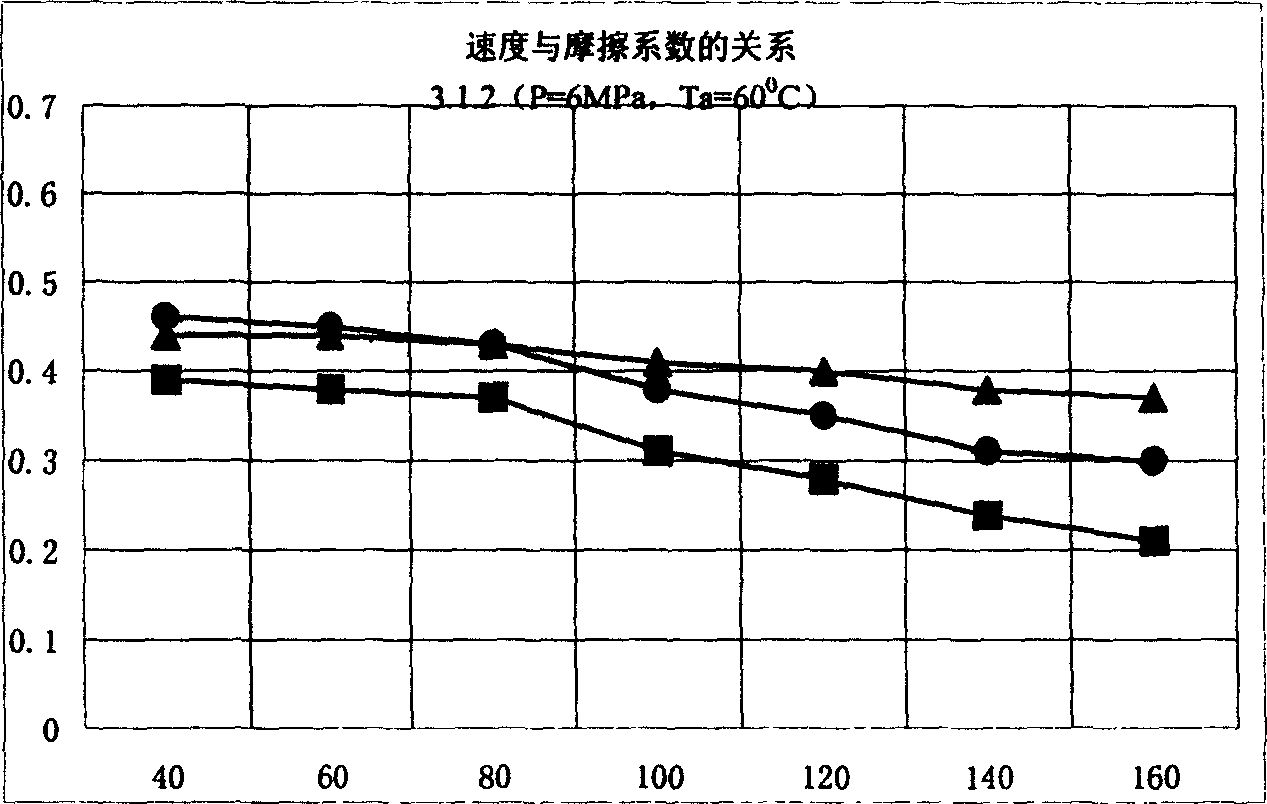

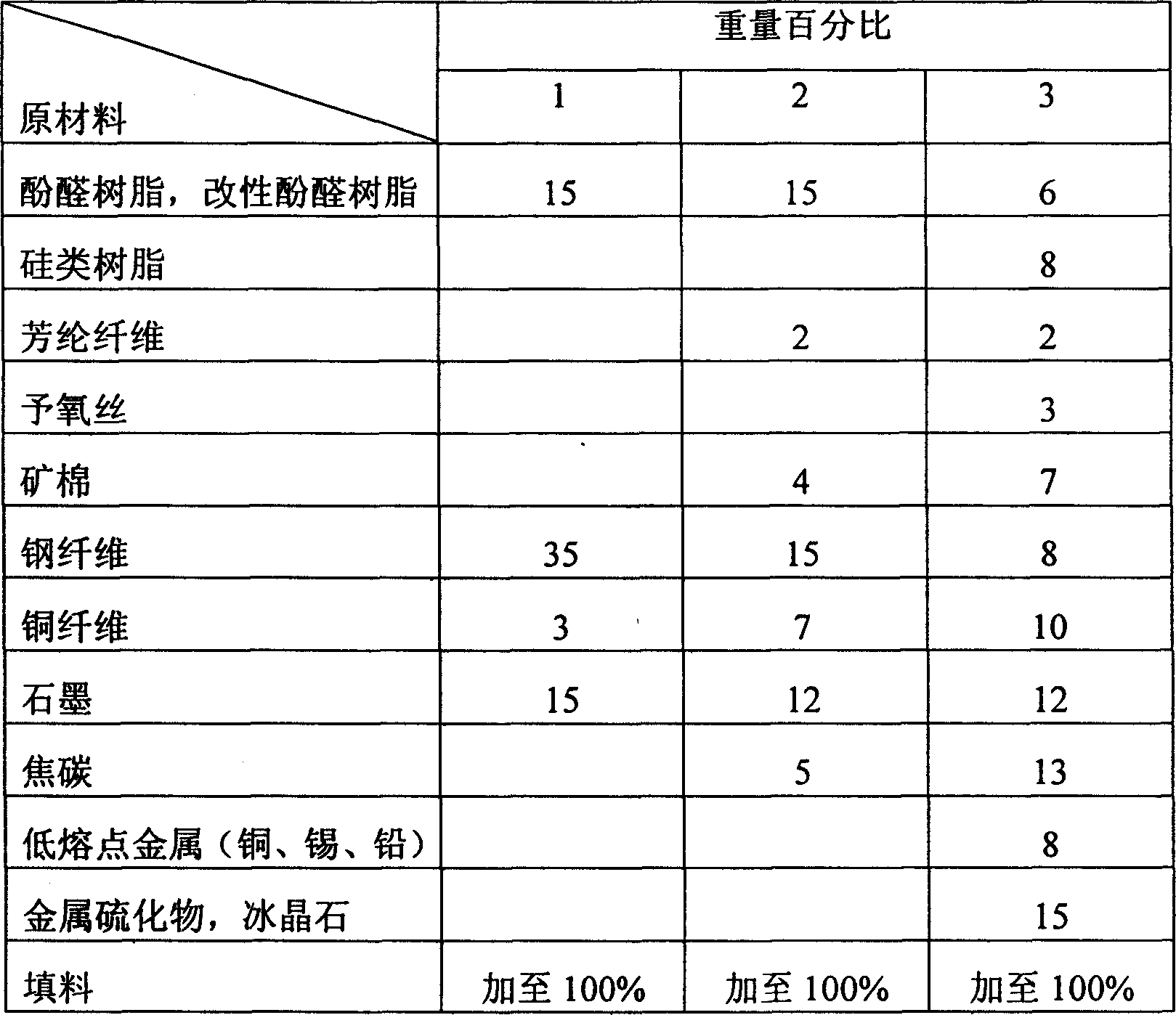

High carbon semi-ceramic braking material

Owner:上海华化摩擦材料有限公司

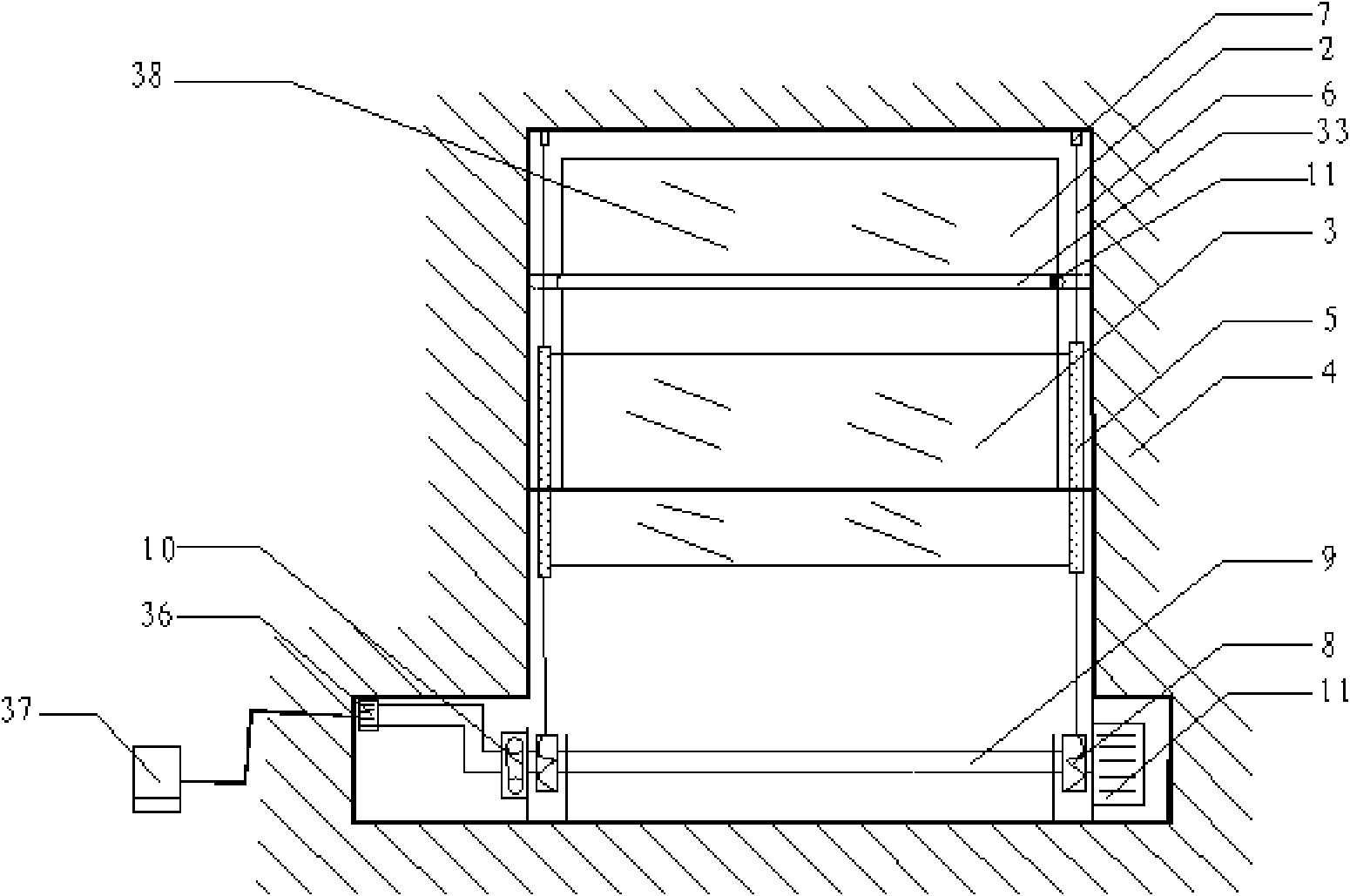

Combined type energy-saving window

InactiveCN101560868AImprove comfortAchieve the effect of enteringDoor/window protective devicesVentilation arrangementWindow shutterEngineering

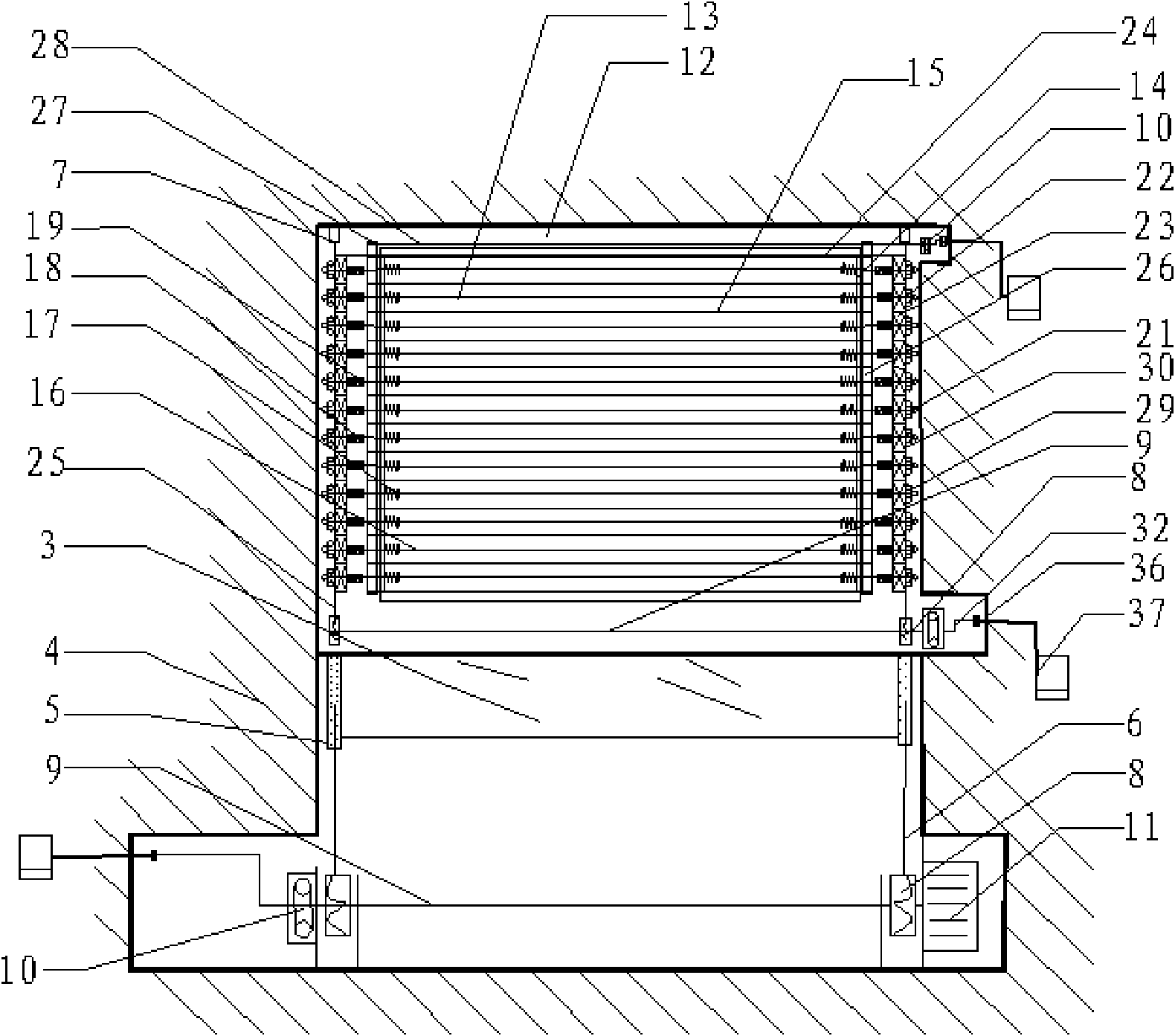

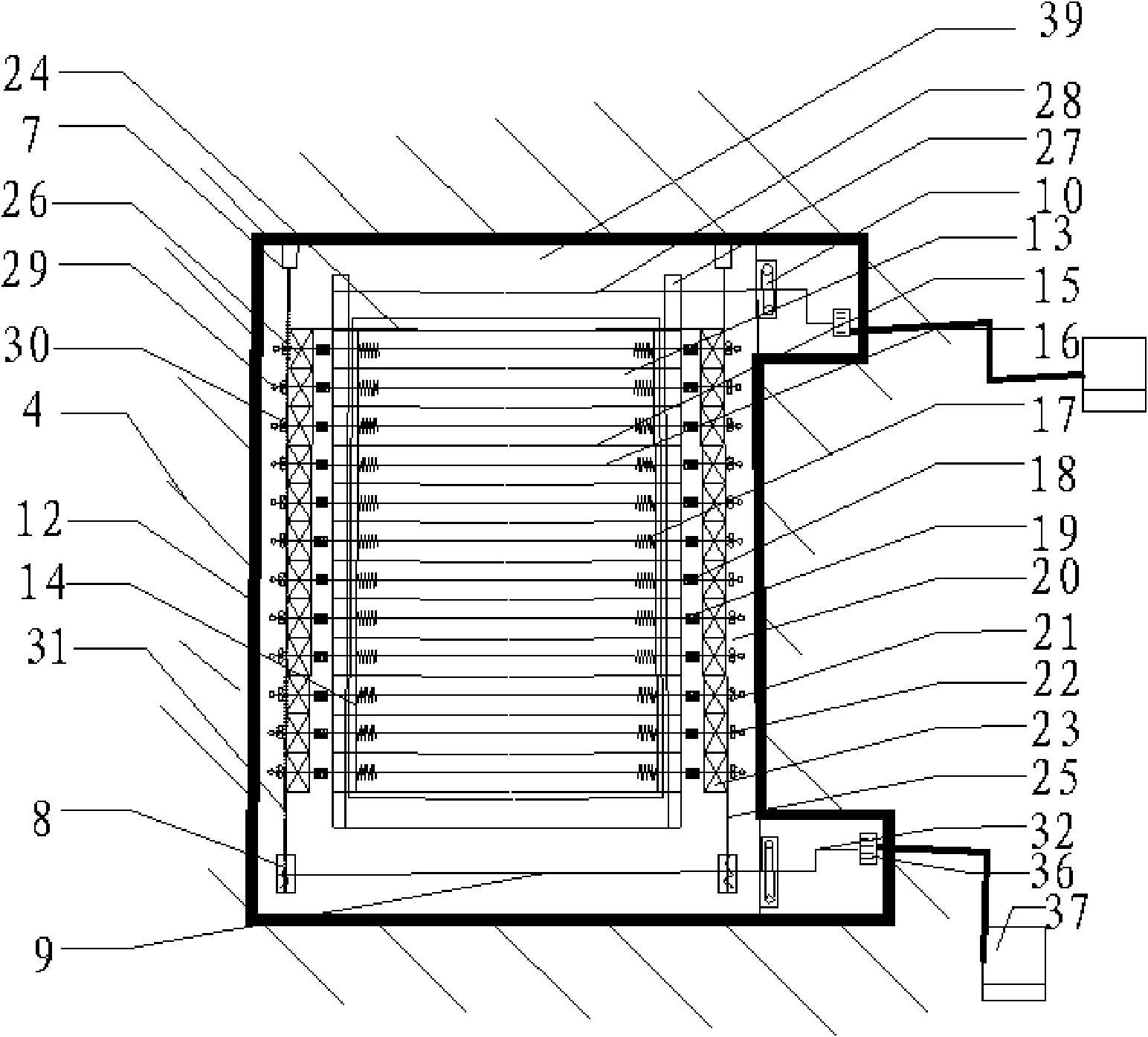

The invention relates to a combined type energy-saving window which comprises a glass window arranged at the inner side of a window hole and a blind arranged at the outer side of the window hole. The glass window is a lift-type glass window. A piece of lifting glass is clamped tightly by a strip-shaped clamping plate and is lifted and dropped by using a steel wire rope, a pulley and a turbine worm assembly. Three steel wires are arranged inside each blade of the blind, the steel wires at the two lateral sides of each blade are connected with hinge sheets which are connected with an angle regulator arranged at the top of a window frame so as to realize the angle control of the blades. The middle steel wires of the blades are connected with a connecting rod of a universal wheel by spring sleeves, the connecting rod of the universal wheel is sleeved with a retraction sheet, and the lifting pulley of the universal wheel moves upwards and downwards along a sliding way; the upper end of the retraction sheet is fixed on a fixing rod, and the lower end thereof is fixed with a lifting rope; and the blind is lifted and dropped by using the lifting rope, the pulley and the turbine worm assembly. The combined energy-saving window has the advantages of capability of automatic operation, great lighting and ventilation quantity, energy conservation, safe performance and beautiful appearance.

