Low-noise modular joint of cooperative robot

A modular joint and robot technology, applied in the field of robots, can solve problems such as scratches and joint noise, and achieve the effect of less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

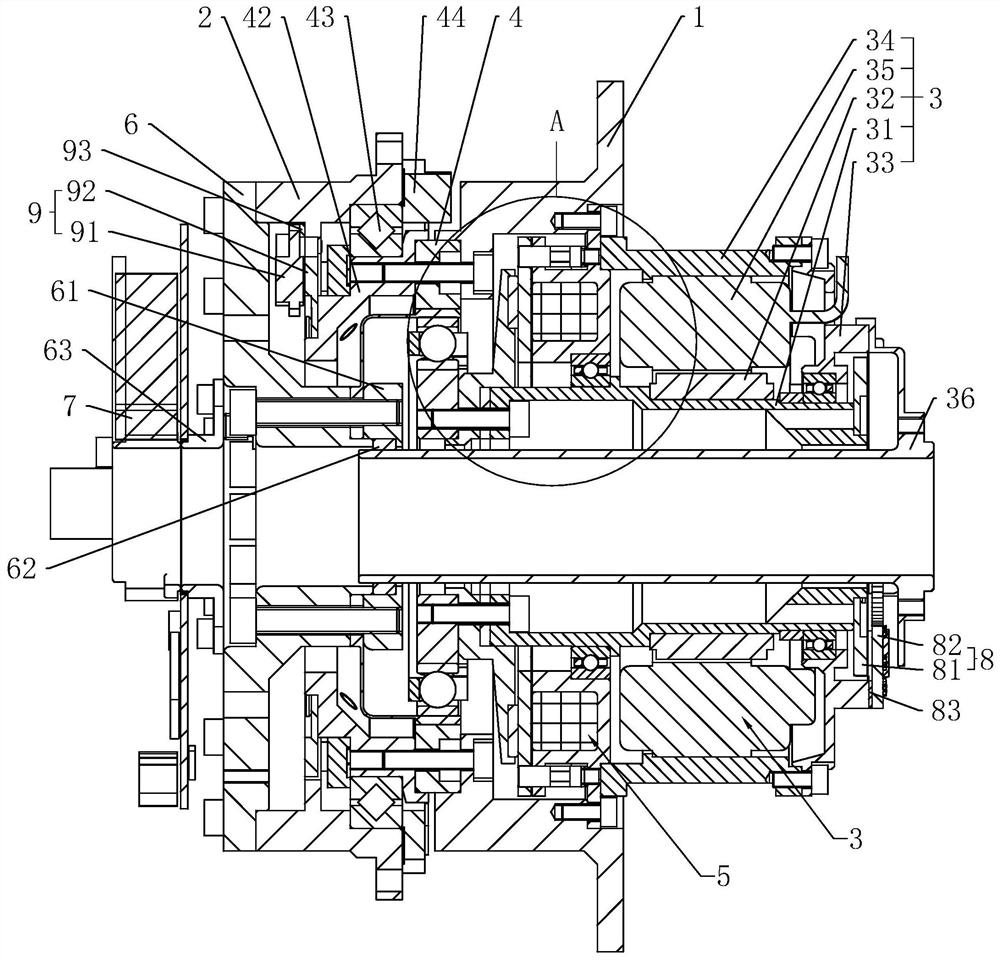

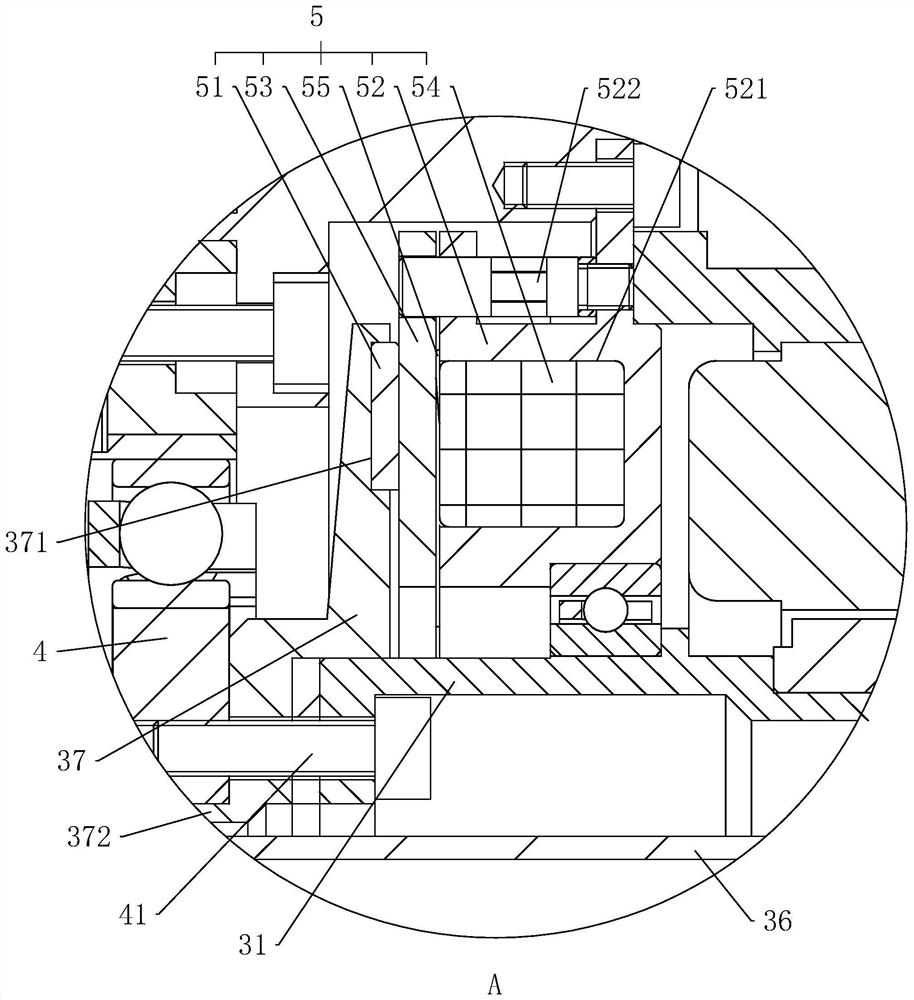

[0040] A low-noise collaborative robot modular joint disclosed by the present invention prevents scratches between the friction plate 51 and the braking member 53 during the normal rotation of the joint, making it difficult to generate noise during the working process of the joint. Such as figure 1 As shown, it includes an inner ring shell 1, an outer ring shell 2 that rotates relative to the inner ring shell 1, a drive mechanism 3 connected to the inner ring shell 1, a harmonic reducer 4 that drives the outer ring shell 2 to rotate, and limits the outer ring The braking mechanism 5 for the rotation of the housing 2.

[0041] Such as figure 1 As shown, the driving mechanism 3 includes a motor shaft 31, a motor rotor 32 coaxially bonded to the motor shaft 31, a motor end cover 33 coaxially sleeved on the motor shaft 31, and a motor housing fixed to the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com