High carbon semi-ceramic braking material

A technology for braking materials and motor vehicles, applied in friction linings, mechanical equipment, etc., can solve problems such as high noise, high manufacturing cost, and easy damage

Inactive Publication Date: 2005-01-19

上海华化摩擦材料有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since this type of brake material does not contain organic components, it has a stable high-temperature friction coefficient, small fading, and good wear resistance, but the manufacturing cost is hig

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Login to View More

Abstract

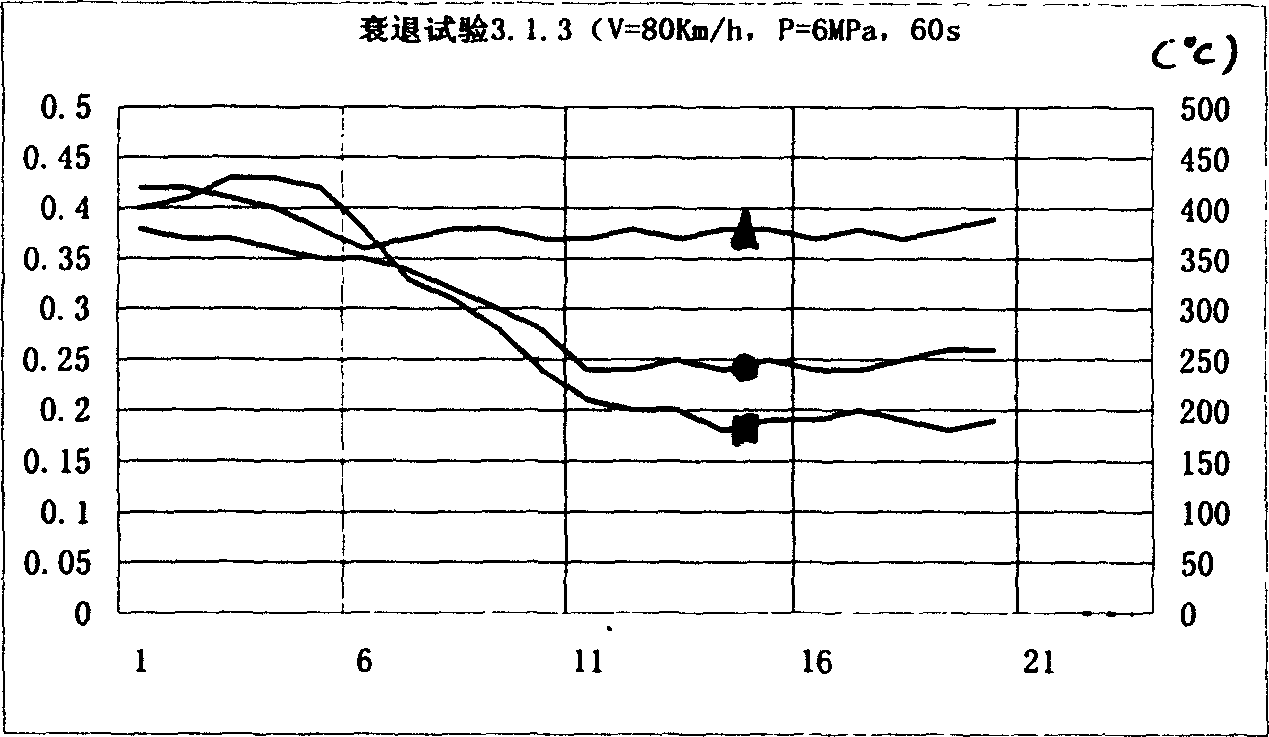

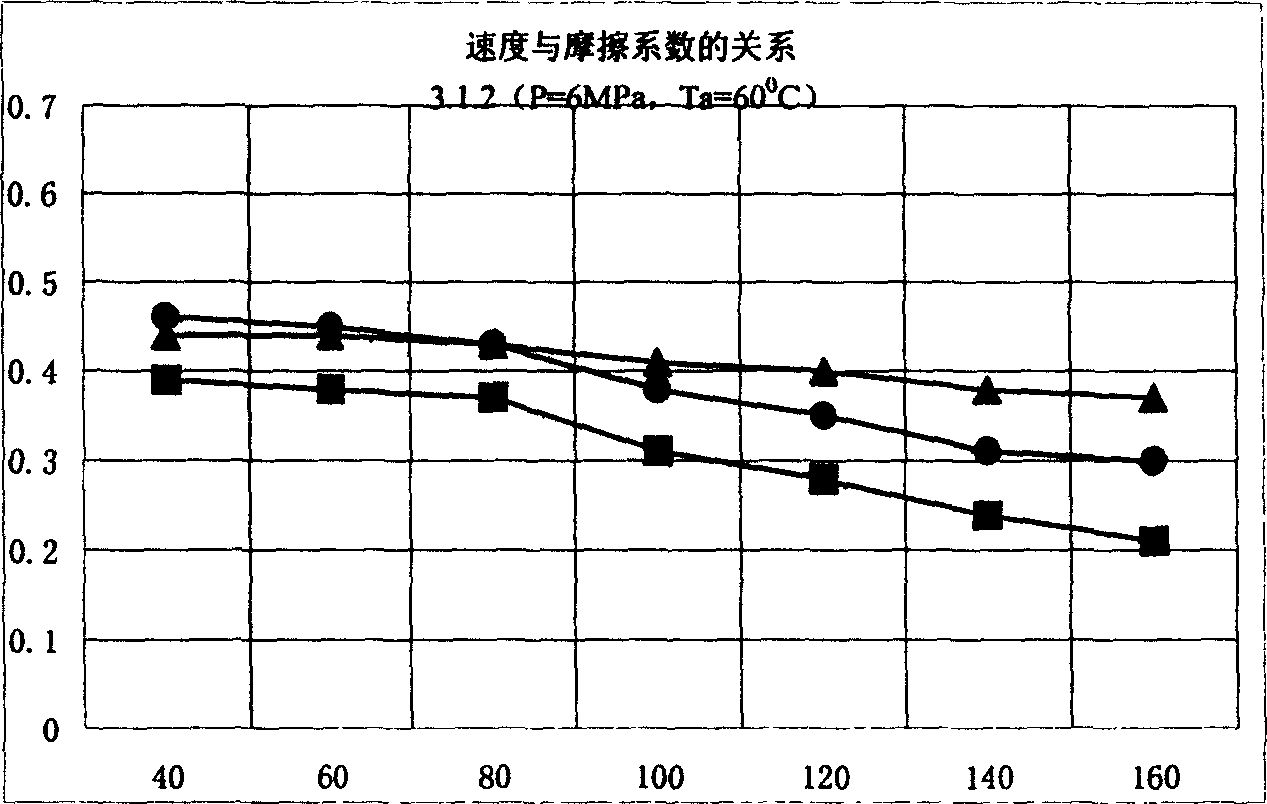

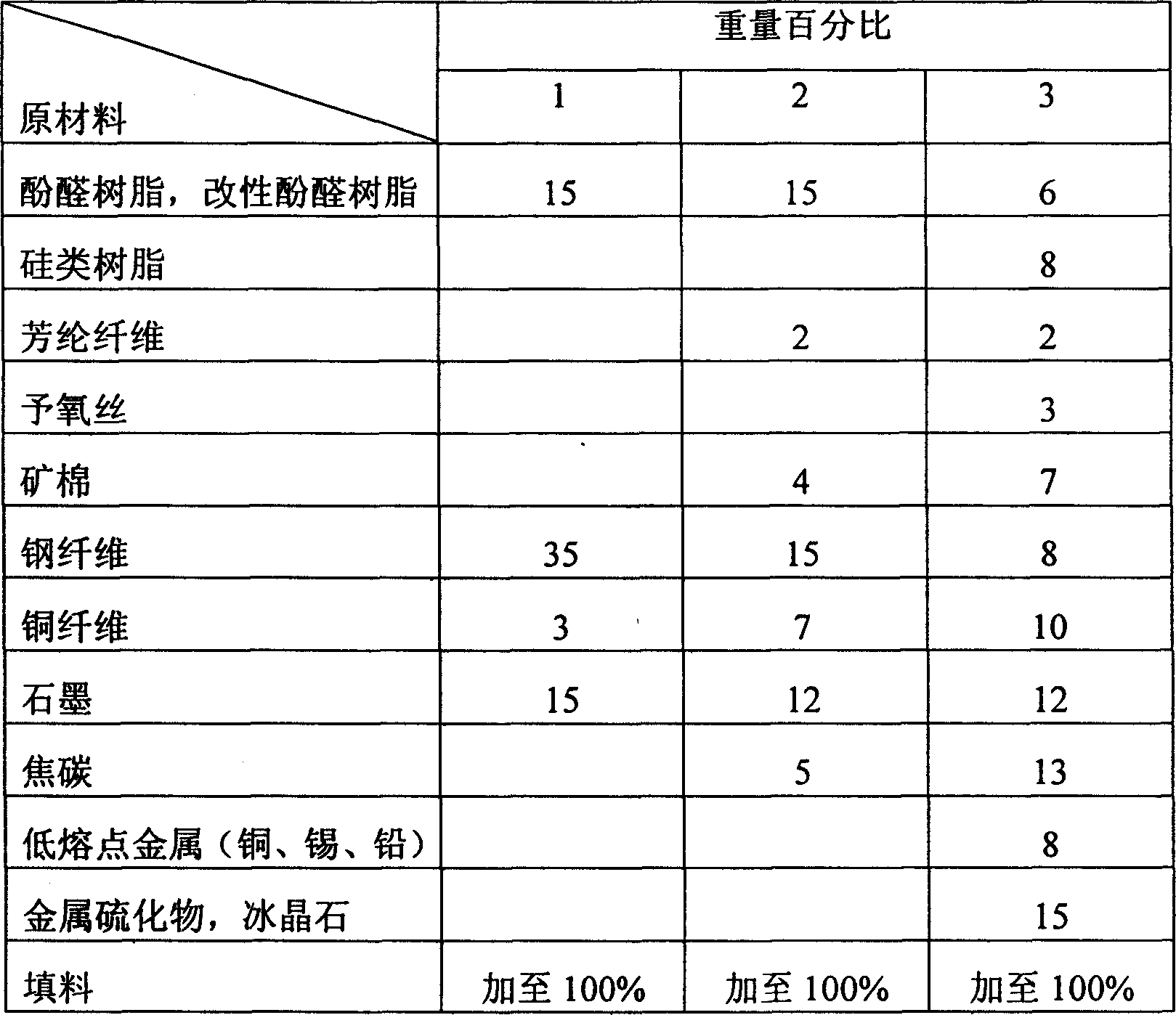