Owner:沈洪

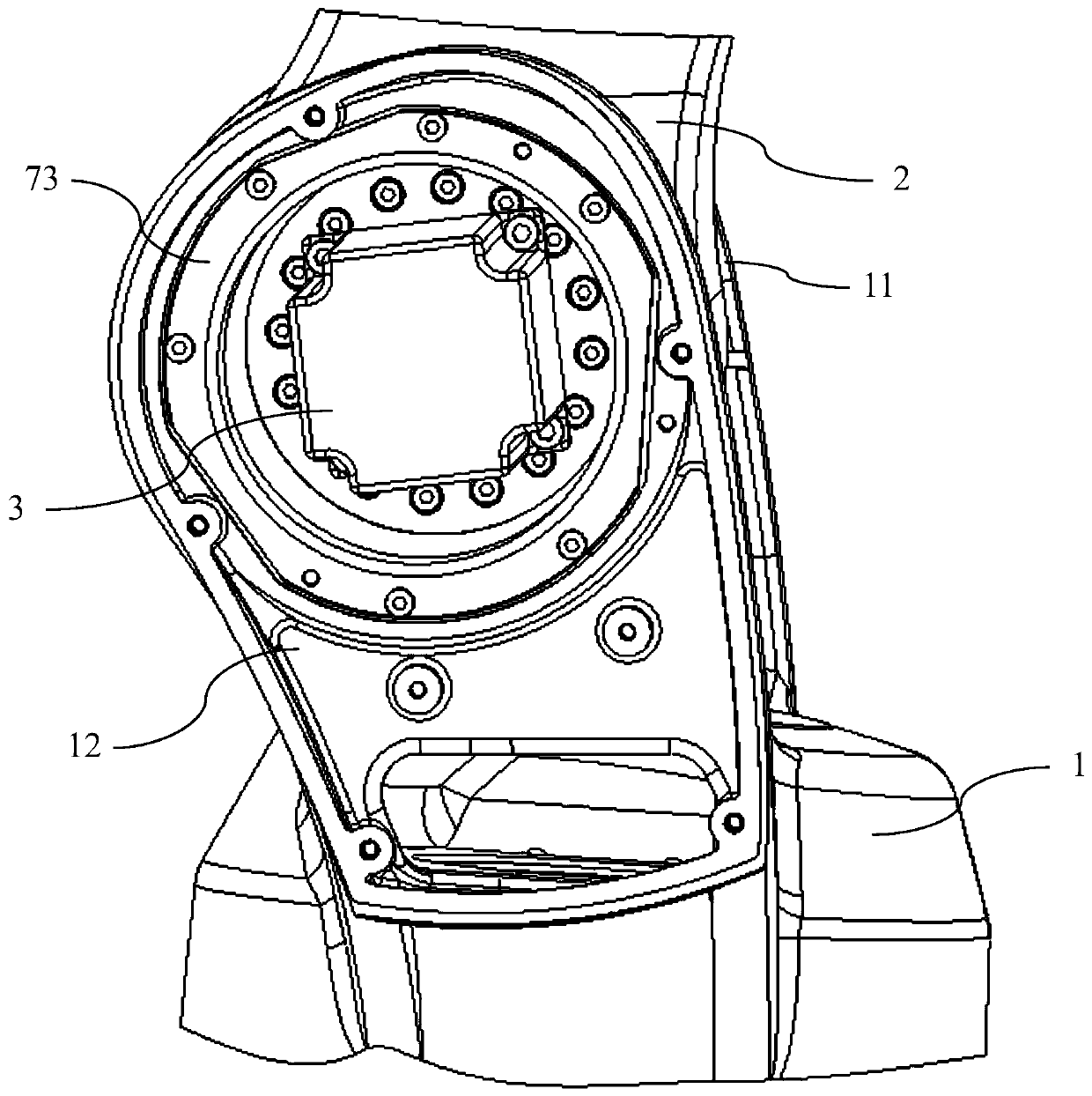

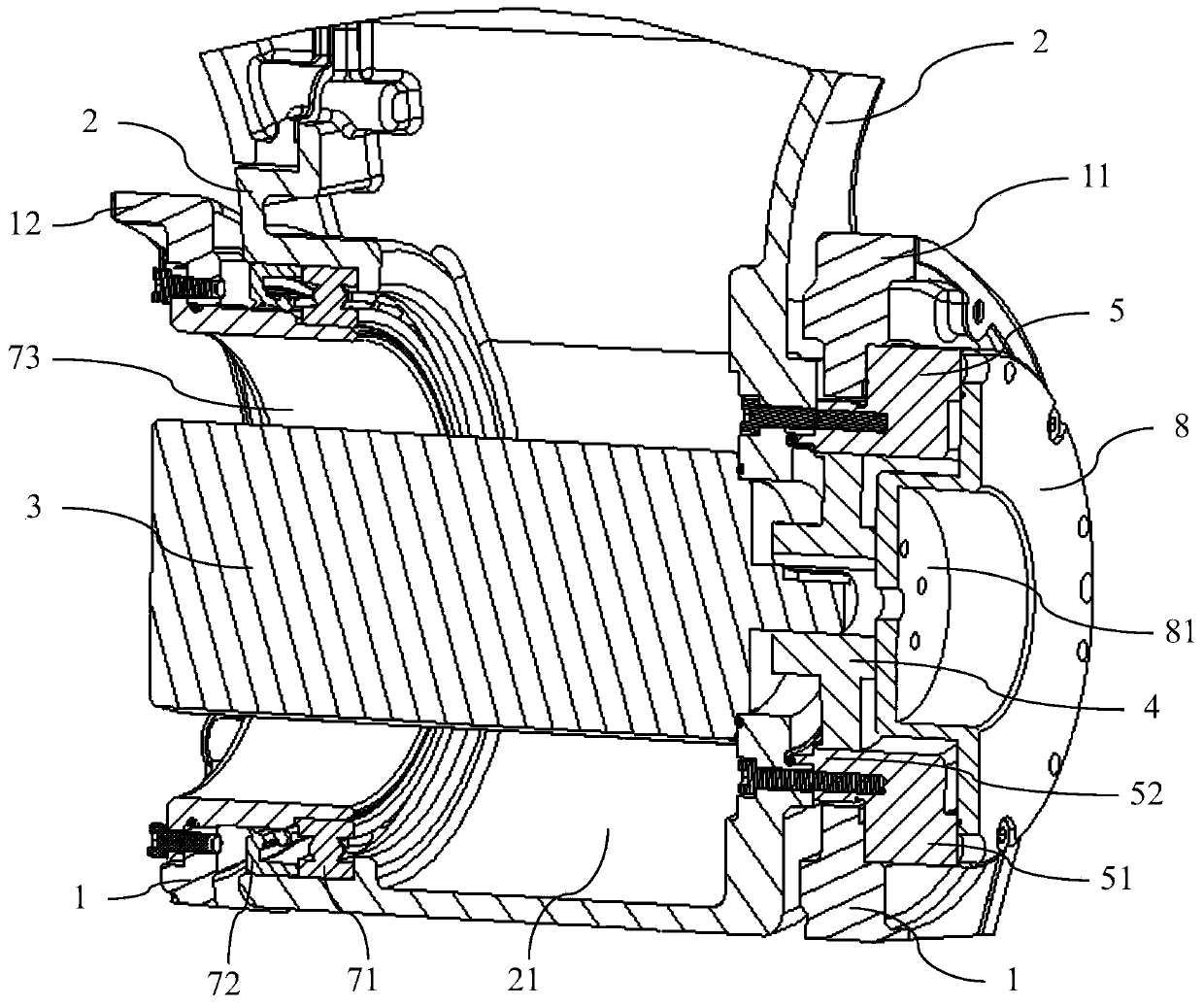

Robot joint structure and robot joint structure assembly method

ActiveCN110000808AReduce volumeStrong designabilityProgramme-controlled manipulatorJointsReducerDrive motor

The invention provides a robot joint structure and a robot joint structure assembly method. The robot joint structure comprises a rocker arm and a base, the rocker arm comprises a mounting cavity, therobot joint structure comprises a driving motor, a wave generator and a reducer rigid and soft wheel member, and the wave generator is mounted to the reducer rigid and soft wheel member; the reducerrigid and soft wheel member is installed in the manner that a first part is fixed to the rocker arm and a second part is fixed to the base, and the reducer rigid and soft wheel member is located at afirst end opening of the mounting cavity; and the driving motor is inserted into the mounting cavity from a second end opening of the mounting cavity and is fixed to the rocker arm, and an output shaft of the driving motor is directly in matched transmission with an inner hole of the wave generator. By means of the robot joint structure and the robot joint structure assembly method, the output shaft of the driving motor is directly connected to the inner hole of the wave generator, the size of the robot joint structure can be decreased, and the designability of the applicable range and the volume is improved.

Owner:SHENZHEN INOVANCE TECH

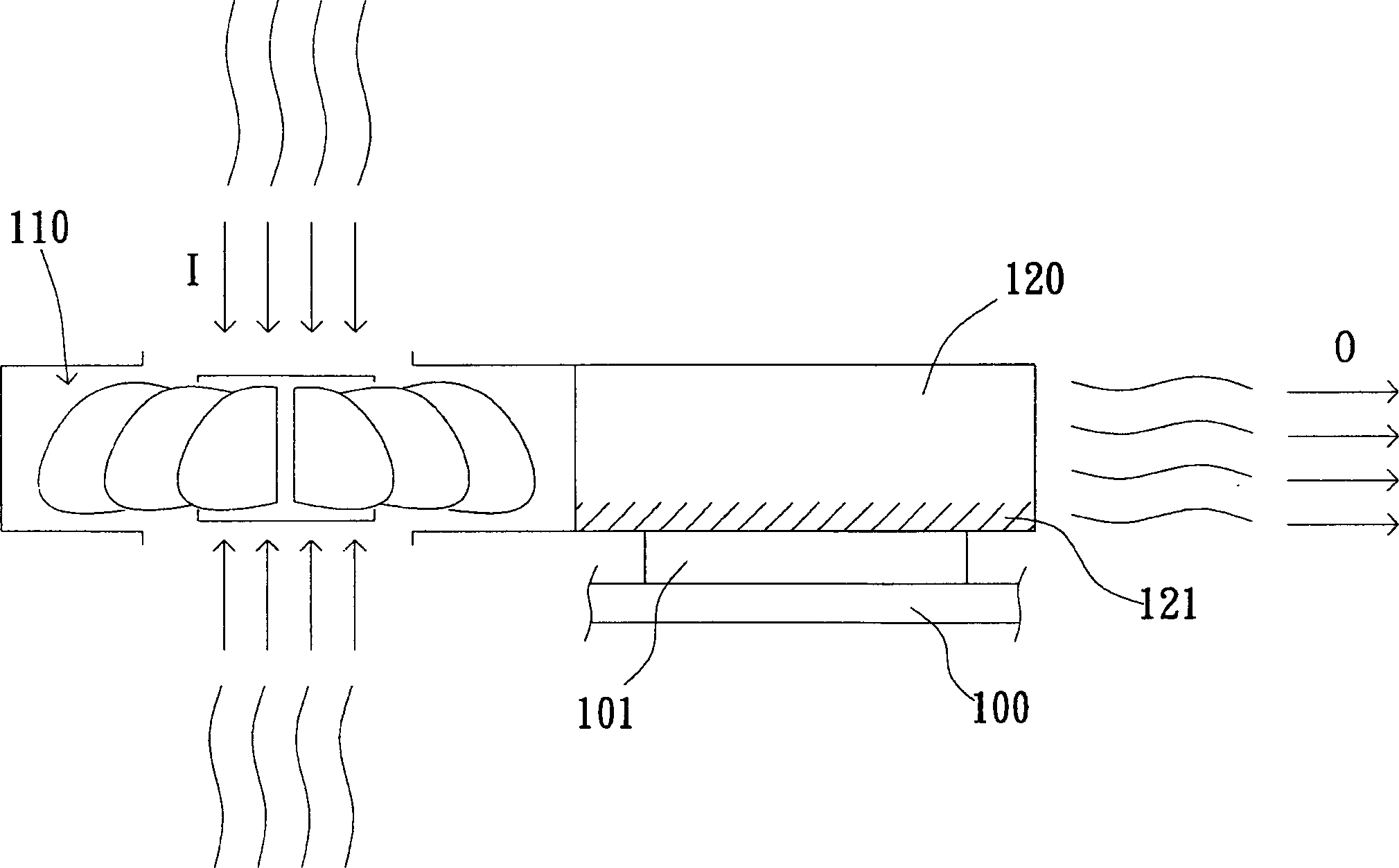

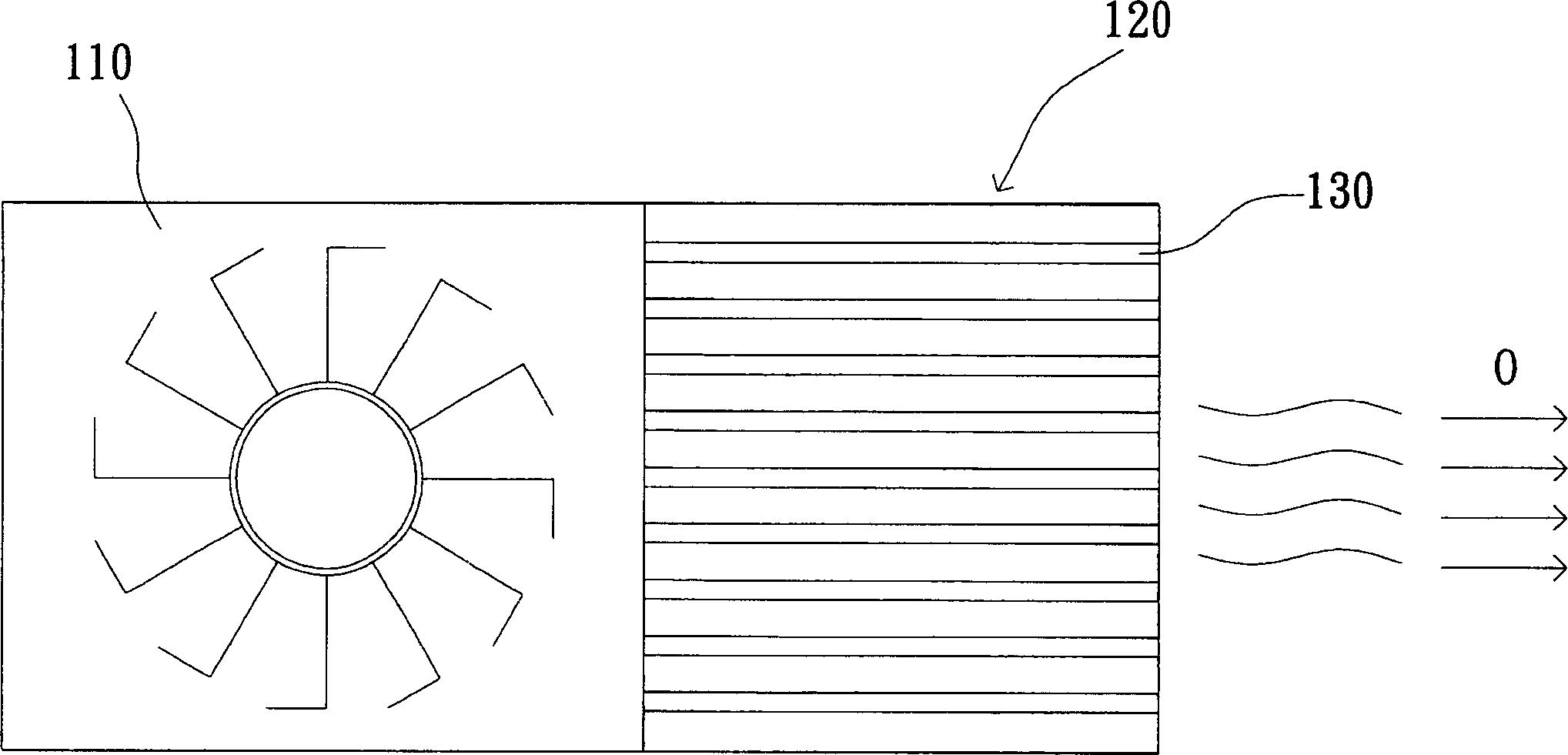

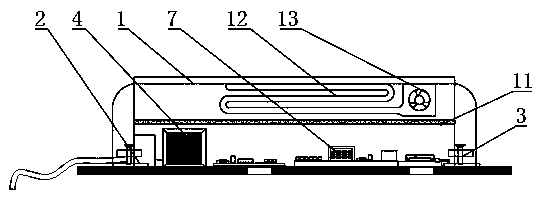

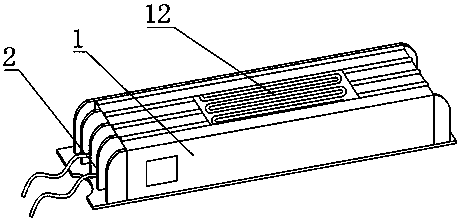

Heat dissipating module of notebook computer

InactiveCN1410860ASimple designLarge air volumeDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingComputer module

The heat emission module of the notebook computer is utilzied to lower the surface temperature of the chips inside the notebook computers. The heat emission module includes following parts. The fan is installed inside computer, including the first and second wind outlets. The air sucked by the fan is discharged through the first and second wind outlets. The first radiator is set at the first outlet, the bottom of the first radiator is contact with the chips for carrying out the heat exchange. The second radiator is set at the second outlet. The heat conducting structure is connected to the first radiator and the second radiator in parallel and utilized to transfer the heat from the first radiator to the second radiator.

