Shock-absorption base for transformer

A shock-absorbing base and transformer technology, applied in the field of transformers, can solve the problems of general mechanical strength, easy to generate large noise, limited shockproof effect, etc., and achieve the effect of improving structural strength and stability, and not being prone to noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

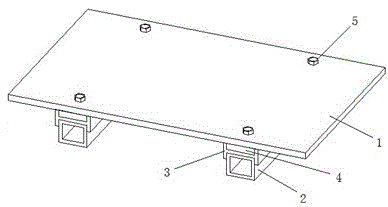

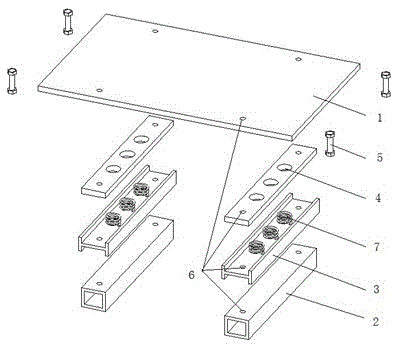

[0014] Such as figure 1 , 2 As shown, a shock-absorbing base for a transformer includes a pair of square tube steel 2, H-shaped steel 3 and shock-absorbing rubber plate 4 located below the transformer bottom plate 1, and the square tube steel 2 is arranged in the lower groove of the H-shaped steel 3 Among them, the shock-absorbing rubber plate 4 is arranged in the upper groove of the H-shaped steel 3, and the two ends of the transformer bottom plate 1, the square tube steel 2, the H-shaped steel 3 and the shock-absorbing rubber plate 4 are symmetrically provided with fixing holes 6, The transformer bottom plate 1, square tube steel 2, H-shaped steel 3 and shock-absorbing rubber plate 4 can be fixedly connected by inserting the fixing bolts 5 into the fixing holes 6 in sequence. At least one mounting hole 4, the upper groove of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com