Three-jacquard warp-knitting machine

A technology of jacquard warp and knitting machines, applied in the field of knitting machinery, which can solve problems such as limited product colors and inability to meet production needs, and achieve the effects of long service life, low noise, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

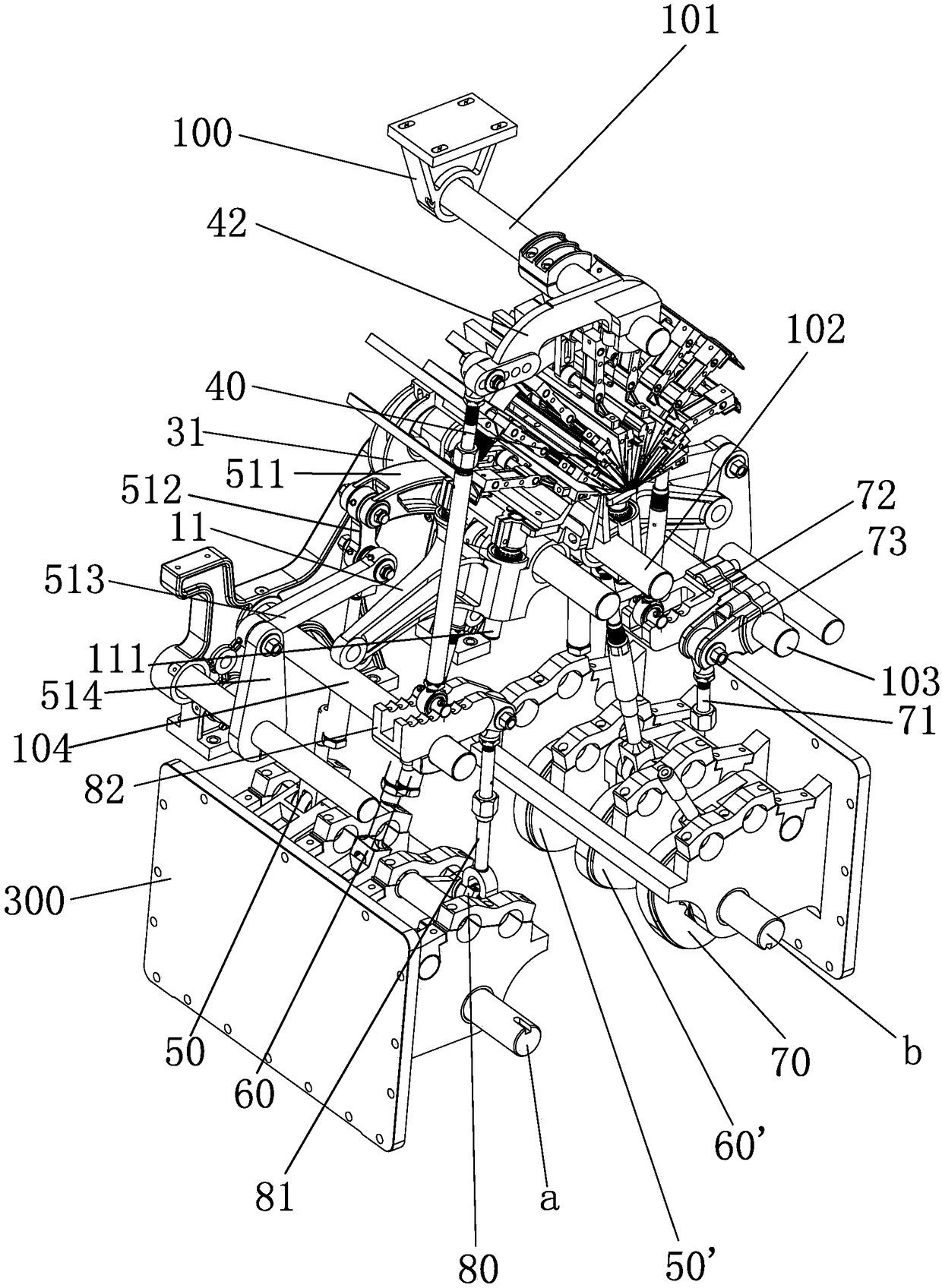

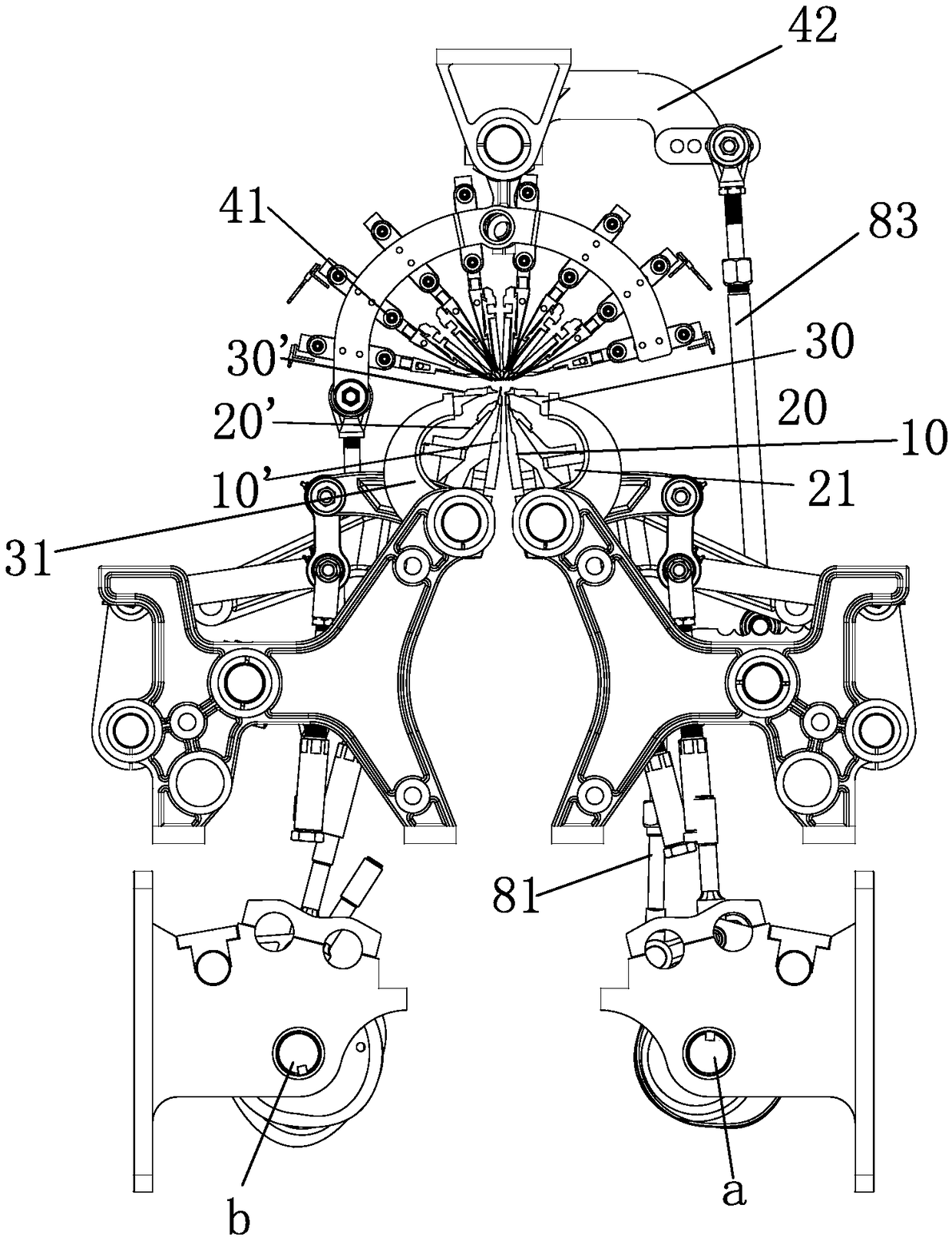

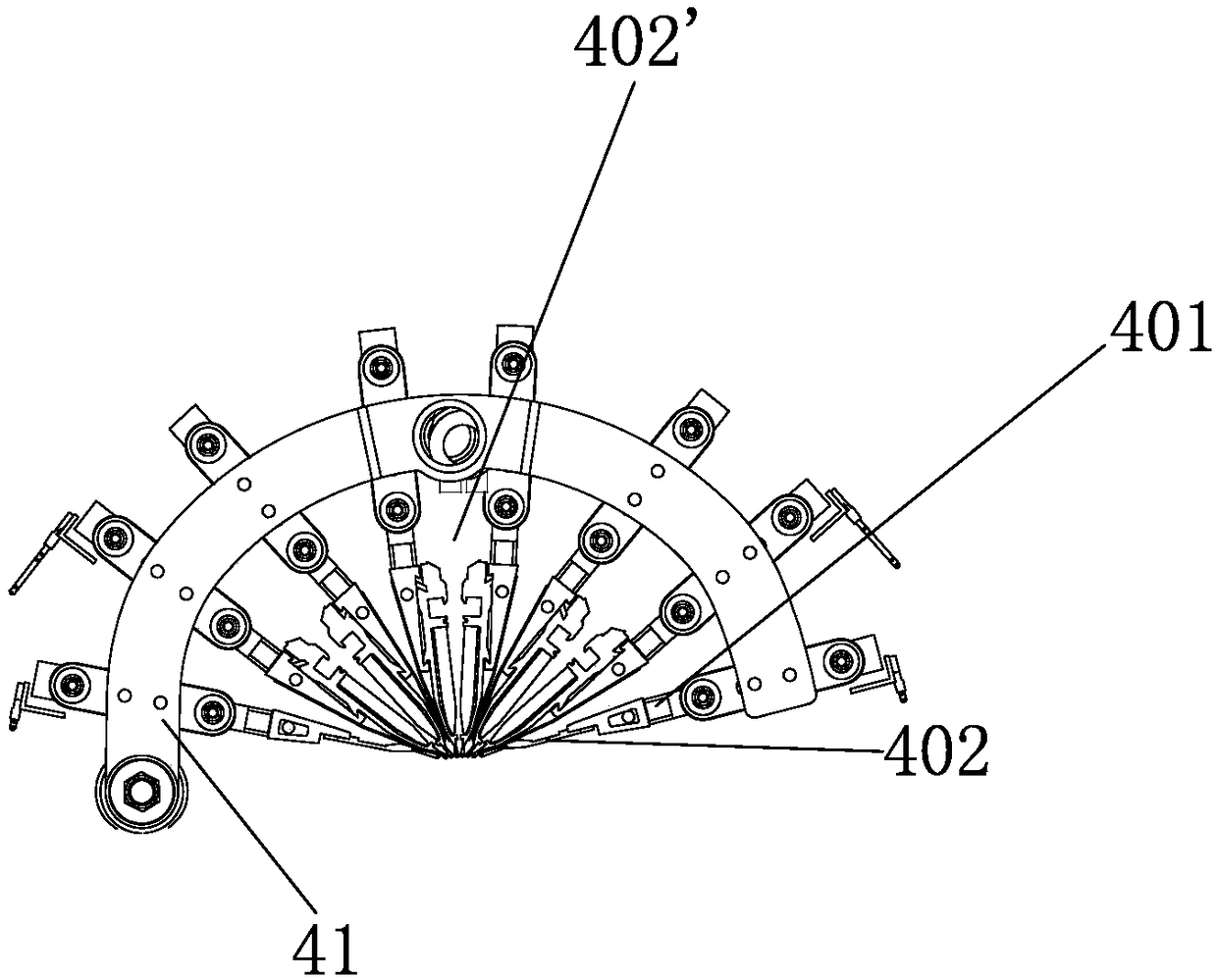

[0031] refer to figure 1 , figure 2 and image 3 , a three jacquard warp knitting machine, comprising a frame 100 and a knitting device, a bar device, and a transmission device installed on the frame 100, and the knitting device includes a front knock-off part 10 and a rear knitting part respectively symmetrically arranged. Stripping part 10', front needle bed part 20 and rear needle bed part 20', front sinker part 30 and rear sinker part 30';

[0032] Described front take-off section 10 and rear take-off section 10' comprise respectively the guide arm assembly 11 that is connected on the frame 100 and the take-off plate that is installed on the described guide arm assembly 11;

[0033] The front needle bed part 20 and the rear needle bed part 20' respectively include a latch needle bed and a bracket assembly 21 for dynamically connecting the latch needle bed with the guide arm assembly 11, and the latch needle bed is installed on On the bracket assembly 21, a latch needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com