Organic synthesis friction body, brake pad and preparation method of organic synthesis friction body and brake pad

An organic synthesis, brake pad technology, applied in friction linings, mechanical equipment, gear shifting mechanisms, etc., can solve problems such as low thermal conductivity, braking distance deviation, abnormal wear of brake pads, and achieve uniform distribution and strength. Enhanced, less prone to abnormal wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An embodiment of the present invention provides an organic synthetic friction body, including: liquid latex, nitrile rubber powder, silicone modified phenolic resin, rubber accelerator, copper fiber, steel fiber, mineral fiber, carbon fiber, metal filler and inorganic filler.

[0048] The above-mentioned organic synthetic friction body is a polymer ternary composite material, which is composed of binder, reinforcing fiber and filler. Among them, the binder can bond other components together to form a whole, and transmit and balance the load. The composition of the binder includes liquid latex, nitrile rubber powder, silicone modified phenolic resin and rubber accelerator.

[0049] Specifically, the liquid latex has high conjunctival strength, cohesive force and abrasion resistance, good stability and fluidity, and the liquid latex has good compatibility with fillers and good storage stability. Nitrile rubber powder has the advantages of good dispersibility, easy operat...

Embodiment 2

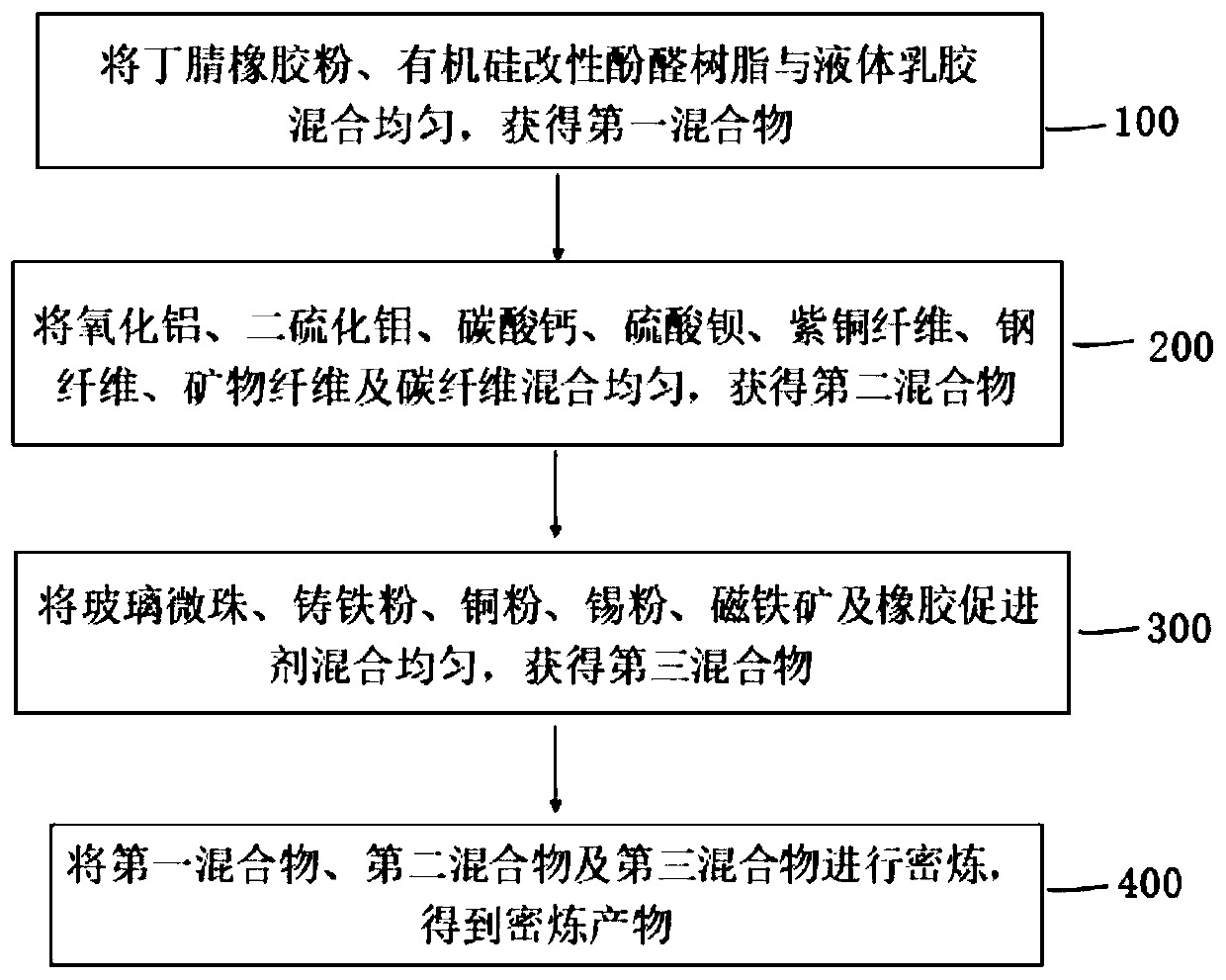

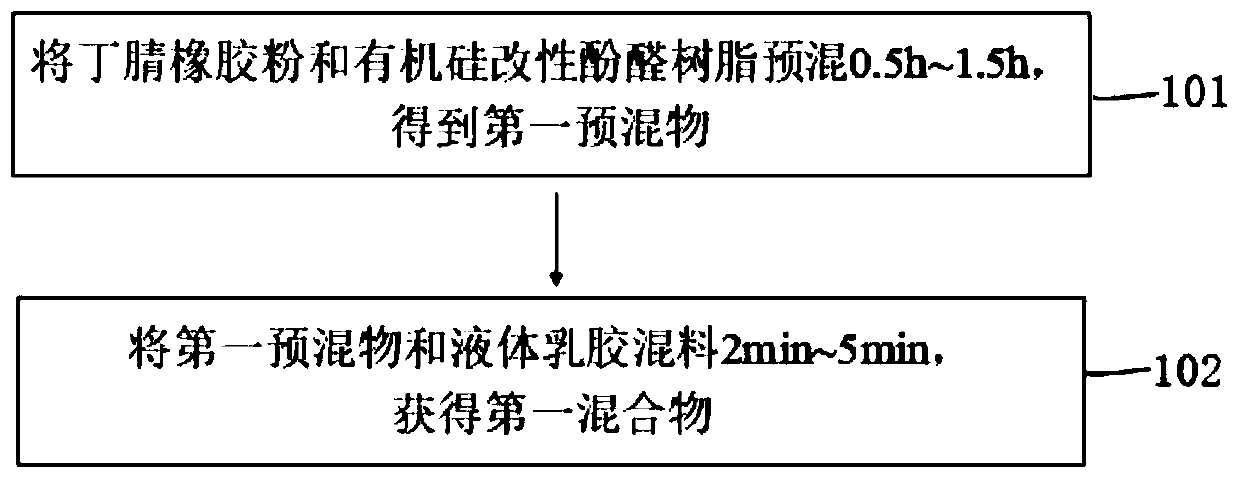

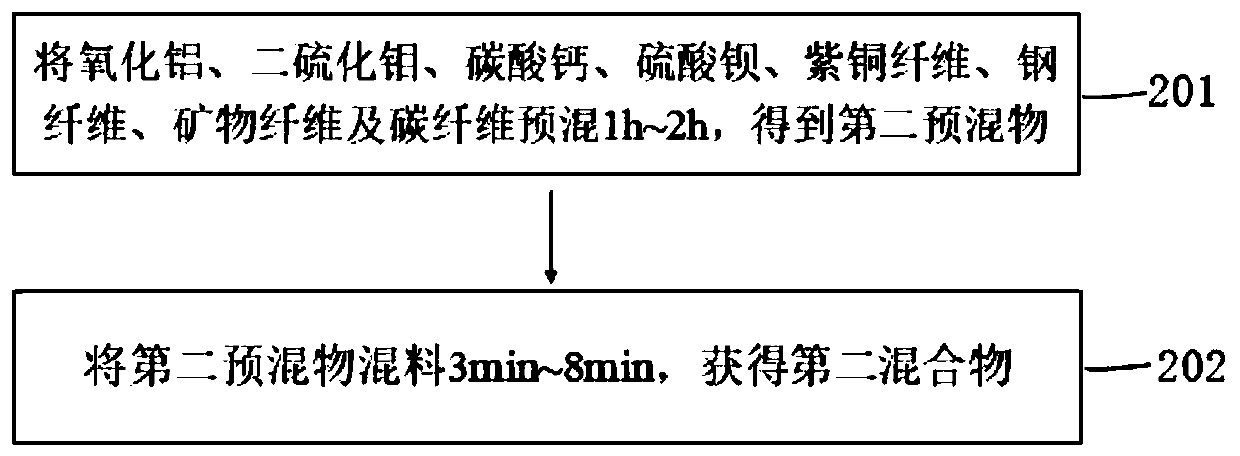

[0061] The embodiment of the present invention provides a method for preparing an organically synthesized friction body. The preparation method of the organic synthesis friction body comprises:

