Heat dissipating module of notebook computer

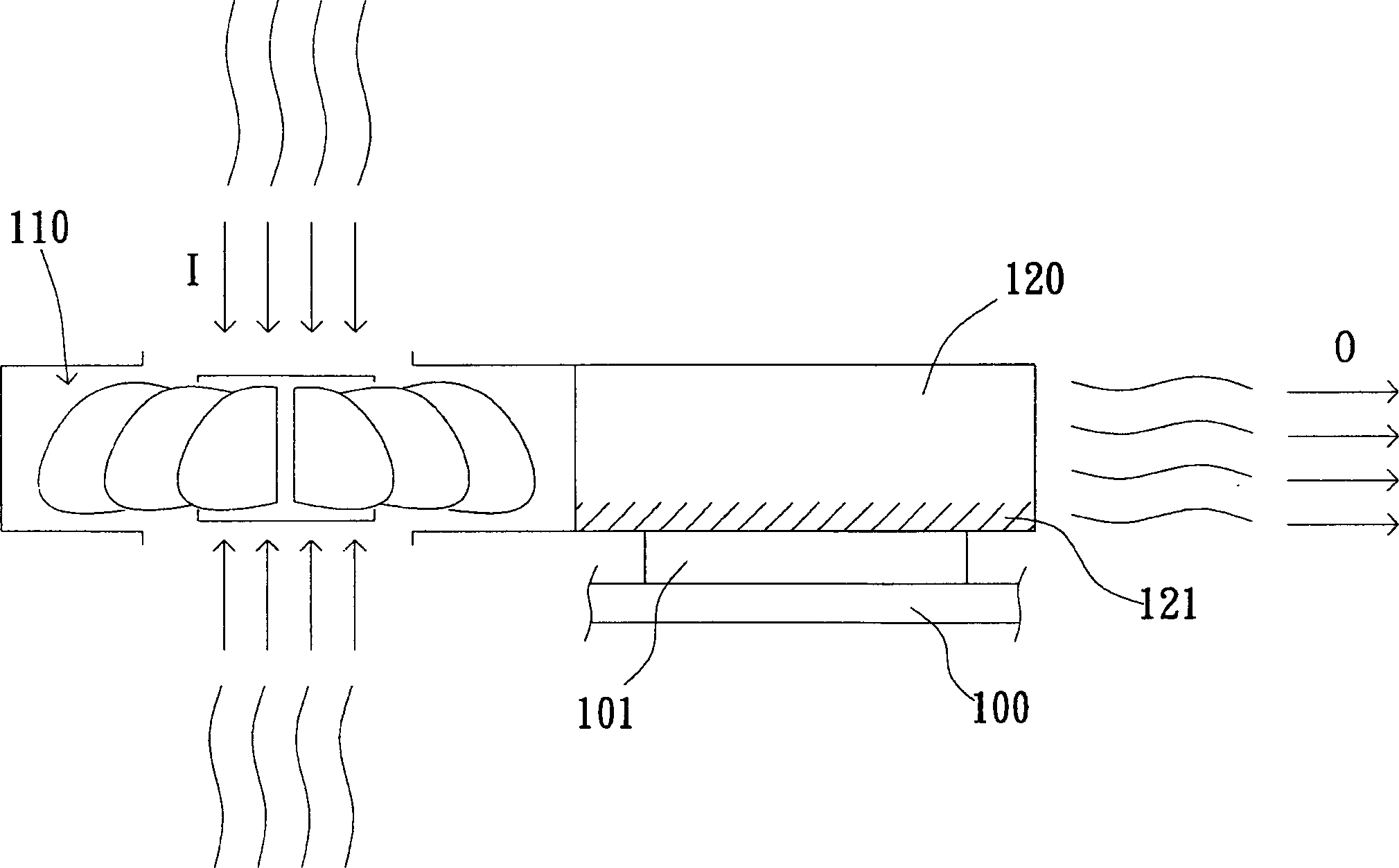

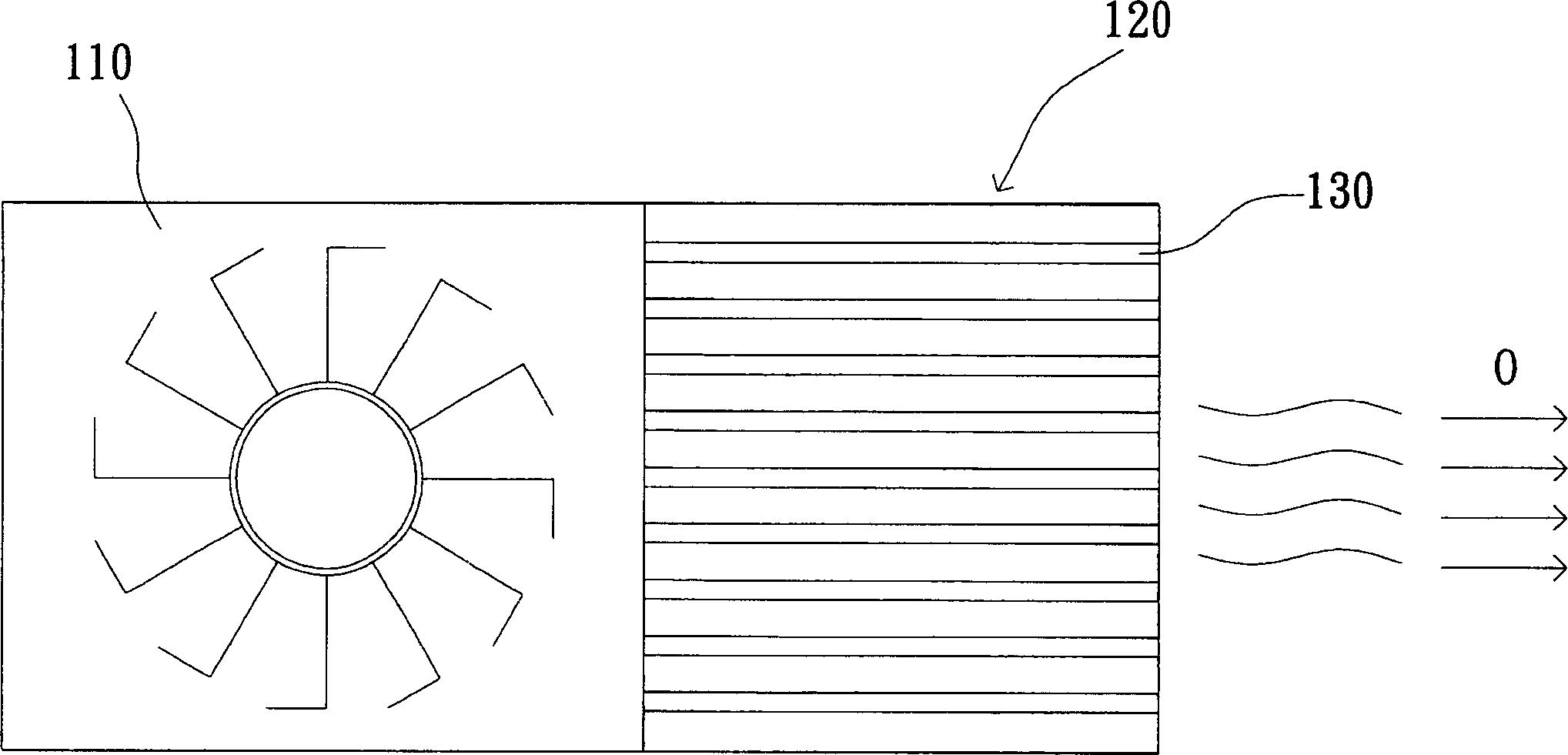

A notebook computer and heat dissipation module technology, applied in computing, instruments, electrical digital data processing, etc., can solve the problems of increasing the frictional resistance between the air and the fin 130, increasing the volume of the heat dissipation module, reducing the heat dissipation efficiency, etc., and achieving the difficult boundary effect , Improve heat dissipation efficiency, increase the effect of fin length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Then please refer to image 3 , which shows a top view of the heat dissipation module proposed according to Embodiment 1 of the present invention. As shown in the figure, the cooling module includes an inner fan 310 and two radiators 321, 322, and the radiators 321, 322 are connected by a heat pipe 340, and the heat pipe 340 is used as a heat conducting structure of the cooling module. The bottom surface of the heat sink 321 forms a contact surface (not shown) for contacting with the central processing unit 101 (or other types of chips) and exchanging heat; the fan 310 is configured in the notebook computer, and is different from a traditional fan in that There are two air outlets, and the radiators 321 and 322 are respectively arranged at the two air outlets of the fan 310 and coupled with the heat pipe 340 . Many fins 330 are arranged on the radiators 321 and 322 to allow air to pass through, and the fins 330 exchange heat with the passing air to dissipate the heat. ...

Embodiment 2

[0024] Next, please refer to FIG. 4 , which shows a top view of the heat dissipation module provided according to Embodiment 2 of the present invention. As shown in the figure, the cooling module includes a fan 410 and three radiators 421, 422, 423, and the radiators 421, 422, 423 are connected by a heat pipe 440, and the heat pipe 440 is used as a heat conducting structure of the cooling module. The bottom surface of the heat sink 421 forms a contact surface (not shown) for contacting with the central processing unit 101 (or other types of chips) and exchanging heat; the fan 410 is configured in the notebook computer, and is different from a traditional fan in that There are three air outlets, and the radiators 421 , 422 , 423 are respectively arranged at the three air outlets of the fan 410 and coupled with the heat pipe 440 . Many fins 430 are arranged on the radiators 421, 422, 423 to allow air to pass through, and the fins 430 exchange heat with the passing air to dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com