Tensioning device for a traction mechanism, in particular a belt or a chain

A technology of tensioning device and traction mechanism, applied in belt/chain/gear, transmission, mechanical equipment, etc., can solve problems such as noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

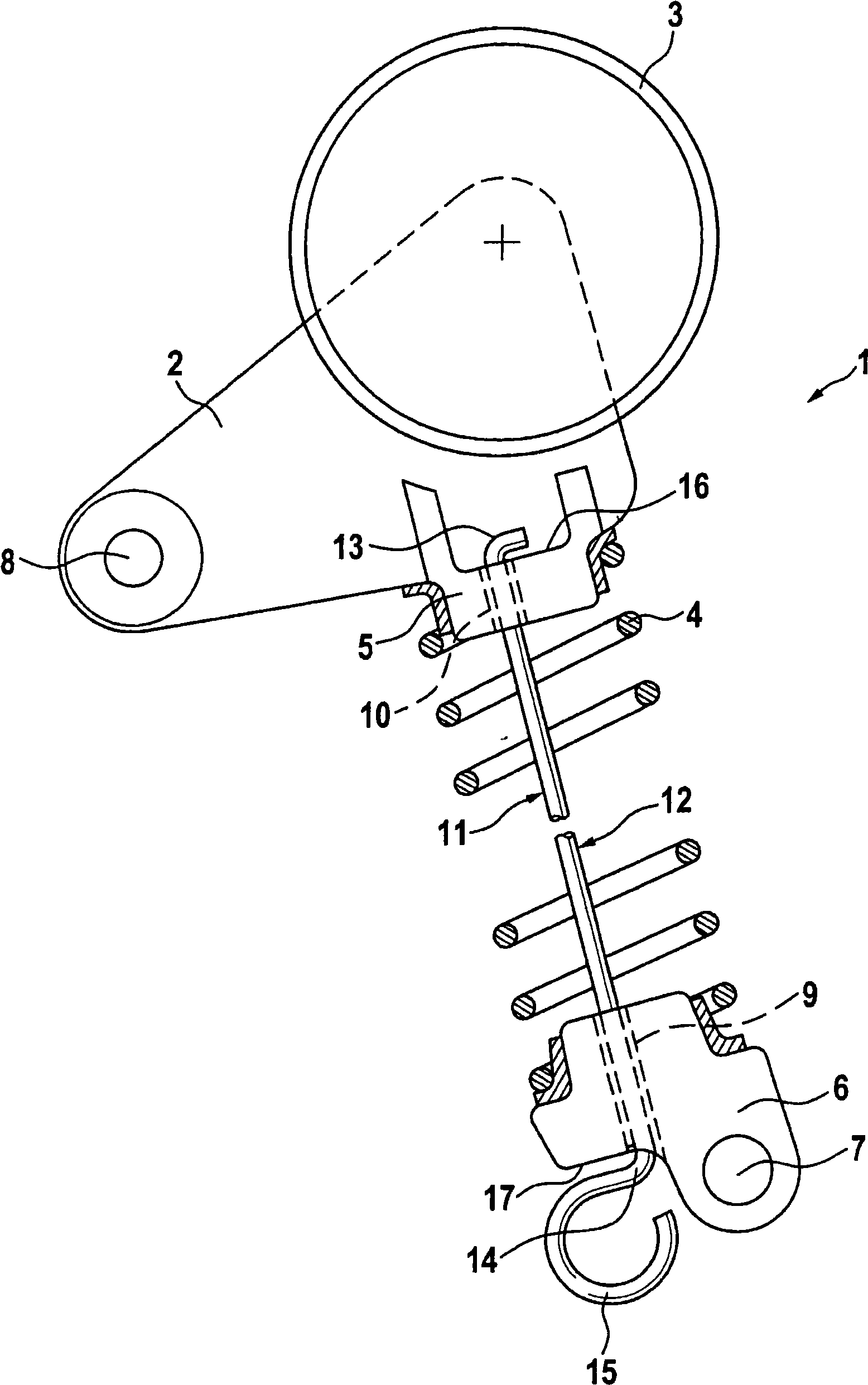

[0018] figure 1 A tensioning device 1 according to the invention is shown, said device 1 comprising a tensioning rod 2 on which a tensioning roller 3 is arranged here, by means of which the traction mechanism is guided in the assembled position, Especially for guiding the belt. Furthermore, the tensioning device 1 comprises a tensioning spring 4 which is here embodied as a helical spring and rests with its end facing the tensioning rod 2 on a spring support 5 which is connected to the tensioning spring 5 . The rod 2 is firmly connected or is part of the tension rod 2 . The other end of the tension spring 4 is placed on the spring holder 6 . The spring carrier 6 is fastened to a third object, for example a motor vehicle engine or the like, for which fastening holes 7 are used, via which the tensioning device is pivotally mounted there. In a corresponding manner, the tensioning lever 2 also has fastening holes 8 , by means of which the tensioning lever 2 can be pivotably fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com