Owner:WISTRON CORP

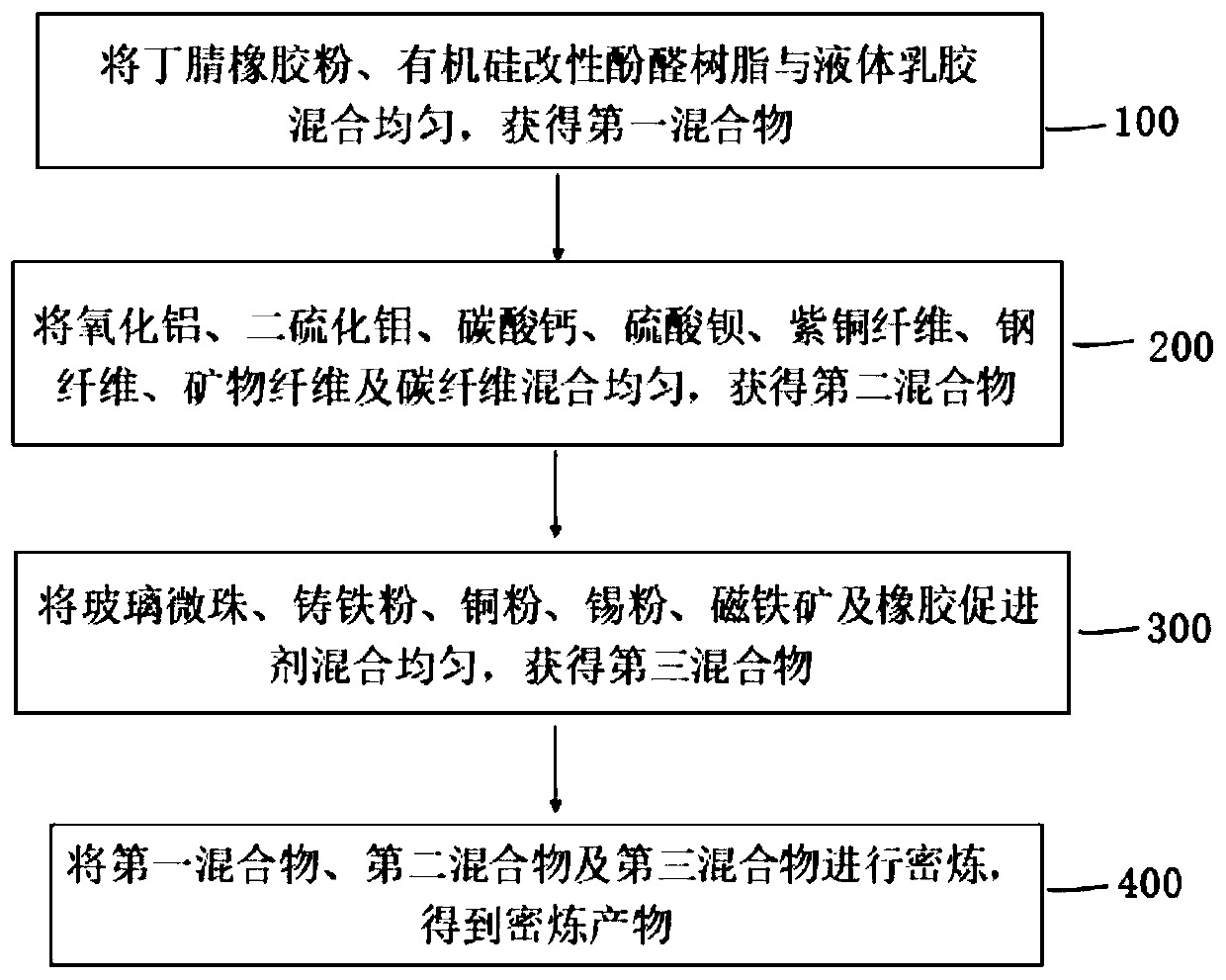

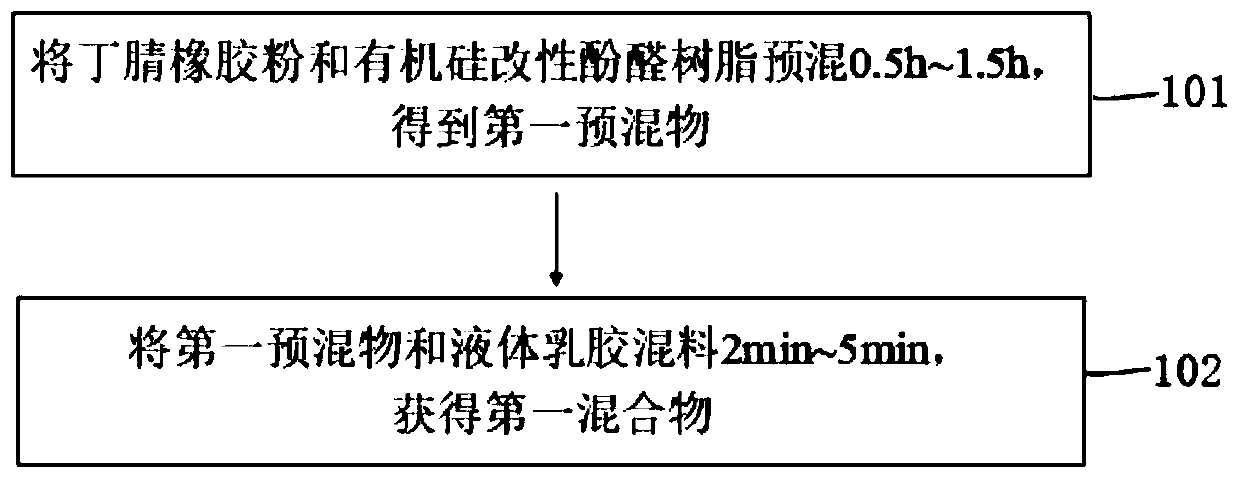

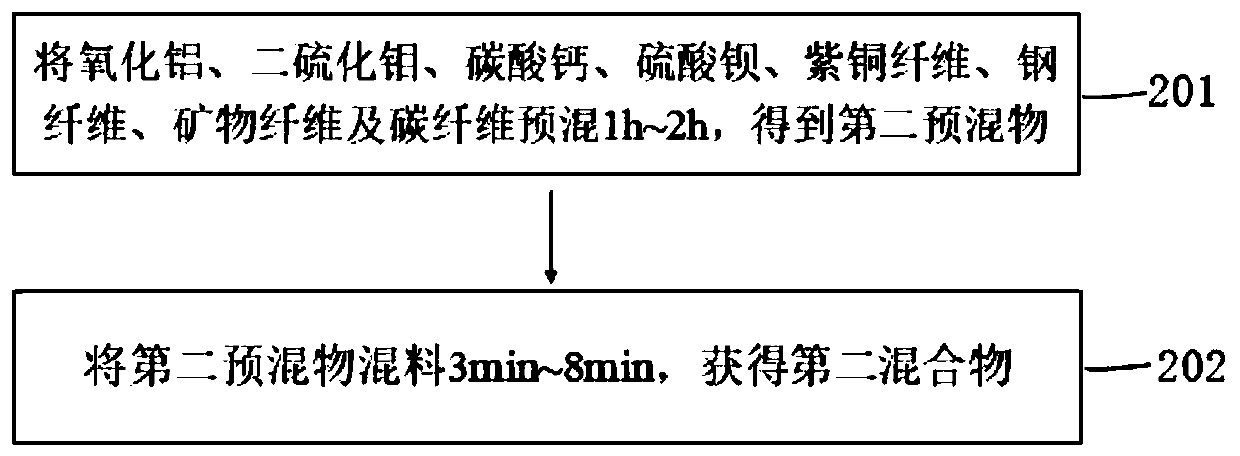

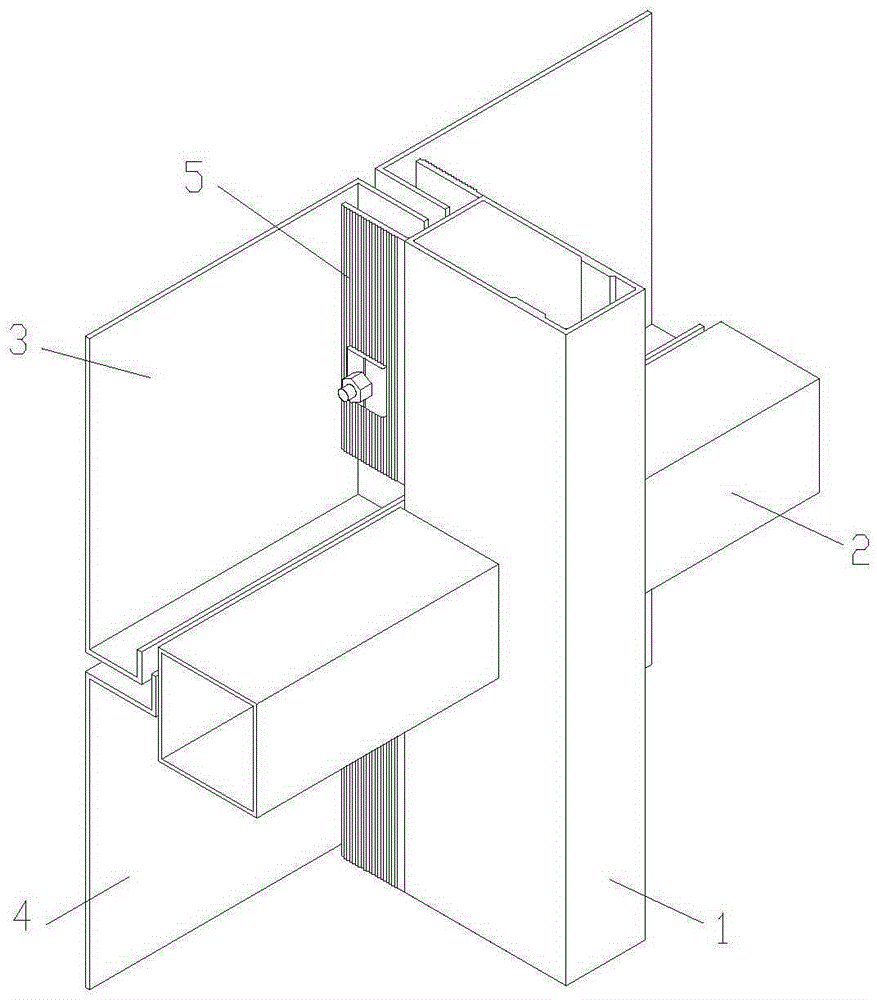

Organic synthesis friction body, brake pad and preparation method of organic synthesis friction body and brake pad

PendingCN111536180AStable coefficient of frictionEasy to wearFriction liningActuatorsOrganic synthesisElectric machinery

The invention discloses an organic synthesis friction body, a brake pad and a preparation method of the organic synthesis friction body and the brake pad, and relates to the field of traffic part machining and manufacturing. According to the brake pad, it is ensures that the brake pad has the characteristics of being wear-resistant and low in thermal conductivity, the brake pad is not prone to generating abnormal wear and noise, the problems of brake distance deviation and brake pad abnormal wear during the braking process of the powder metallurgy brake pad are solved, and the influence of thebrake pad on the rotating speed of a motor is reduced. The brake pad comprises a steel back, the organic synthesis friction body, a plurality of fixing rings and a plurality of material grabbing pins, wherein the organic synthesis friction body is an integrated organic synthesis friction body, the multiple fixing rings and the multiple material grabbing pins each are fixed to the steel back, andthe organic synthesis friction body is fixed to the steel back with the multiple material grabbing pins. The brake pad is applied to urban rail transit transportation aspects.

Owner:北京浦然轨道交通科技股份有限公司 +1

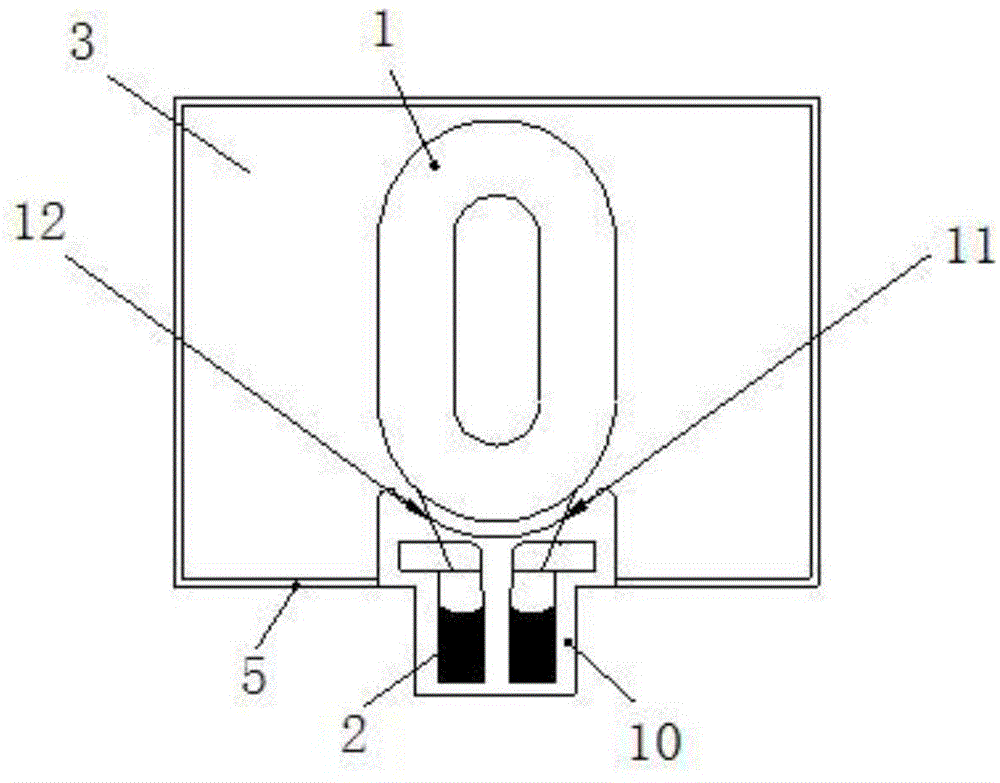

Wavebetter

The invention discloses a wavebetter, and belongs to the technical field of skin brushes. The wavebetter comprises a shell. A large brush head is arranged at the front end of the shell. A circular hole is formed in the middle of the large brush head. A protruding block is arranged on the inner side face of the circular hole. A through hole is vertically formed in the protruding block. A first electromagnet is arranged on the upper end face of the protruding block. A small brush head is arranged in the circular hole. A notch is formed in the side face of the small brush head. A second electromagnetic is arranged on the lower side face of the notch. The first electromagnet and the second electromagnet are connected through a spring. Compared with the prior art, the wavebetter has the advantages that vibration of an output haft of the wavebetter can be directly transmitted to the small brush head, vibration of the small brush head can be enhanced, and when nose wing parts, T-shaped face parts and other deep facial contour parts are cleaned, cleaning force is larger, and cleaning and massage effects are better; the requirement for cleaning a face is met by changing the shape of the brush heads according to actual demands, the performance of the wavebetter is improved, and the wavebetter is not prone to noise, convenient to use and practical.