The invention discloses an automobile braking material, comprising matrix 4~8%, low melting point metal 5~15%, inorganic binder 15~30%, polysiloxane 5~15%, fortifying fibre 15~35% and packing material 15~30%. The change of the friction coefficient of the braking material along with the change of the temperature approaches to zero, In addition, it also has advantages as high degree of porosity, low noise, no-harming to the mating plate and high abrasion resistance.

Description

technical field [0001] The invention relates to a motor vehicle braking material, in particular to an automobile braking material. Background technique [0002] At present, most automobile brake materials are organic brake materials, which are composed of three major parts: matrix material (adhesive), reinforcing fiber, and filler (including friction modifier). The matrix material is phenolic resin, modified phenolic resin, rubber or their mixture; the reinforcing fiber is steel fiber, copper fiber, inorganic fiber, organic fiber, mineral fiber or their mixture; the filler is barite powder, calcium carbonate, oxide Magnesium, limestone, lead sulfide, graphite, coke, zinc oxide, iron oxide, molybdenum disulfide, friction powder, tire powder, chromite powder, antimony sulfide, pyrite, etc. Organic type braking materials have the advantages of low cost, simple manufacturing process, low noise, and not easy to damage the dual, but because of their high organic content (15-25%),...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16D69/02

Inventor 邹盛根金国兴梁文斌董志敏

Owner 上海华化摩擦材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com