[0062] Mix liquid latex, nitrile rubber powder, silicone modified phenolic resin, rubber accelerator, copper fiber, steel fiber, mineral fiber, carbon fiber, metal filler and inorganic filler evenly, carry out internal mixing, and obtain an organic synthetic friction body. It should be understood that the components and ratios contained in the metal fillers and inorganic fillers mentioned above are consistent with those described above, and will not be discussed here again.

[0063] In this preparation method, the liquid latex replaces the solvent to coat the friction material. In the whole process, the organic synthetic friction body with the above-mentioned beneficial effects can be obtained only by uniformly mixing the raw material components and performing short-term low-temperatu...

Embodiment 3

[0089] The embodiment of the present invention also provides a brake pad, which can be applied to trains such as monorail trains and multi-rail trains, and vehicles such as automobiles, but is not limited thereto. Automobiles include, but are not limited to, cars, trucks, farm vehicles, etc.

[0090] Such as Figure 5 ~ Figure 7 As shown, the brake pad includes: a steel back 1, an organic synthetic friction body 2, a plurality of fixed rings 3 and a plurality of grasping pins 4, the above-mentioned organic synthetic friction body 2 is an integrated organic synthetic friction body, and the organic synthetic friction body Synthetic friction body 2 is the organic synthetic friction body provided in Embodiment 1 of the present invention, and its preparation method is as described in Embodiment 2 of the present invention. A plurality of above-mentioned fixing rings 3 and a plurality of grasping pins 4 are all fixed on the steel back 1 , and the plurality of grasping pins 4 fix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com