Owner:SHENZHEN RISUN TECHNOLOGY CO LTD

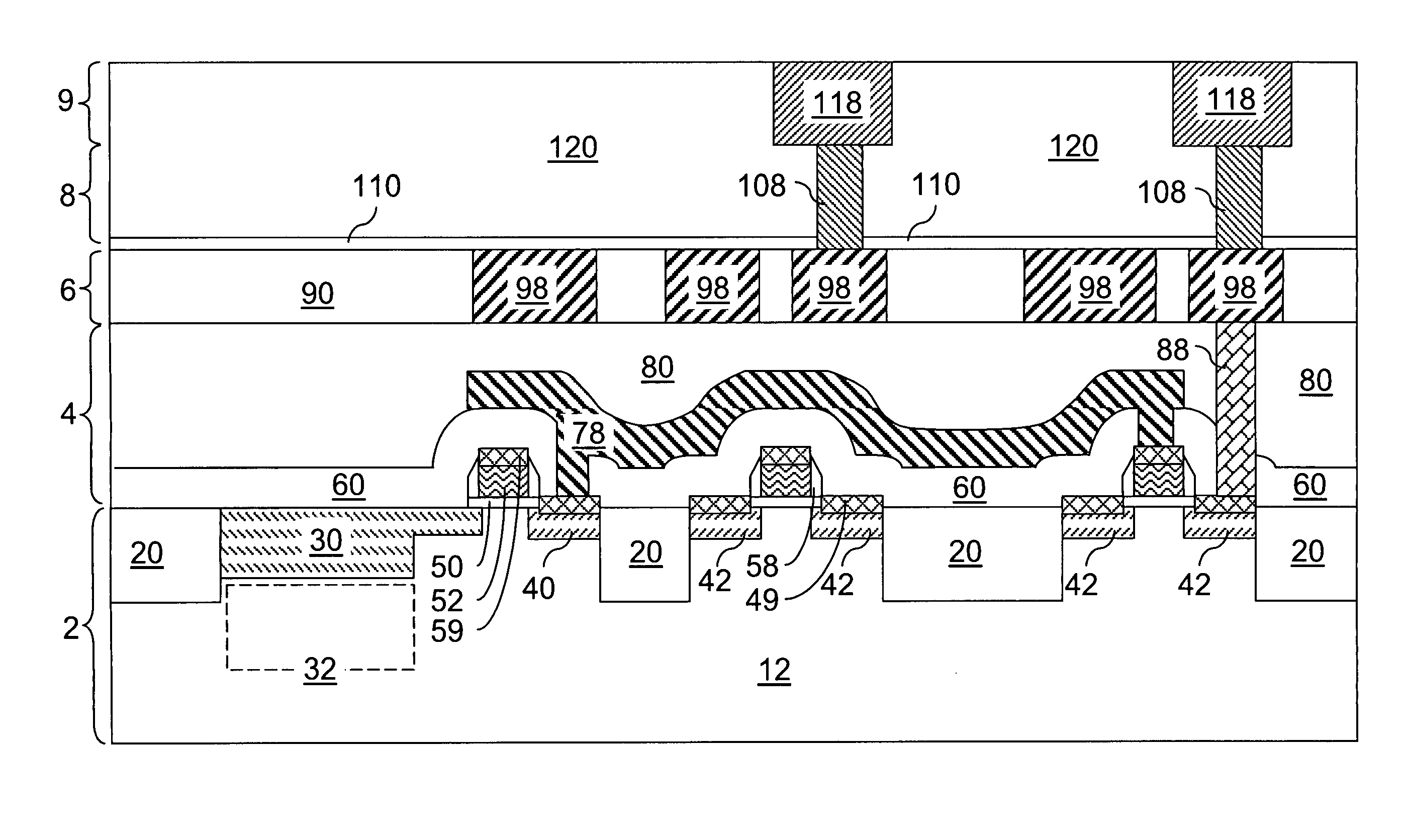

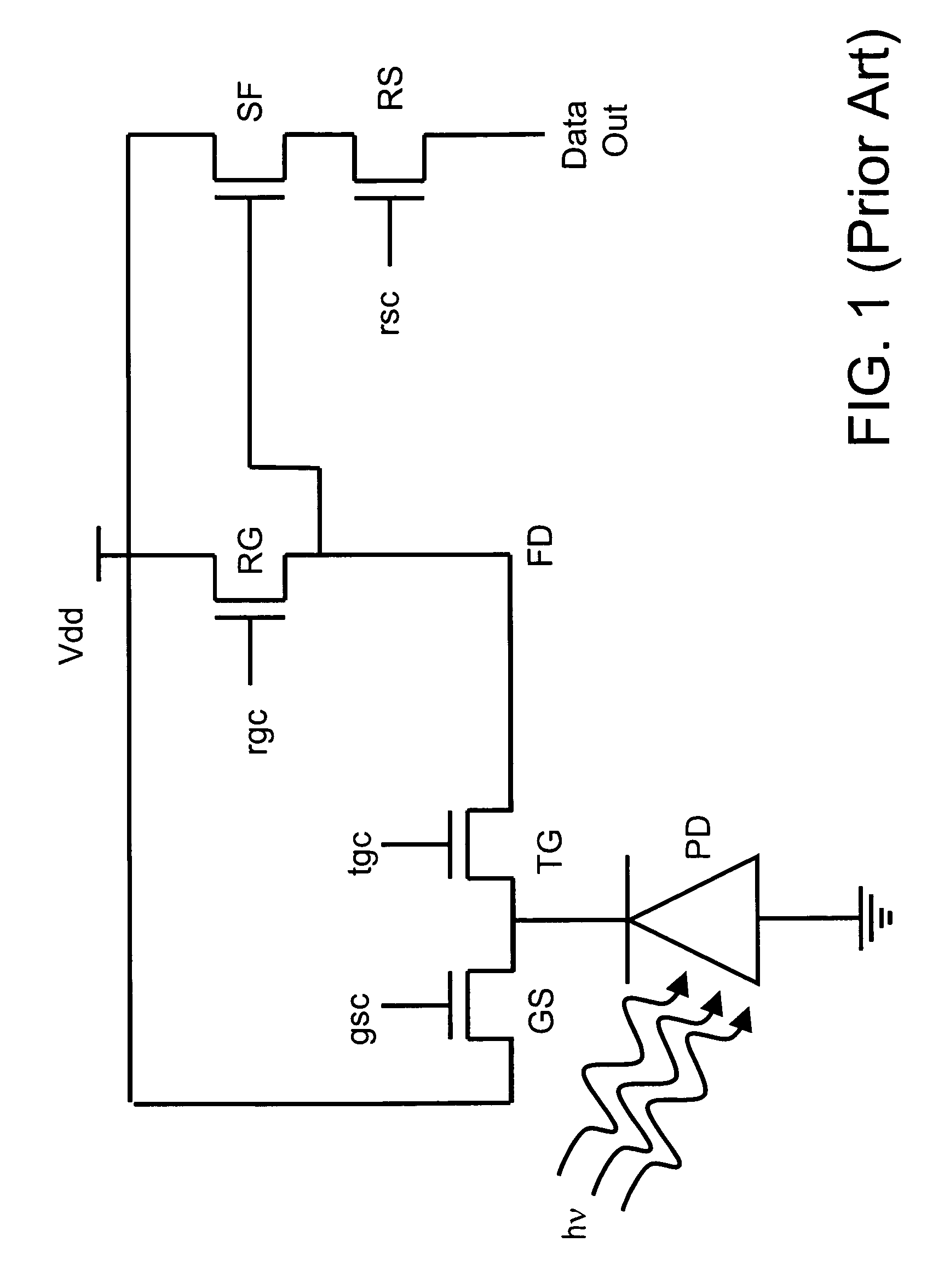

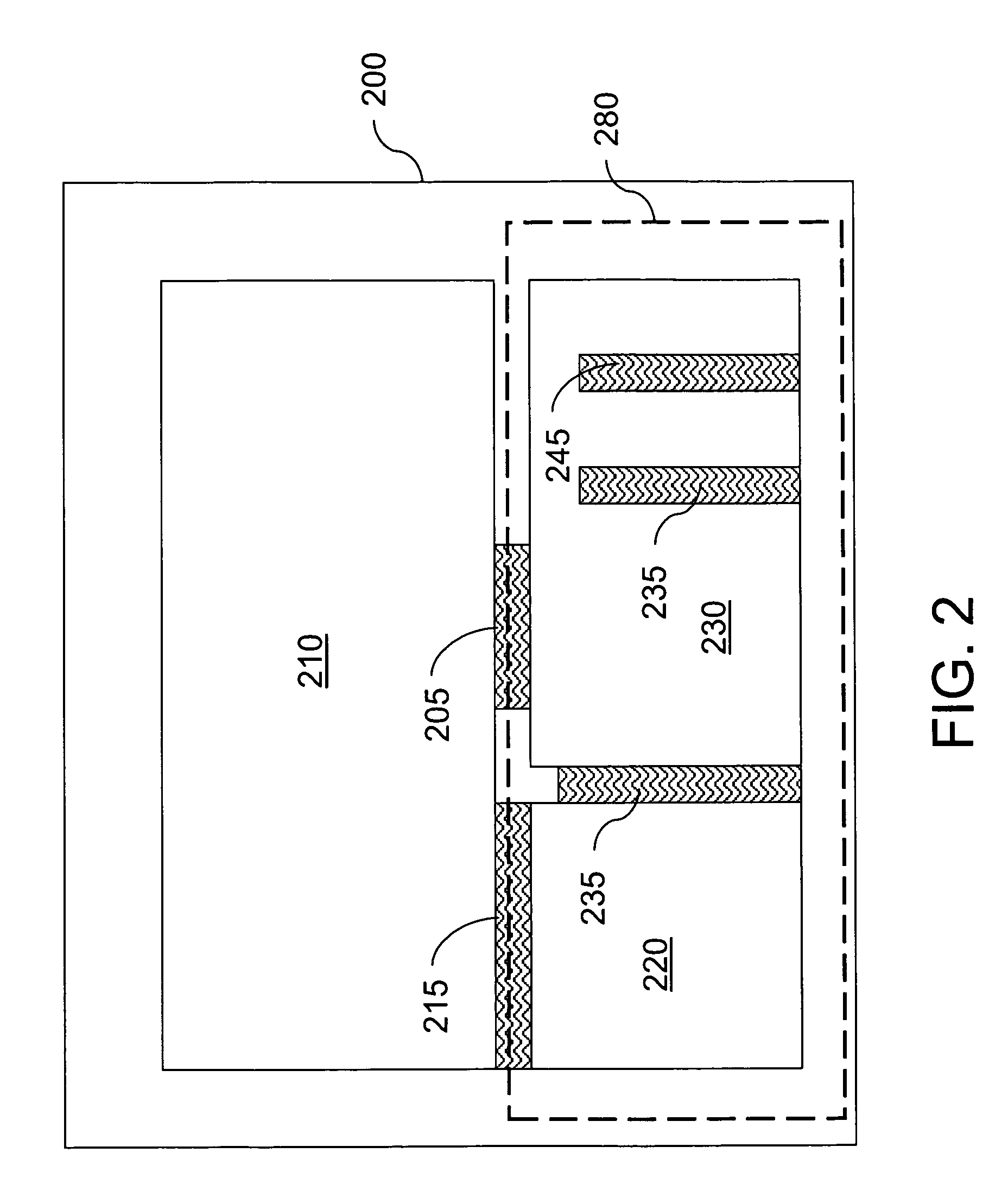

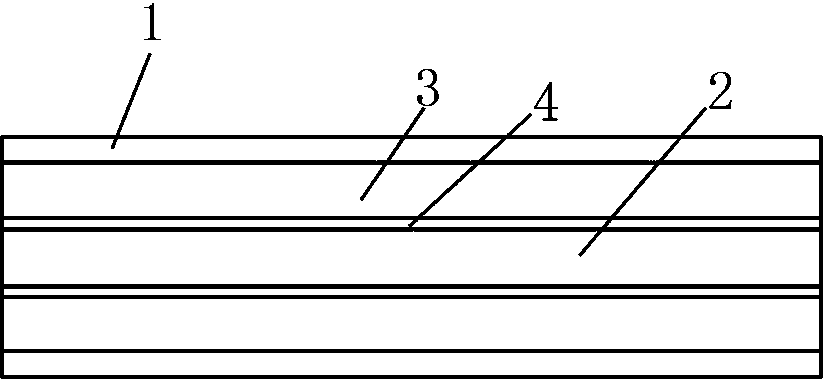

Intralevel conductive light shield

ActiveUS8709855B2Less-prone to noiseSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectDielectric layer

A conductive light shield is formed over a first dielectric layer of a via level in a metal interconnect structure. The conductive light shield is covers a floating drain of an image sensor pixel cell. A second dielectric layer is formed over the conductive light shield and at least one via extending from a top surface of the second dielectric layer to a bottom surface of the first dielectric layer is formed in the metal interconnect structure. The conductive light shield may be formed within a contact level between a top surface of a semiconductor substrate and a first metal line level, or may be formed in any metal interconnect via level between two metal line levels. The inventive image sensor pixel cell is less prone to noise due to the blockage of light over the floating drain by the conductive light shield.

Owner:GLOBALFOUNDRIES US INC

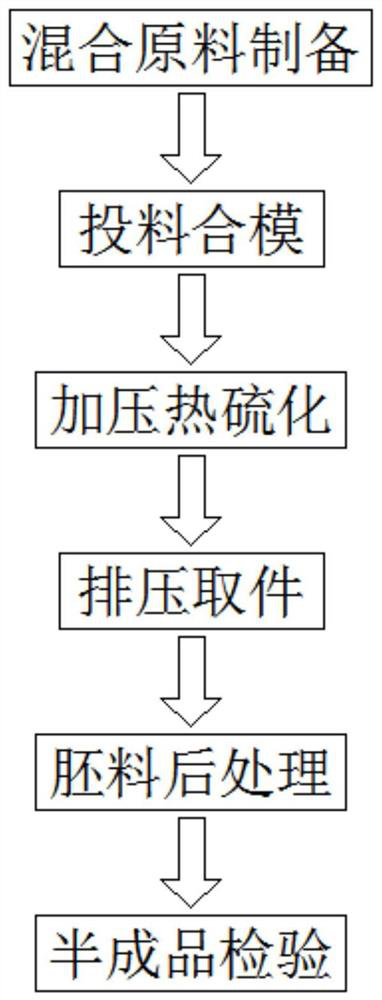

Vulcanization method for producing low-wear carbon fiber automobile clutch friction plate

InactiveCN112123646ALow densityImprove wear resistanceDomestic articlesFriction liningFiberCarbon fibers

The invention discloses a vulcanization method for producing a low-wear carbon fiber automobile clutch friction plate, comprising the steps of preparation of a mixed raw material, feeding and mold assembly, pressurization and heat vulcanization, pressure relief and part taking, blank post-treatment and inspection of a semi-finished product. By adopting an inorganic ceramic fiber material, the friction plate also has better thermal stability and lower thermal conductivity, and meanwhile, each raw material is proportioned by a proportioning machine, so that the proportioning of each raw materialis more accurate, and the preciseness of a vulcanization process is further guaranteed; in addition, the mixed raw material is screened before feeding and mold assembly; one-time hot-press forming isadopted in the hot-press machining process; heat treatment, grinding and polishing are performed on a blank after being formed; and finally, the semi-finished product of the friction plate is detected. Compared with a traditional friction plate vulcanization machining method, the vulcanization method of the invention is simple in procedure, saves the extra cost in the pre-forming process, improves the production efficiency, and improves the mechanization degree of production and machining.

Owner:来安县隆华摩擦材料有限公司

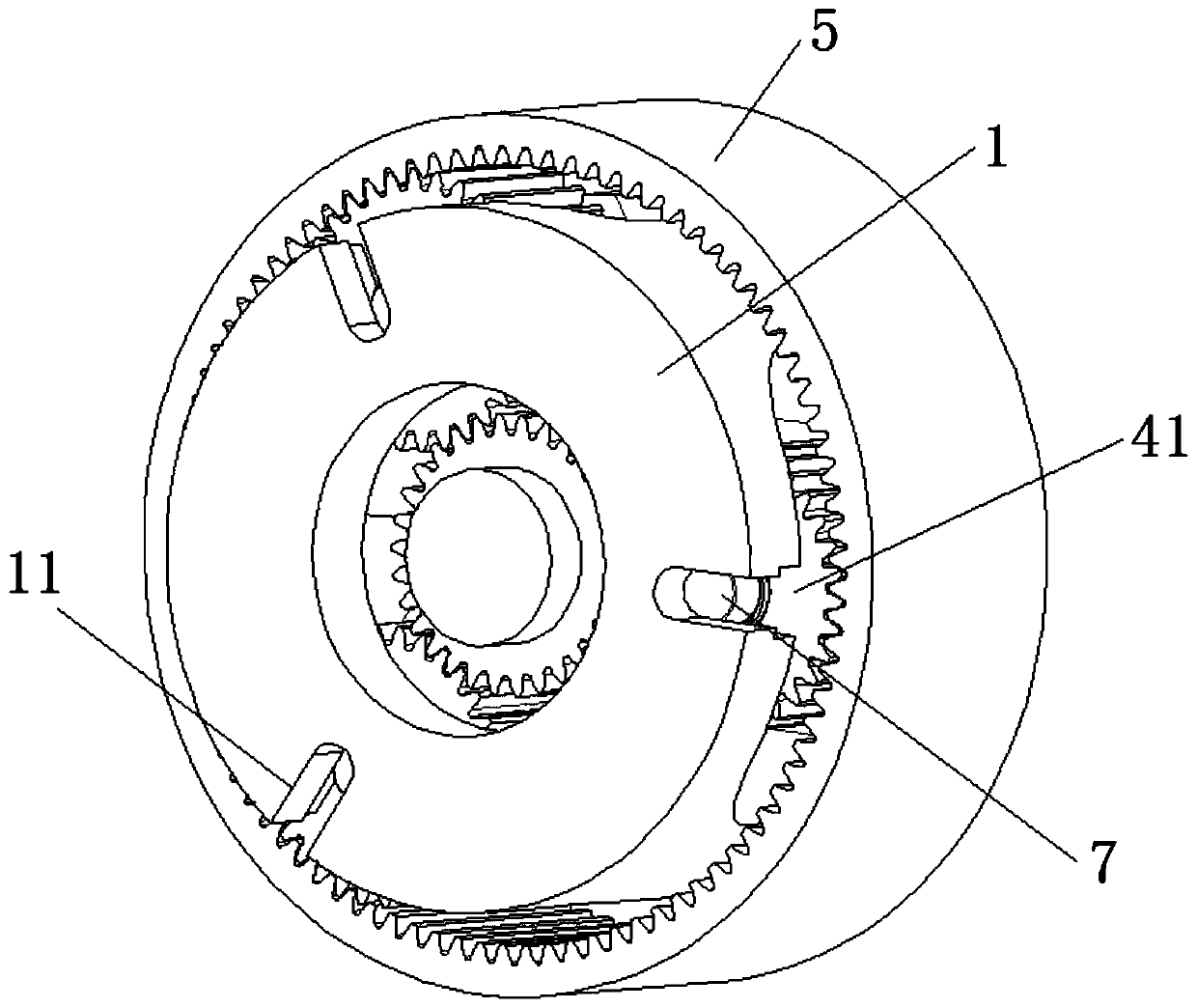

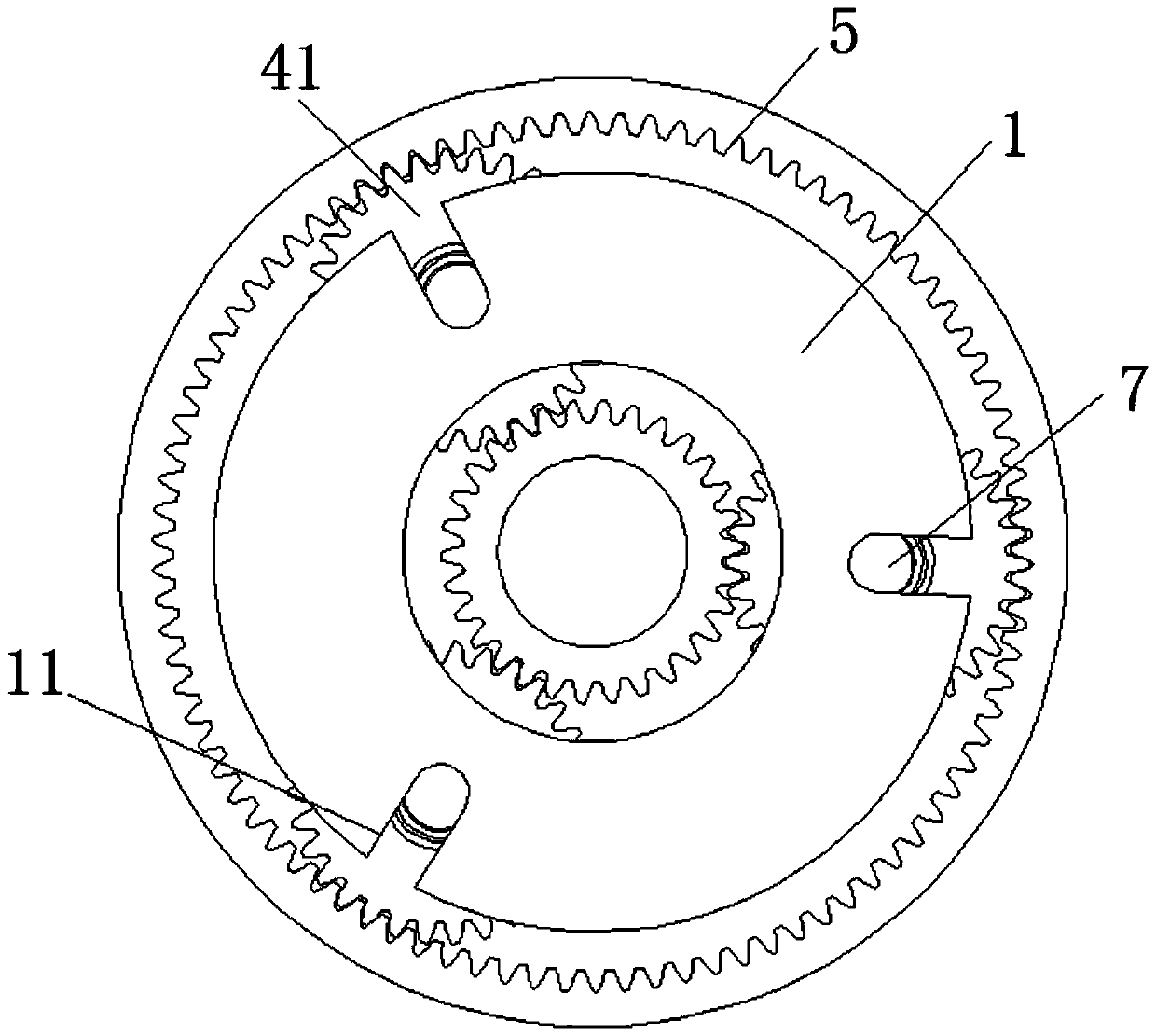

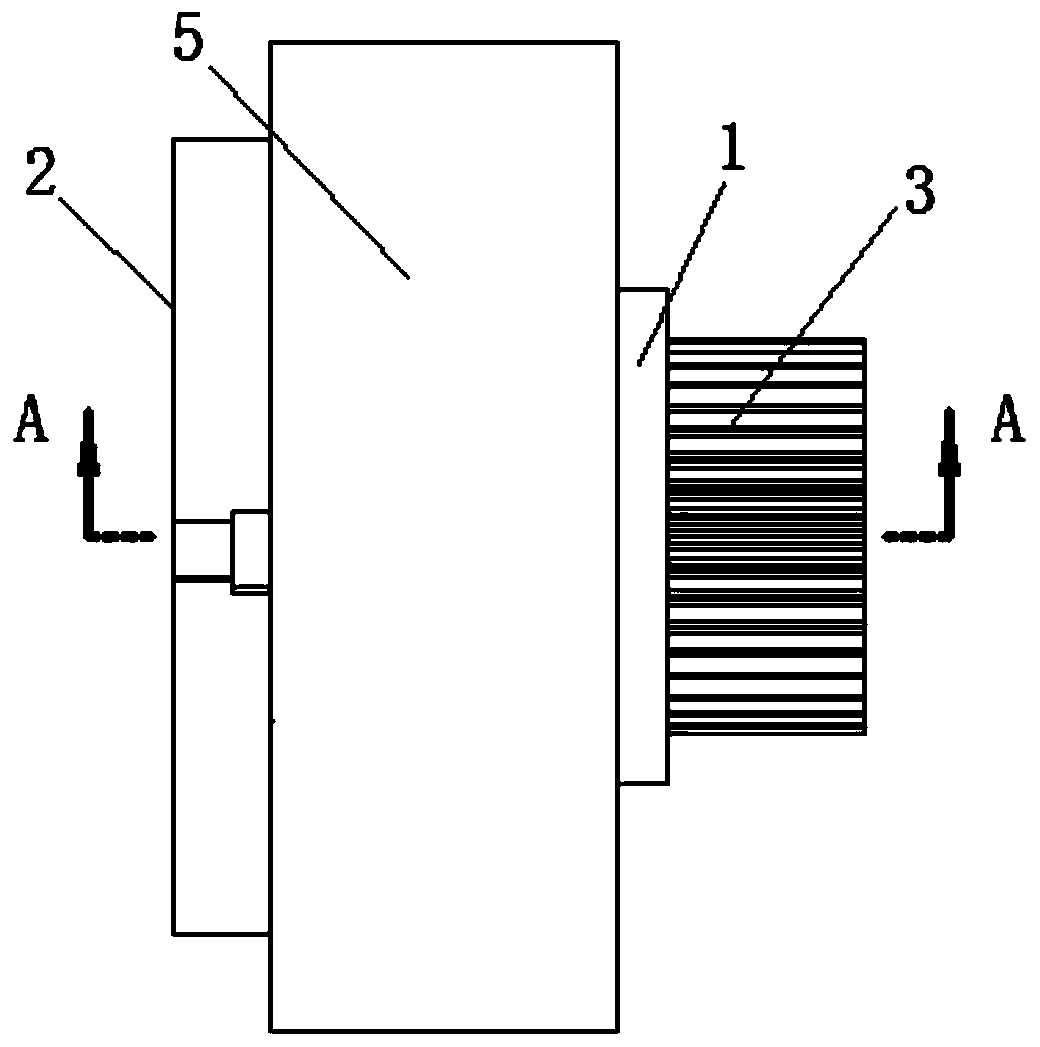

Floating planetary gear train structure for miniature precise planetary reducer

PendingCN110159710AUniform loadLimited axial movementGear vibration/noise dampingToothed gearingsLow speedReducer

