Rectifier having high voltage class

A rectifier and high-voltage technology, applied in the field of rectifiers, can solve the problems of low material utilization, low voltage stabilization accuracy, and increased manufacturing costs, and achieve the effects of avoiding magnetization, stable working conditions, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

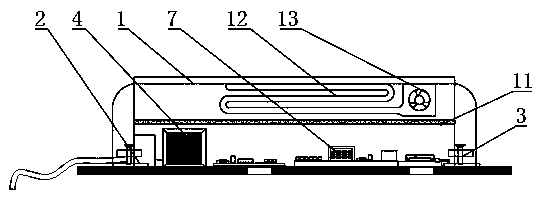

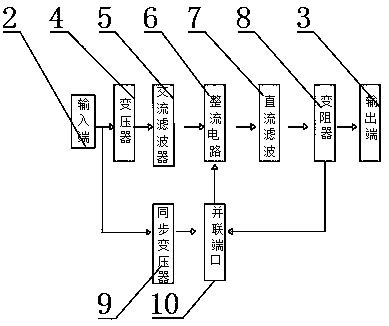

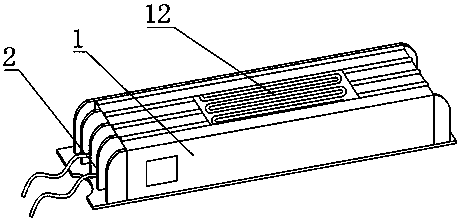

[0029] like Figure 1-6 As shown, the present invention provides a high-voltage level rectifier, including a device body 1, the two ends of the device body 1 are respectively provided with an input end 2 and an output end 3, and the inner bottom side of the device body 1 is close to the input end 2. A transformer 4 is installed on one side, an AC filter 5 is provided on one side of the transformer 4, a rectification circuit 6 is provided on one side of the AC filter 5, and a DC filter 7 is provided on one side of the rectification circuit 6. , one side of the DC filter 7 is provided with a rheostat 8, one end of the input terminal 2 in the internal circuit of the device main body 1 is connected to the synchronous transformer 9, and the other end of the rheostat 8 is connected to the rectifier circuit 6 through a parallel port 10 , an interlayer 11 is added at the inner middle position of the main body 1 of the device, and a water-cooled pipe 12 is arranged on the upper side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com