Vulcanization method for producing low-wear carbon fiber automobile clutch friction plate

A carbon fiber and friction plate technology is applied in the field of vulcanization for the production of low-wear carbon fiber automobile clutch friction plates, which can solve the problems of inaccurate raw material ratio, insufficient friction plate performance, and insufficient craftsmanship, so as to reduce labor costs and stabilize product quality. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with examples. The examples are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

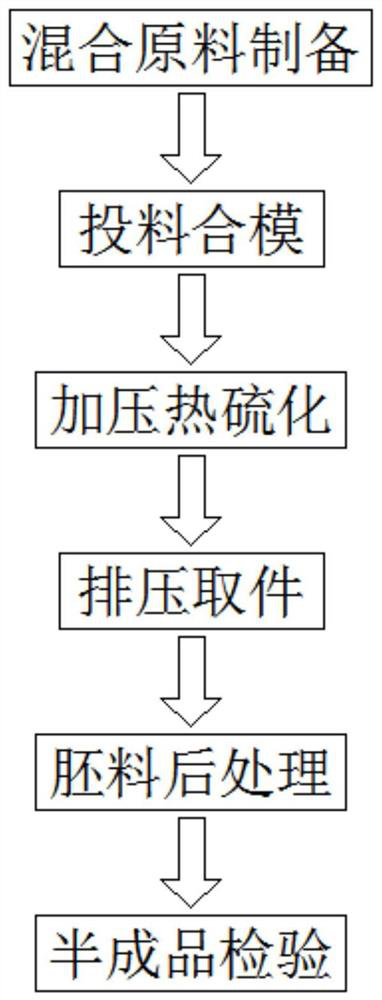

[0028]according tofigure 1As shown, this embodiment provides a vulcanization method for producing low-wear carbon fiber automotive clutch friction plates, which includes the following steps:

[0029]Step 1: Preparation of mixed raw materials

[0030]First select quantitative carbon fibers, inorganic ceramic fiber materials, potassium hexatitanate whiskers, aramid fibers, resin binders, fiber reinforcing agents, process regulators, friction regulators, graphite particles, and boron nitride through the batching machine. And bamboo charcoal fiber, and then put the finished ingredients into the mixing machine for mixing and mixing. After mixing into powder, the mixed raw materials are prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com