The invention discloses a floating planetary gear train structure for a miniature precise planetary reducer. The floating planetary gear train structure comprises a planetary carrier, a high-speed sungear, a low-speed sun gear, a planetary gear set and an inner gear ring, wherein the high-speed sun gear is meshed with the planetary gear set, the inner gear ring is meshed with the planetary gear set, the planetary carrier is in a cage type structure, and the planetary gear set is arranged on the cage type planetary carrier in a floating mode to automatically adapt to the central distance and the matching clearance; the floating planetary gear train structure further comprises a gasket, and the two ends of the planetary gear set are correspondingly limited by the cage type planetary carrierand the gasket to limit the axial movement of the planetary gear set. The floating planetary gear train structure for the miniature precise planetary reducer is exquisite and compact in structure, aU-shaped stepped slot and an annular open slot are designed on the cage type planetary carrier, planetary gears are mounted on the U-shaped stepped slot in a rotating floating mode through pin shaftsand needle bearings so as to automatically adapt to the central distance and the matching clearance, so that the loads of all the planetary gears are uniform, the meshing transmission of the sun gear,the planetary gear and the inner gear ring is ensured, the operation is smooth, the noise and the temperature rise are reduced, the problems of blockage or unbalance are solved, and the reliability is high.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

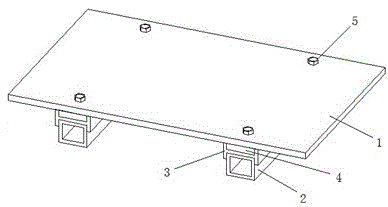

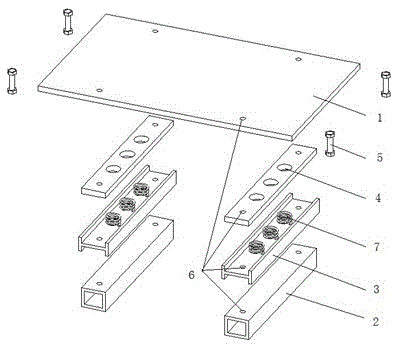

Shock-absorption base for transformer

InactiveCN105632696AImprove structural strengthImprove structural stabilityTransformers/reacts mounting/support/suspensionABSORPTION BASETransformer

The invention discloses a shock-absorption base for a transformer. The shock-absorption base comprises square tube steel, H-shaped steel and a shock-absorption rubber plate, wherein the square tube steel is arranged in a lower part groove in the H-shaped steel; the shock-absorption rubber plate is arranged in an upper part groove of the H-shaped steel; fixed holes are symmetrically formed in the two ends of a transformer bottom plate, the square tube steel, the H-shaped steel and the shock-absorption rubber plate respectively; and the transformer bottom plate, the square tube steel, the H-shaped steel and the shock-absorption rubber plate can be fixedly connected by inserting fixed bolts into the fixed holes in sequence; multiple mounting holes are formed in the shock-absorption rubber plate; and a shock-absorption spring is connected with the upper part groove, positioned under the mounting holes, of the H-shaped steel. According to the shock-absorption base, the square steel is adopted to replace the conventional channel steel, so that the structural strength and the stability of the base are improved; the H-shaped steel with the shock-absorption rubber plate is arranged above the square tube steel, and the shock-absorption spring is arranged in the shock-absorption rubber plate, so that effective shock absorption can be realized, and relatively high nose in the running process of the transformer is avoided.

Owner:高建锐

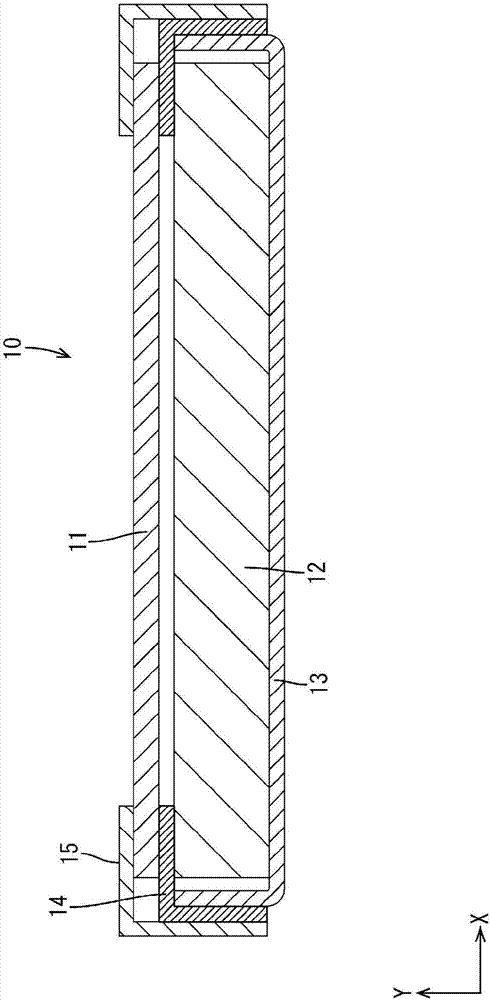

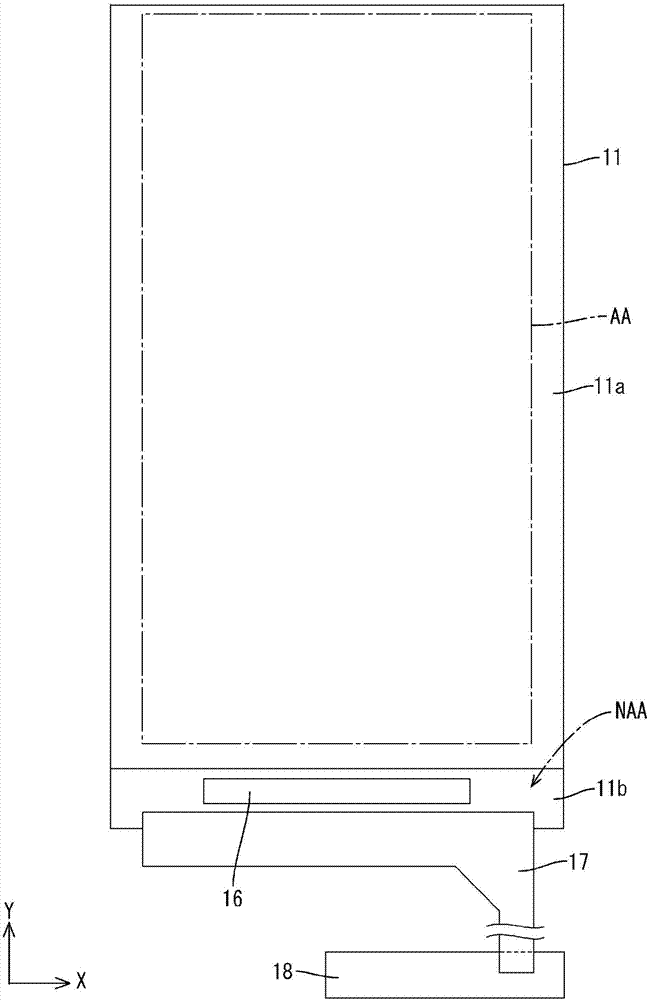

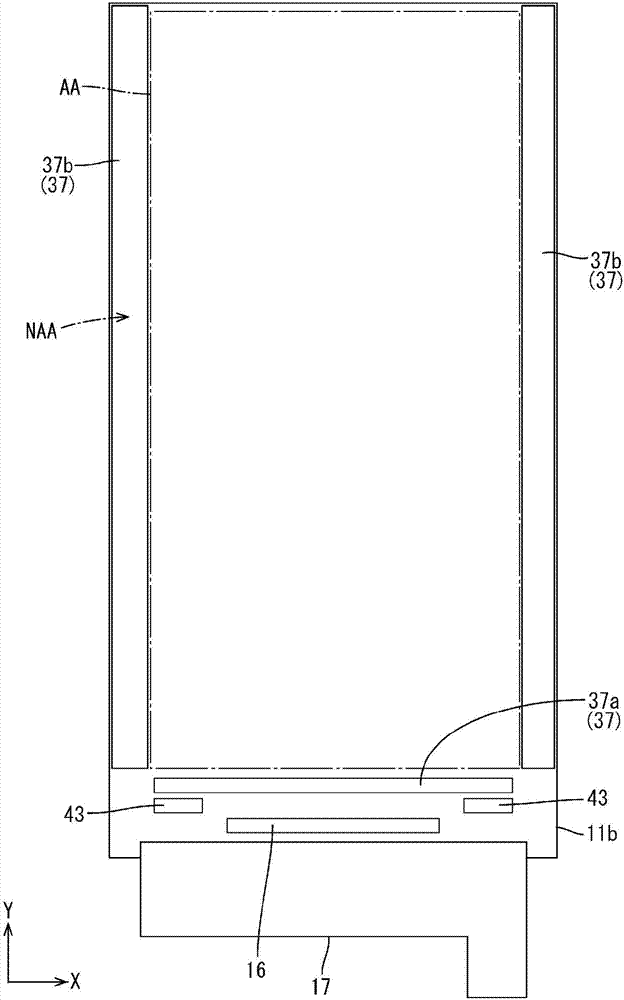

Display device fitted with position input function

InactiveCN107003769ALess prone to noiseFully ensure duringStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device 10 is provided with a TFT 19, a pixel electrode 20, a common electrode 23, an array substrate 11b, a CF substrate 11a, a detection electrode 38 provided on the CF substrate 11a, a drive electrode 39 provided on the CF substrate 11a, a driver 16 and a row control circuit unit 37b which are display drive units for supplying a scan signal Vscan and a data signal Vpix to the TFT 19 and driving the display, and a touch controller 48 for performing position detection control by supplying a drive signal Vdri to the drive electrode 39 and detecting a position detection signal Vdet outputted from the detection electrode 38, the touch controller 48 supplying the drive signal Vdri to the drive electrode 39 and driving the drive electrode 39 in at least a scanning write period in which the scan signal Vscan is supplied to the TFT 19 by the row control circuit unit 37b that is the display drive unit and the TFT 19 is driven.

Owner:SHARP KK

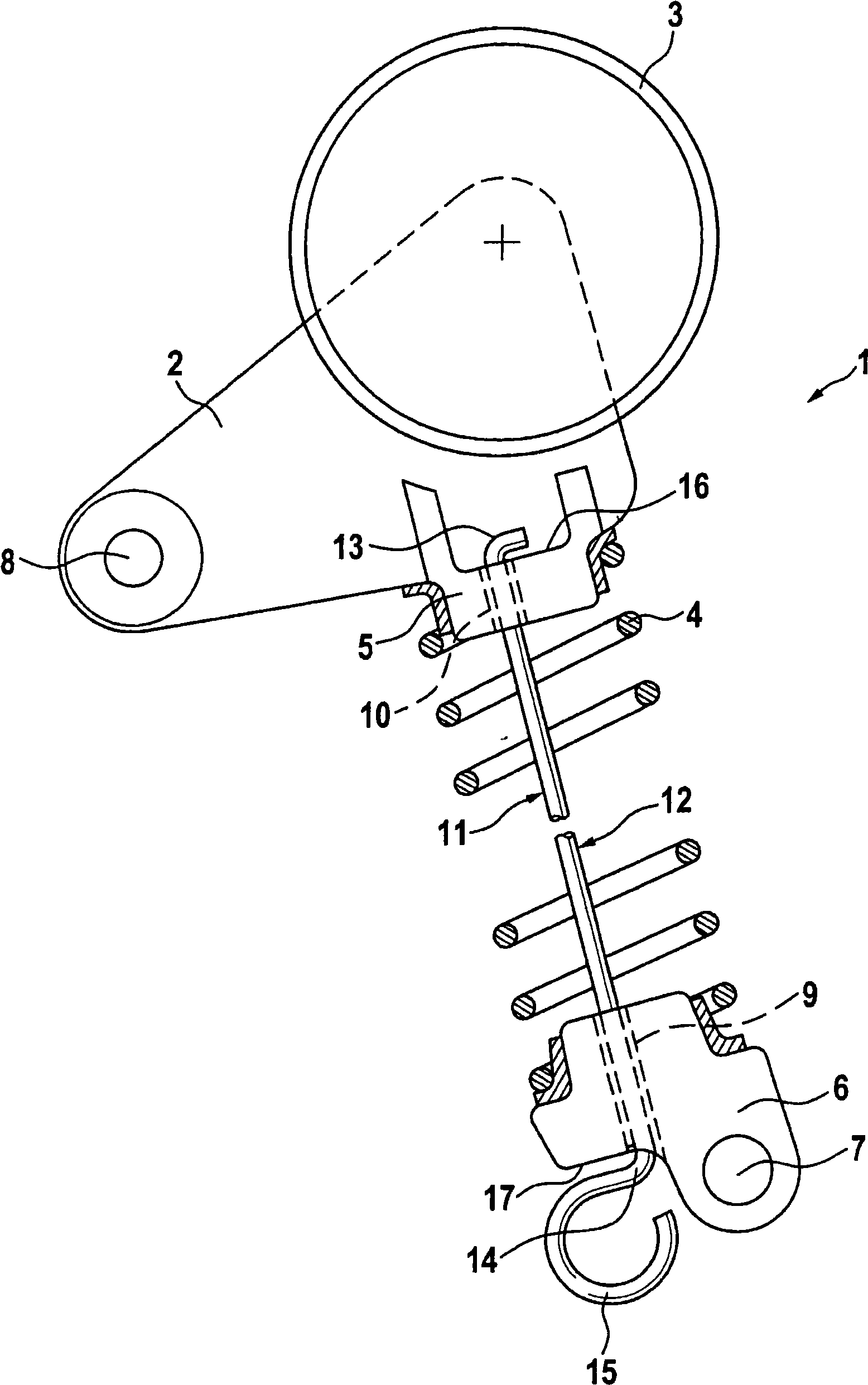

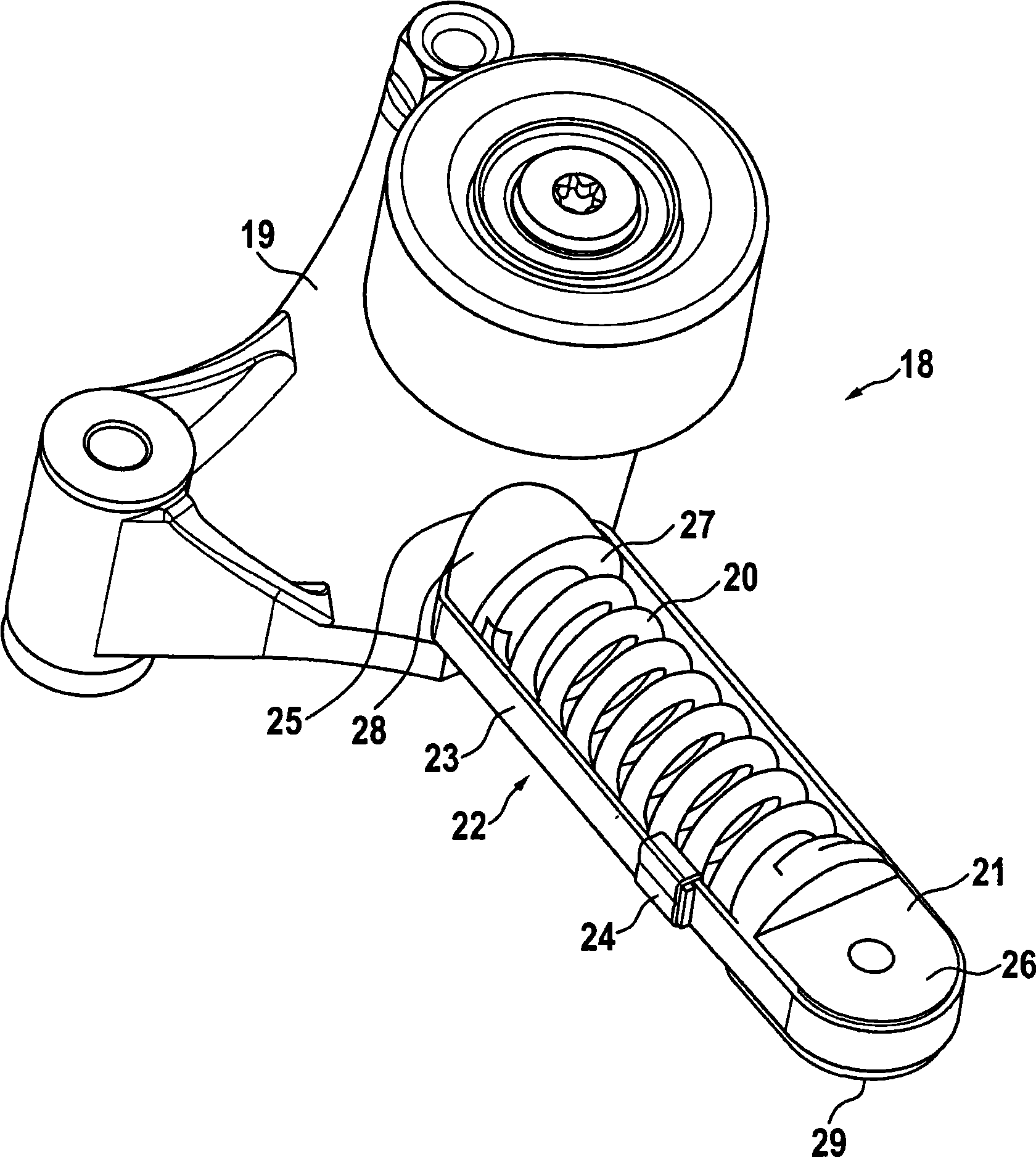

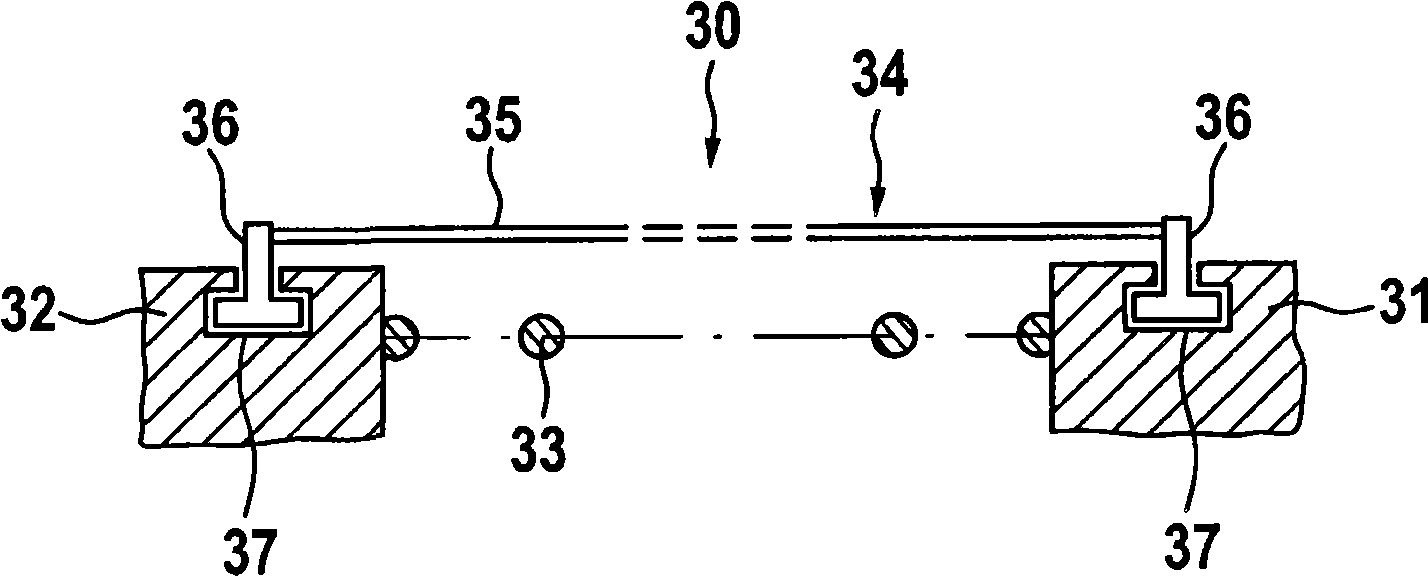

Tensioning device for a traction mechanism, in particular a belt or a chain

Owner:SCHAEFFLER TECH AG & CO KG

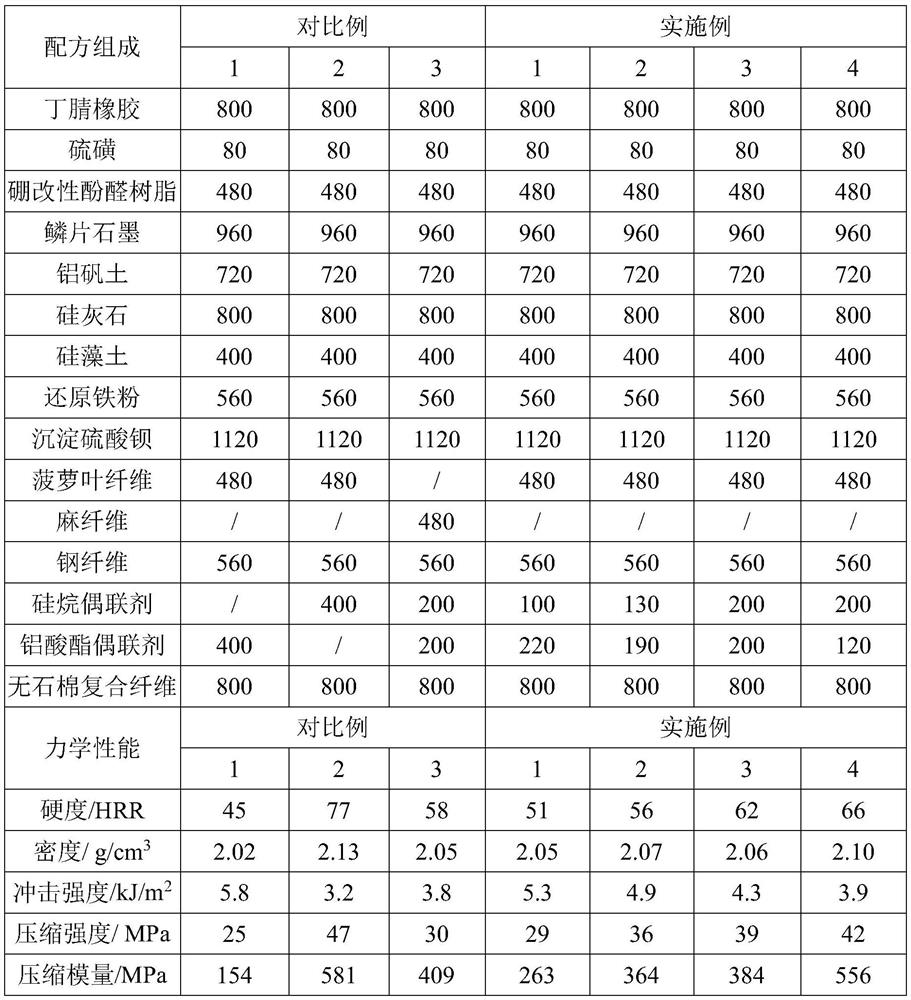

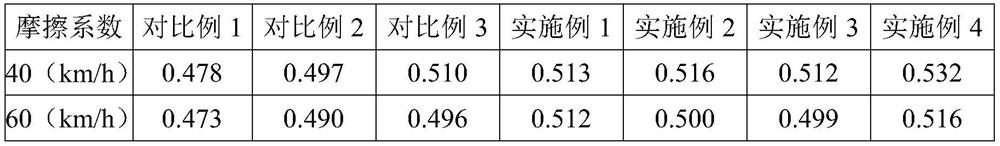

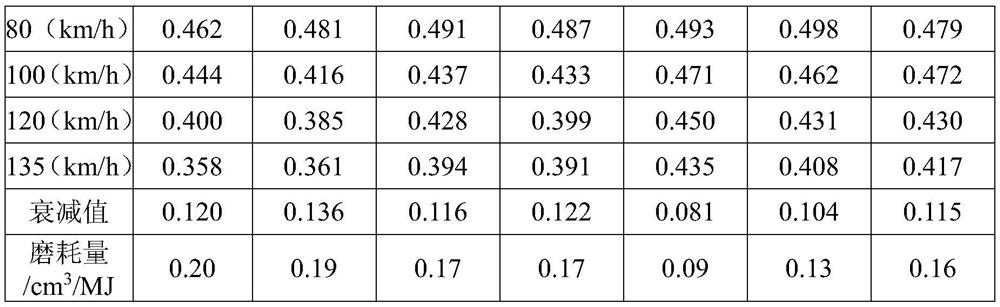

Synthetic friction material and preparation method and application thereof

ActiveCN113388173AImprove mechanical propertiesReduce coefficient of frictionNitrile rubberPhysical chemistry

The invention provides a synthetic friction material and a preparation method and application thereof. The synthetic friction material comprises the following components in percentage by mass: 8-10% of nitrile rubber, 0.9-3% of sulfur, 5-7% of boron modified phenolic resin, 10-14% of crystalline flake graphite, 8-10% of bauxite, 8-10% of wollastonite, 3-5% of diatomite, 6-7% of reduced iron powder, 12-15% of precipitated barium sulphate, 5-7% of pineapple leaf fibers, 6-8% of steel fibers, 2-4% of a coupling agent combination agent and 7-10% of inorganic mineral fibers. The sum of the mass percentages of all the components is 100%. The coupling agent combination agent comprises a silane coupling agent and an aluminate coupling agent. The invention further provides application of the synthetic friction material in synthetic friction materials for urban rail vehicles. The synthetic friction material provided by the invention has the advantages of environmental protection, high mechanical strength, low compression modulus, small dual wear, low abrasion and the like.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

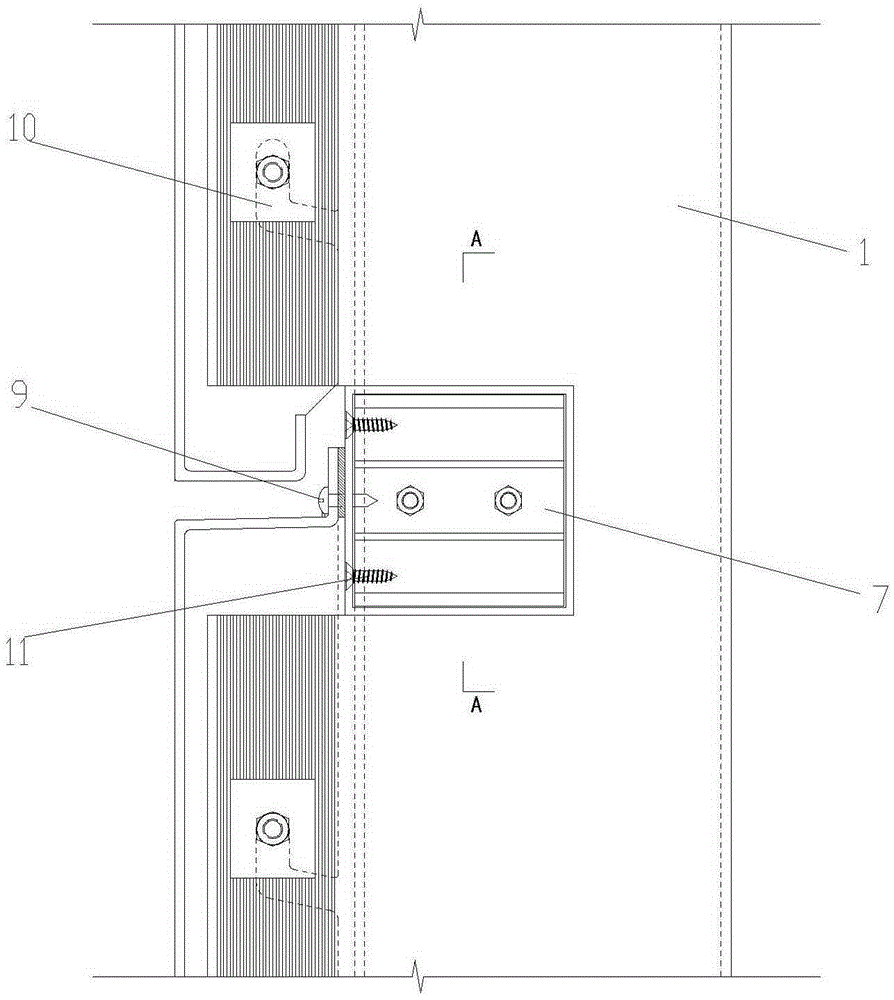

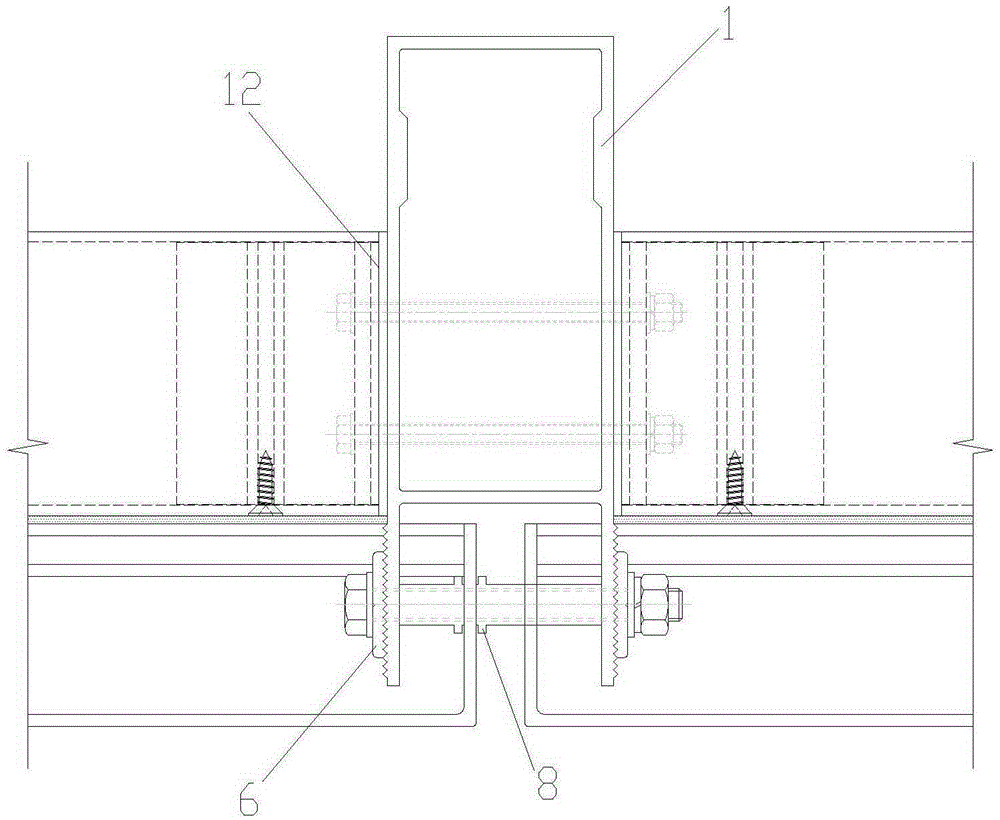

Open aluminum plate curtain wall

The invention discloses an open aluminum plate curtain wall which comprises two upper unit aluminum single plates, two lower unit aluminum single plates, an aluminum alloy stand column and two aluminum alloy cross beams. The vertical aluminum alloy stand column serves as a center shaft, and the two upper unit aluminum single plates on the upper side and the two lower unit aluminum single plates on the lower side are symmetrically laid to form an outer wall face. A stand column watching face for connecting the upper unit aluminum single plates with the lower unit aluminum single plates is arranged on one side face of the aluminum alloy stand column. A cross-shaped supporting body is formed by the aluminum alloy stand column and the aluminum alloy cross beams on the two sides of the aluminum alloy stand column. Multidirection aluminum alloy cross beam connecting pieces are further fixed in the aluminum alloy cross beams. The aluminum alloy stand column and the multidirection aluminum alloy cross beam connecting pieces are fixed through stainless steel bolts. The lower unit aluminum single plates are fixedly connected with the aluminum alloy cross beams through stainless steel self threading pins. The corresponding two upper unit aluminum single plates and the two lower unit aluminum single plates on the two sides of the aluminum alloy stand column are connected with the stand column watching face through stainless steel bolts. The surface of the stand column watching face is a sawtooth surface.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

High-impact environment-friendly V belt and manufacturing process thereof

The invention discloses a high-impact environment-friendly V belt and a manufacturing process thereof. A manufacturing raw material of the high-impact environment-friendly V belt is composed of canvas, raw glue, wrapping cloth, chemical raw materials, wire ropes, primer, cushioning glue and cloth glue. Aramid fiber framework wire ropes imported from Japan are adopted, during work running, instantlarge power can be borne, the rotating power is five times that of a common V belt, the strength is three times that of a common V belt, in the running process, extension and shrinkage are avoided, the belt is suitable for multi-wheel rotation, meanwhile, during pressing wheel engagement and disengagement, noise is not prone to happening, during running work, when the belt collides with foreign matter and stops working, the belt has the beneficial effects that the friction coefficient is reduced, impact force borne by the belt is reduced, the phenomenon that a motor is burnt out, and the beltis broken is avoided, during running work, glue powder is not prone to appearing in the work face, and the ground environment is protected.

Owner:广德天鹏实业有限公司

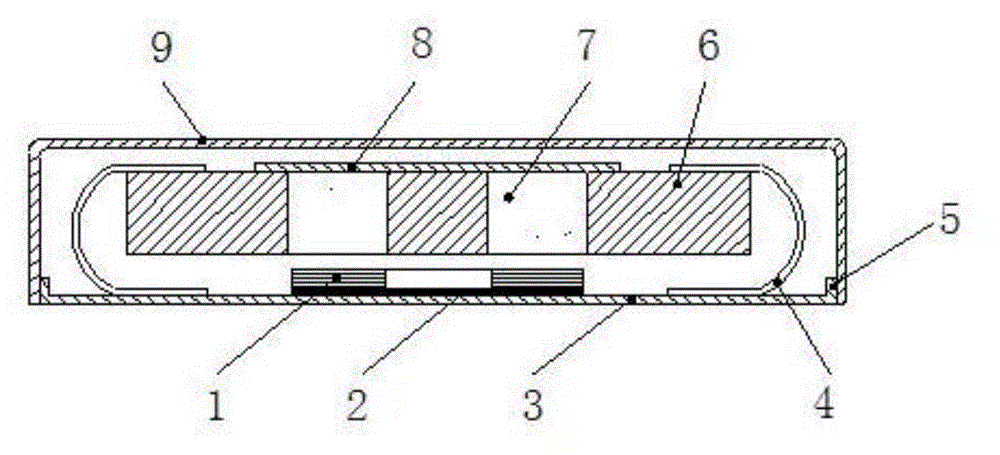

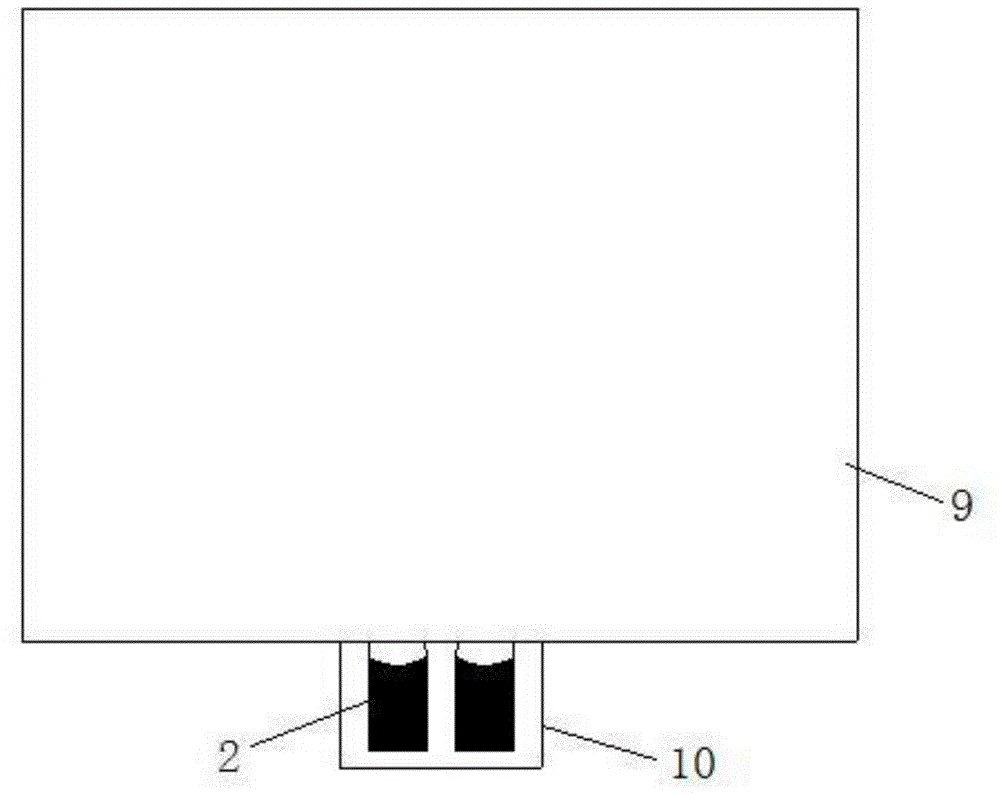

Horizontal vibration motor

ActiveCN104467340AShort response timeReduce the use of partsDynamo-electric machinesEngineeringMechanical engineering

The invention discloses a horizontal vibration motor, and aims to provide a horizontal vibration motor short in response time and long in service life. The horizontal vibration motor comprises a lower bracket assembly, a vibration assembly and an upper machine shell. Multiple coils are arranged on the lower bracket assembly, the vibration assembly comprises springs, a vibration hammer and multiple bars of magnetic steel installed on the vibration hammer. The springs are installed on the left side and the right side of the vibration hammer respectively. The vibration assembly is installed on the lower bracket assembly through the springs, the magnetic steel corresponds to the coils, and the upper machine shell is installed on the lower bracket assembly and covers the whole vibration assembly. The horizontal vibration motor has the advantages of being short in response time, having a few components, being simple in production technology, long in service life, free of abrasion and good in vibration effect and using effect, noise is not prone to occurring, and vibration feeling is relatively strong because the vibration hammer of the horizontal vibration motor is large.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

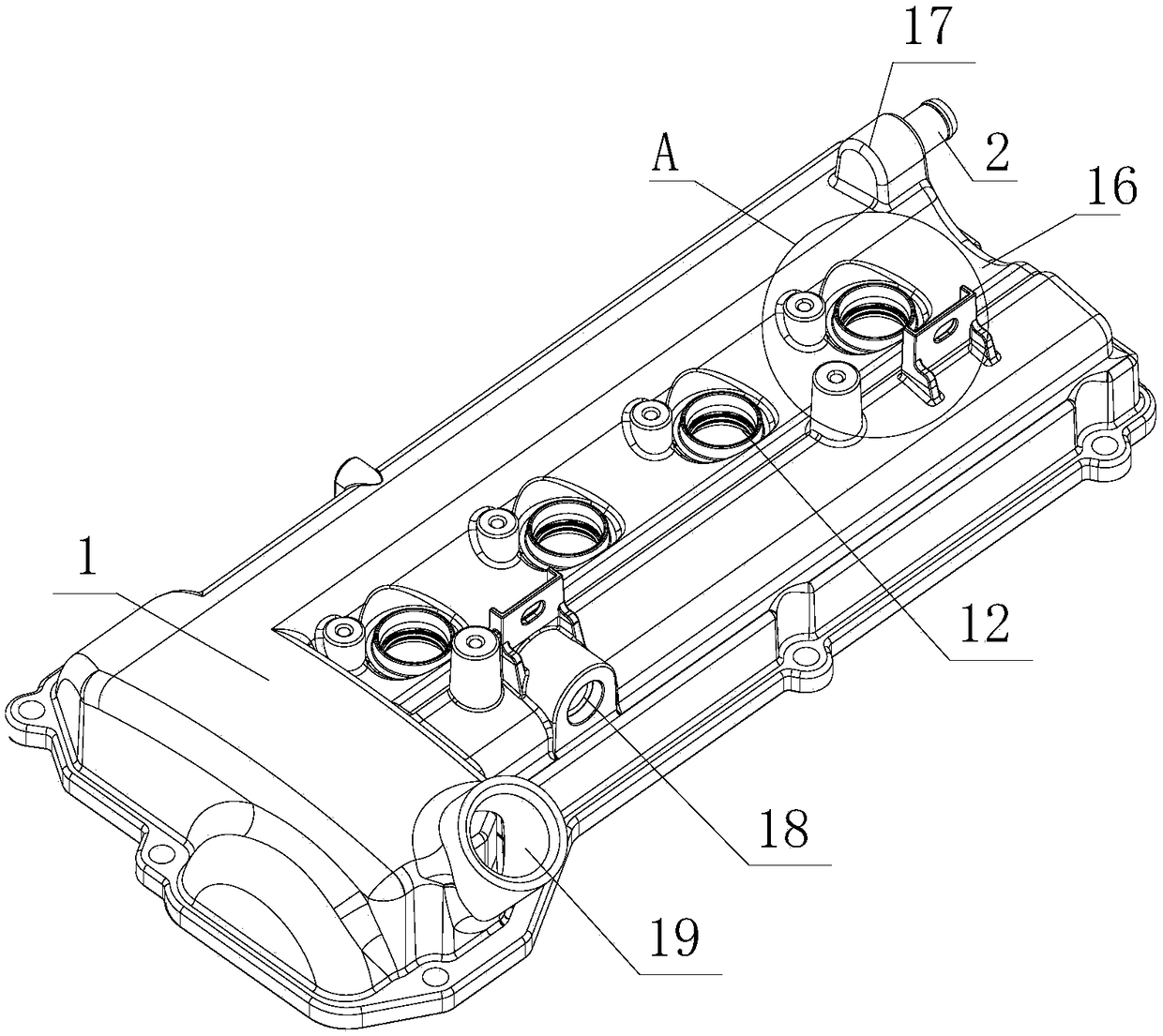

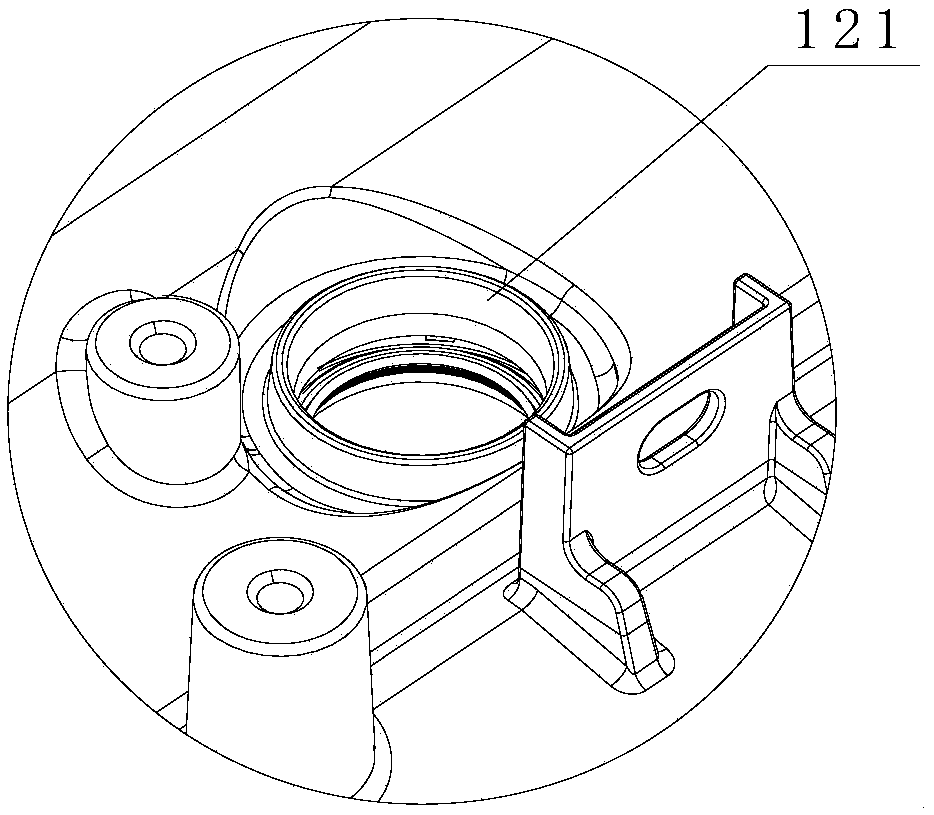

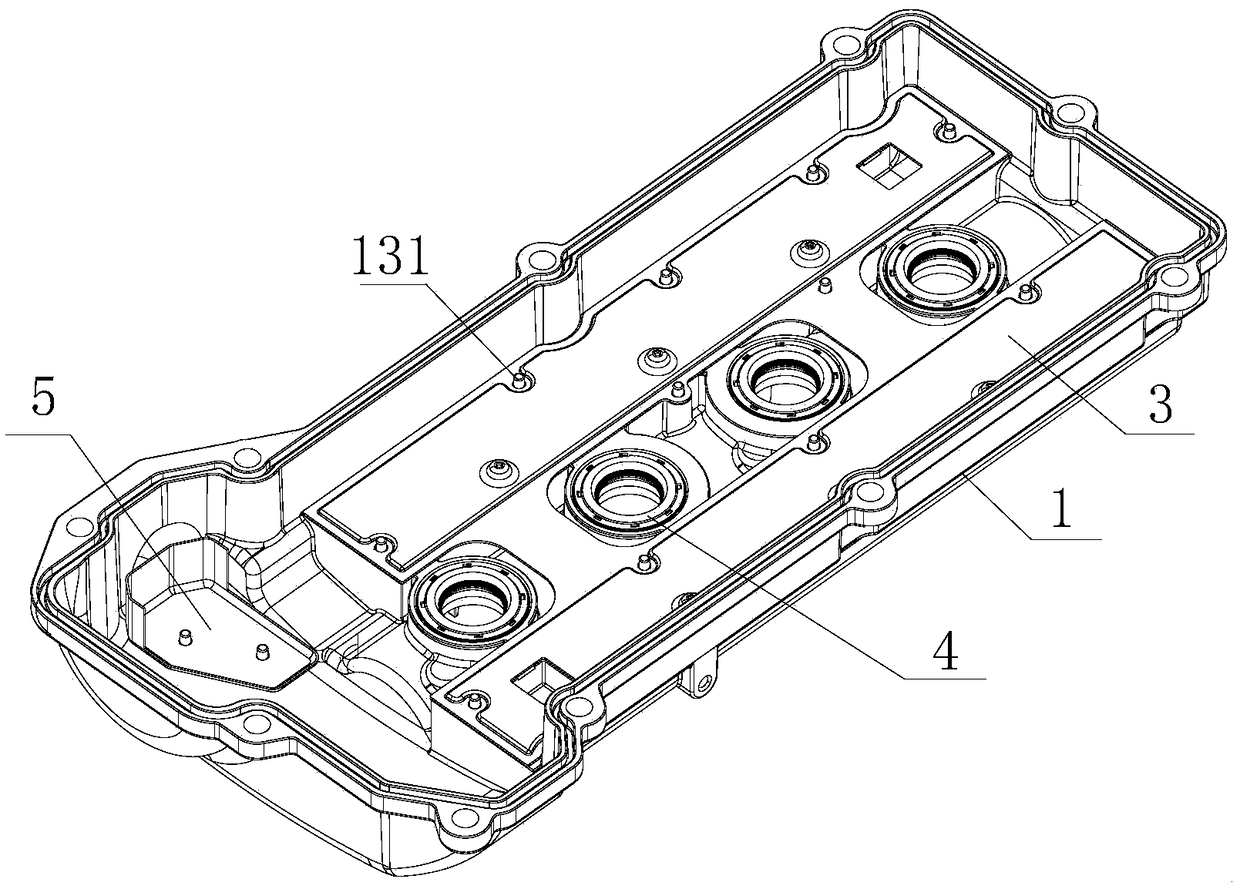

Low-noise oil-gas separation type cylinder head cover assembly

The invention discloses a low-noise oil-gas separation type cylinder head cover assembly. The low-noise oil-gas separation type cylinder head cover assembly comprises a cylinder head cover body provided with an inner cavity, a gas outlet pipe communicating an outer cover of the cylinder head cover body with the inner cavity, a labyrinth cover plate assembly arranged in the middle of the inner cavity, and an oil baffle plate arranged at one end of the inner cavity; the outer cover surface of the cylinder head cover body is provided with a gas outlet communicating with the inner cavity, a PVC valve hole and an oil filler cover hole; a downwards-concave water guiding groove is formed in the middle of the outer cover surface; a plurality of ignition coil mounting bases are arranged in the water guiding groove at intervals; the bottom surface, close to the oil filler cover hole, of the inner cavity is provided with an oil baffle plate mounting base; the inner cavity is internally provided with a first reinforcing rib connected with the ignition coil mounting bases; the end of the first reinforcing rib is provided with a second reinforcing rib connected with the first reinforcing rib, the bottom surface of the inner cavity and the side surface of the inner cavity; and the first reinforcing rib and the side wall of the inner cavity are provided with a plurality of sealing plate mounting bases. The cylinder head cover assembly has the function of flow guiding, liquid accumulated at the top of a cylinder head cover can be effectively discharged, the structural strength is high, theanti-vibration capability is good, the service life is long, and low-cost oil separation can be achieved.

Owner:鼎欣吉盛科技(浙江)有限公司

Method for determining the path length of a sample and validating the measurement obtained

ActiveUS8947668B2Less-prone to contaminationLess-prone to noiseColor/spectral properties measurementsCuvettePath length

A for traceably determining an unknown optical path length of a sample in an optical measuring device comprises the steps of: providing a drop analyzer connected to a standard spectrophotometer; providing a certified reference material contained in first and second closed high accuracy cuvettes; measuring absorbance of the certified reference material to obtain a first absorbance measurement for the first specified path length; measuring absorbance of the certified reference material for a second path length to obtain a second absorbance measurement; using a dropping device to drop a specified volume of the solvent on an optical surface so that the path length of the specified volume can be determined by reference to the first and second absorbance measurement; and using the dropping device to drop the same volume of sample as the specified volume of solvent on the optical measuring device.

Owner:STARNA SCI

Direct-current brushless motor structure for mobile phone

ActiveCN105406675AGuaranteed to workNo distractionDynamo-electric machinesBrushless motorsEngineering

The invention discloses a direct-current brushless motor structure for a mobile phone. The direct-current brushless motor structure comprises a rotor assembly, a stator assembly and an upper shell, wherein the rotor assembly comprises an eccentric weight, magnetic steel, an oil-retaining bearing and a yoke; the eccentric weight, the magnetic steel and the oil-retaining bearing are all arranged on the yoke; the stator assembly comprises a lower bracket, a coil, a revolving shaft and a driving chip with a Hall function; the coil, the revolving shaft and the driving chip with the Hall function are all arranged on the lower bracket; the rotor assembly is arranged on the stator assembly, and the oil-retaining bearing of the rotor assembly is matched with the revolving shaft of the stator assembly; the upper shell covers the rotor assembly and the stator assembly, and is connected with the lower bracket; and the lower bracket is provided with a plurality of through holes which are uniformly distributed. The direct-current brushless motor structure has the beneficial effects of capabilities of identifying the polarity of the magnetic steel and ensuring normal work of a motor, freeness from an electric brush, small size, less used components, simple production process, long service life, prevention of noise, and freeness from electronic interference.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

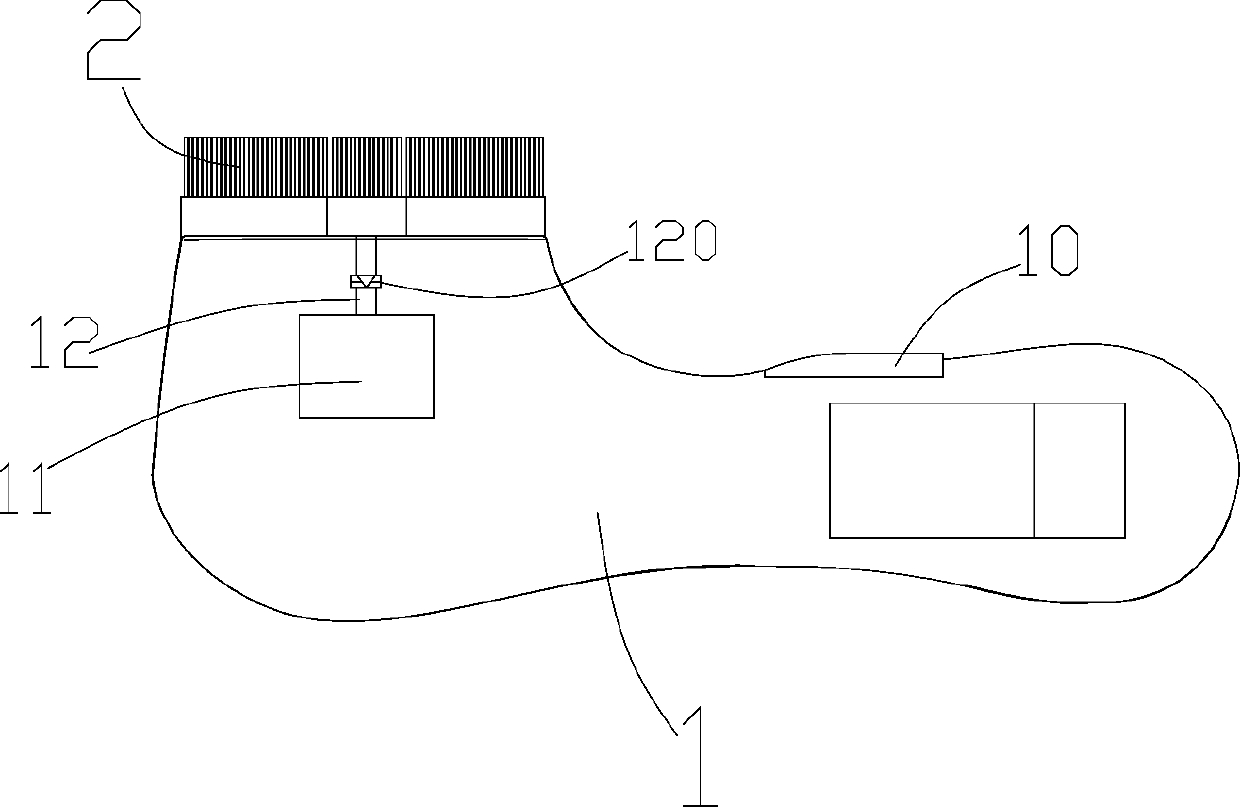

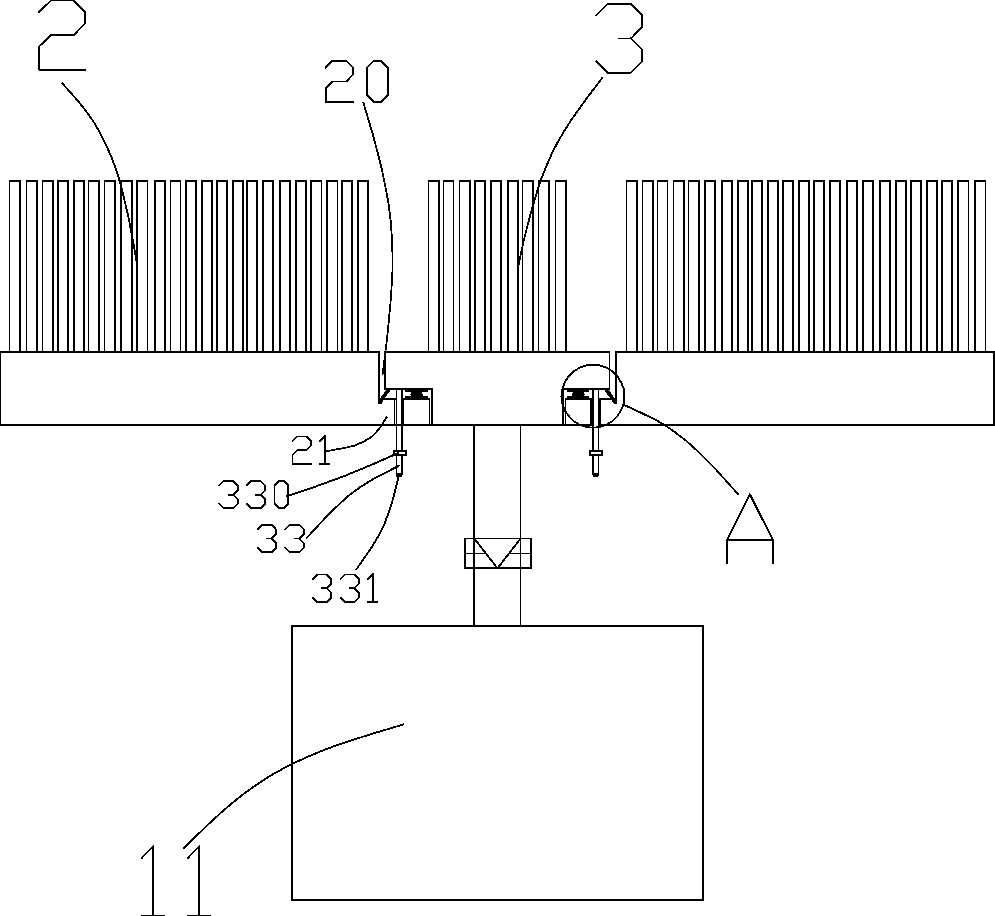

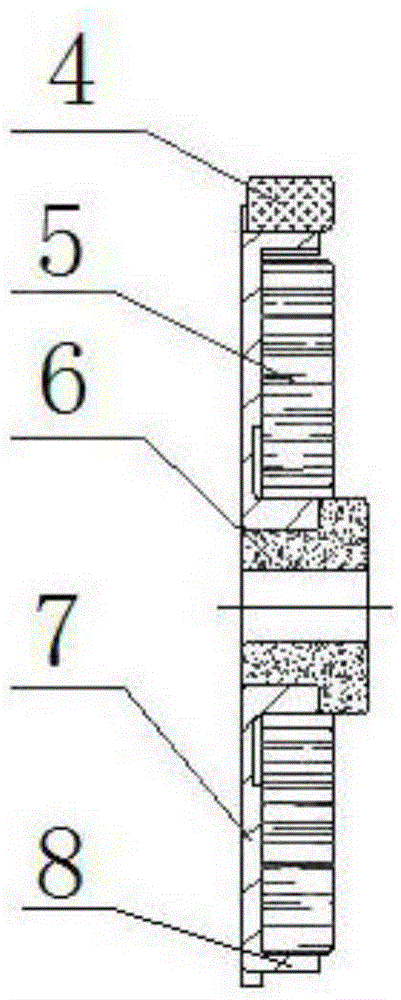

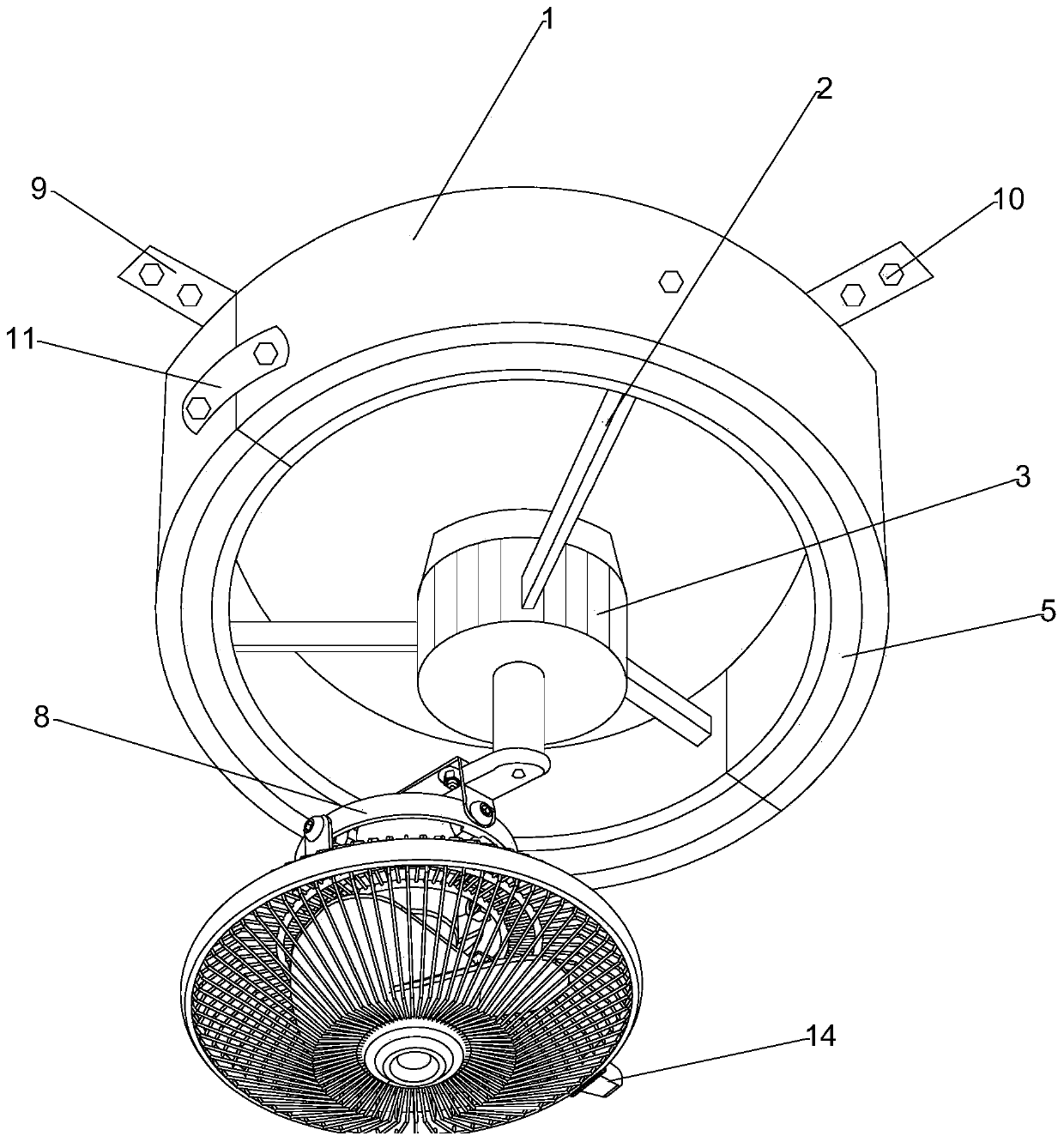

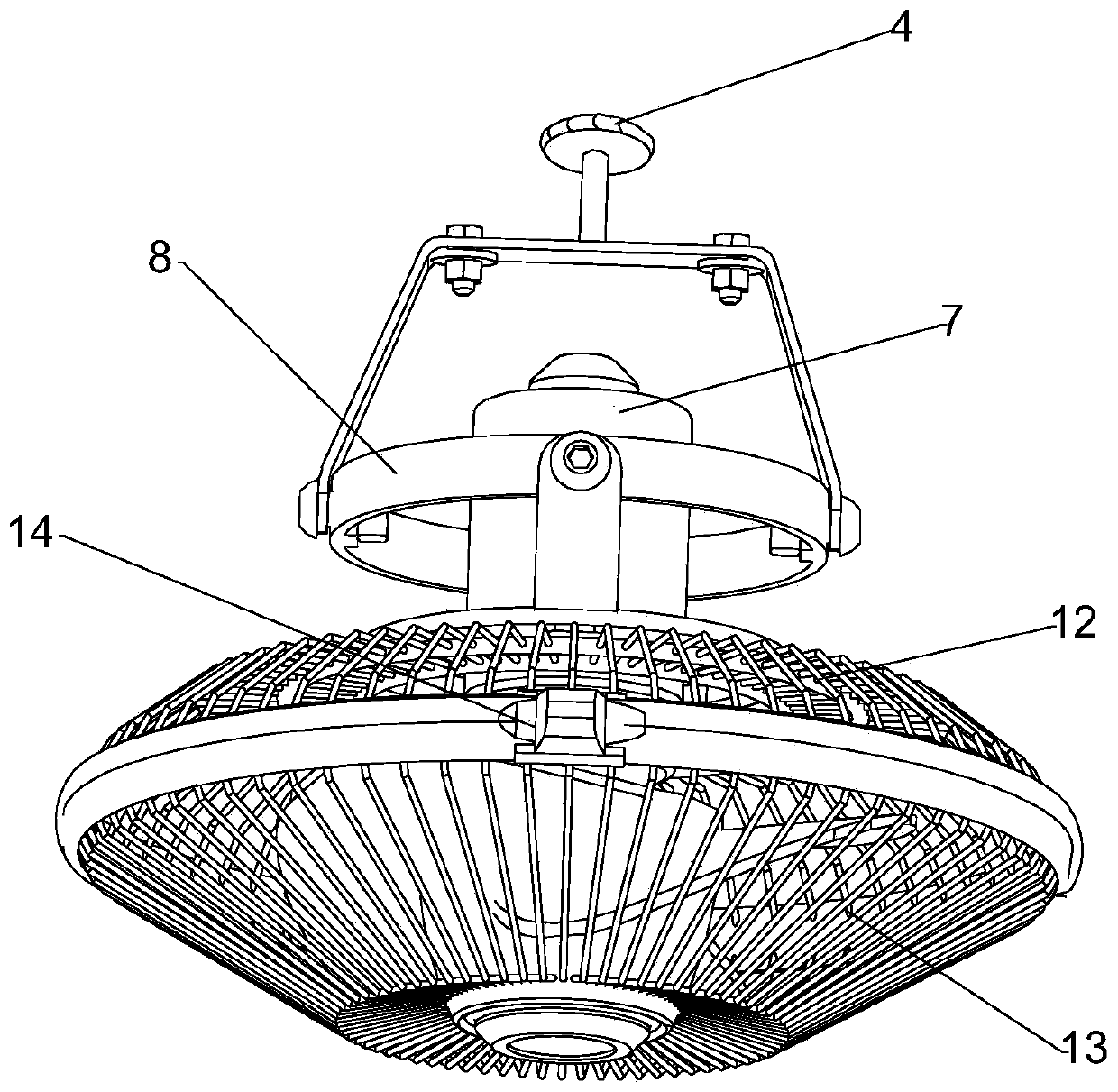

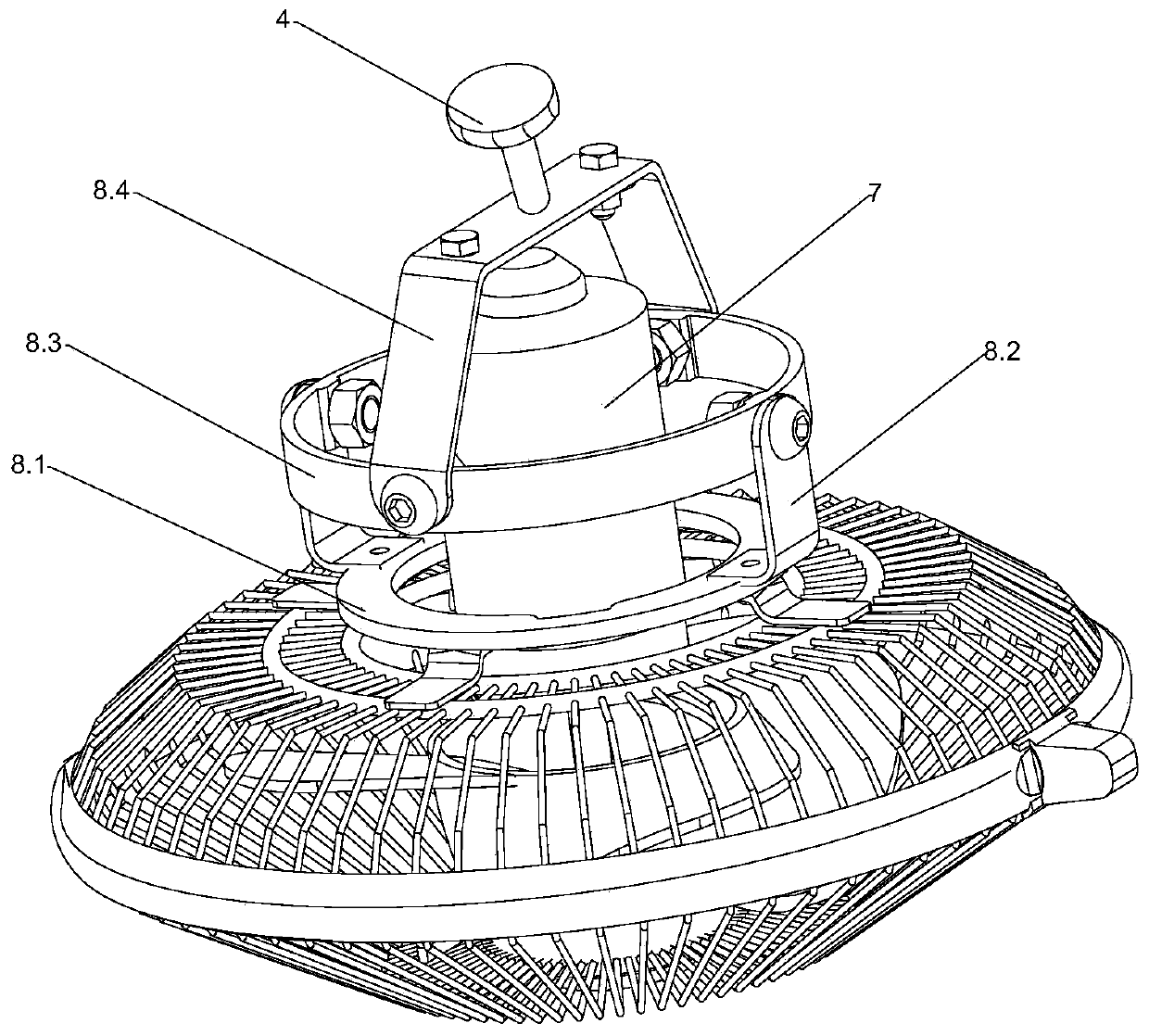

Multifunctional ceiling fan

InactiveCN109751268AExpand the blowing areaAvoid problems such as coldsPump componentsAir heatersCeiling fanAgricultural engineering

The invention relates to a multifunctional ceiling fan. The multifunctional ceiling fan is characterized in that the ceiling fan comprises a fan body, a track frame, a fixing frame and a track motor,a roller is arranged at the upper end of the fan body, a slide rail is arranged at the lower end of the track frame, the roller is connected into the slide rail in a clamping mode, the track motor isfixedly connected to the track frame through the fixing frame, and the track motor is fixedly connected to the fan body; and the fan body comprises a fan blade, a rotating motor and a fan body frame,the fan blade is made of two layers of metal plates, an electric heating wire is arranged between the two layers of metal plates, the rotating motor is fixedly connected to the upper end of the fan blade, the rotating motor is fixedly connected to the fan body frame, and the roller is fixedly connected to the upper end of the fan body frame. The cover range of wind blowing by the ceiling fan is wide, every area in a room be blown, excessive concentration of the ceiling fan blowing area is avoided, and heat can be provided for the room in winter.

Owner:林圣原

Hard disk destroying device for ensuring data security

InactiveCN111195648ACompletely destroyedSimple organizationSolid waste disposalGrain treatmentsEngineeringMachine

The invention discloses a hard disk destroying device for ensuring data security. The hard disk destroying device for ensuring the data security comprises a machine body and a power cavity arranged inthe machine body, wherein a power device is arranged in the power cavity, a grinding cavity is arranged in the machine body, a grinding device is arranged in the grinding cavity, a control installingcavity is arranged in the machine body, and a control device is arranged in the control installing cavity. The hard disk destroying device is simple in mechanism and easy and convenient to use, grinding, smashing and demagnetization of a hard disk are achieved through mechanical control, the hard disk is destroyed thoroughly, and meanwhile larger noise does not easily generated.

Owner:SHENZHEN BENDENG COMP CO LTD

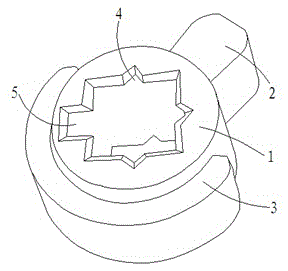

Novel two-sided dial wheel

The invention discloses a novel two-sided dial wheel. The novel two-sided dial wheel comprises a dial wheel body, a stirring protrusion fixedly arranged on one side of the outer circumference of the dial wheel body, and a circular-arc-shaped driving protrusion fixedly arranged on the other side of the outer circumference of the dial wheel body. A toothed groove and a key groove communicating with the toothed groove are formed in the middle of the dial wheel body. The toothed groove is formed in the middle of the dial wheel body for replacing an original shaft hole, so that vibration and noise caused by loosening of a sliding component are not liable to occur, and adhering and damage can be prevented.

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

Fireproof antitheft door

InactiveCN104278925AAvoid deformationExtended service lifeBurglary protectionWar-like protectionMaterials scienceCement

The invention belongs to the field of doors and particularly relates to a fireproof antitheft door which comprises a metal panel layer and a door core layer. The door core layer is provided with a cement layer and a perlite fireproof layer which are sequentially arranged from inside to outside. An iron net layer is arranged between the cement layer and the perlite fireproof layer. The thickness of the cement layer is equal to the thickness of the perlite fireproof layer. As the metal panel layer is filled with the cement layer and the perlite fireproof layer, a door body does not crack or deform easily when affected by external force, the service life of the door is prolonged, and criminal elements can be effectively prevented from breaking into houses.

Owner:HUZHOU TIEFO REFRACTORIES

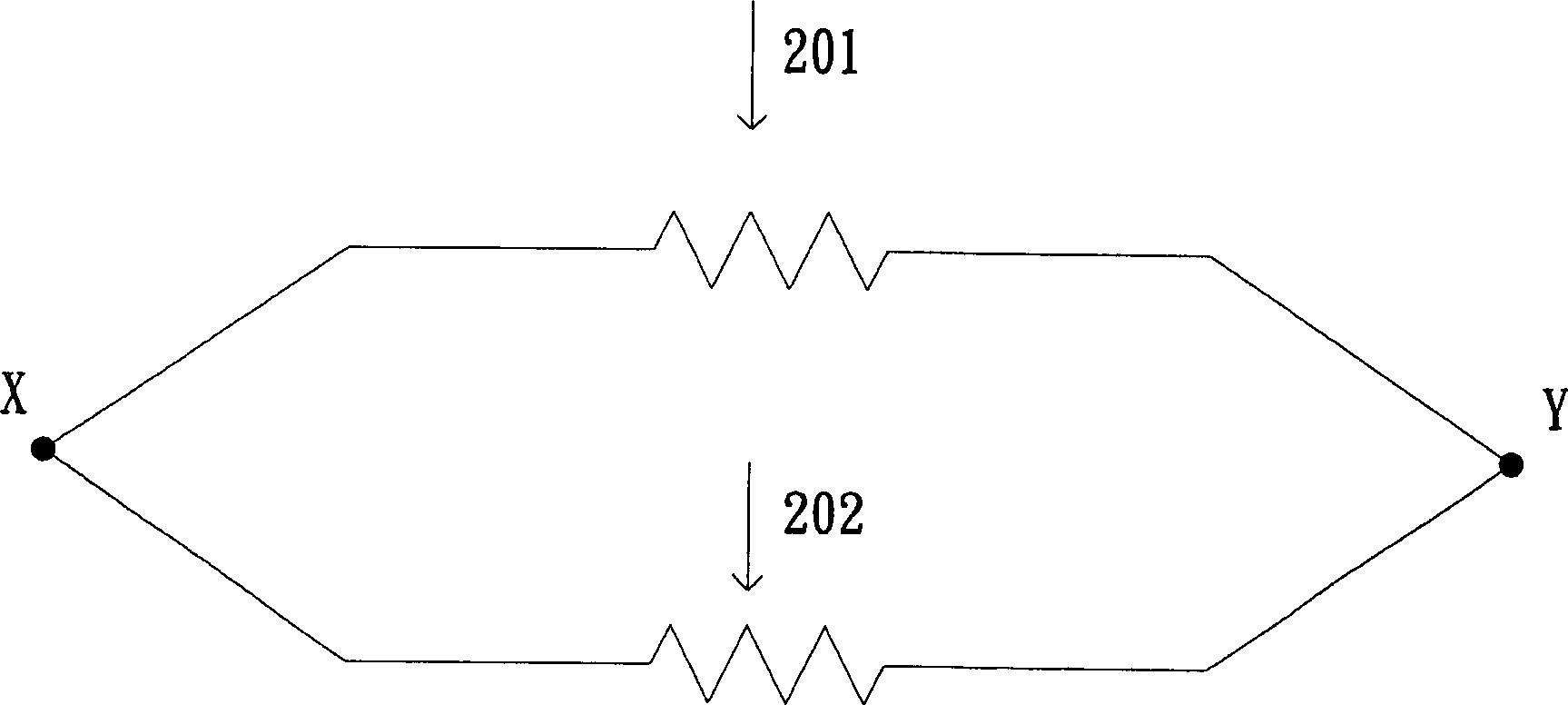

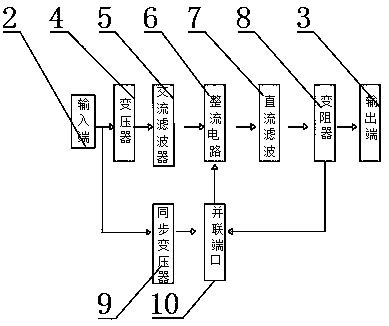

Rectifier having high voltage class

InactiveCN110112936AReduce magnetizationReduce consumptionAc-dc conversion without reversalCooling/ventilation/heating modificationsCapacitanceTransformer

The invention provides a rectifier having a high voltage class. The rectifier comprises a device body, wherein two ends of the device body are provided with an input end and an output end respectively; the inner bottom side end of the device body is provided with a transformer at a side close to the input end; one side of the transformer is provided with an AC filter; one side of the AC filter isprovided with a rectifier circuit; one side of the rectifier circuit is provided with a DC filter; one side of the DC filter is provided with a rheostat; one end of the input end of the internal circuit of the device body is connected with a synchronous transformer; the interior of the AC filter is composed of a capacitor and a transformer; and a thyristor is disposed in the DC filter. By means ofa spiral water-cooling pipeline, in actual operation, water circulation cooling can reduce the temperature inside the rectifier, prevents the over-high internal temperature from affecting the actualoperation process. Further, compared with the mode of a traditional rectifier having a high voltage class, the water cooling mode is less likely to produce noise and achieves a stable working condition.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com