Synthetic friction material and preparation method and application thereof

A technology of friction material and compounding agent, which is applied in the field of synthetic friction material and its preparation, and can solve the problems of dual wear, unstable friction coefficient, brake noise and strong smell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

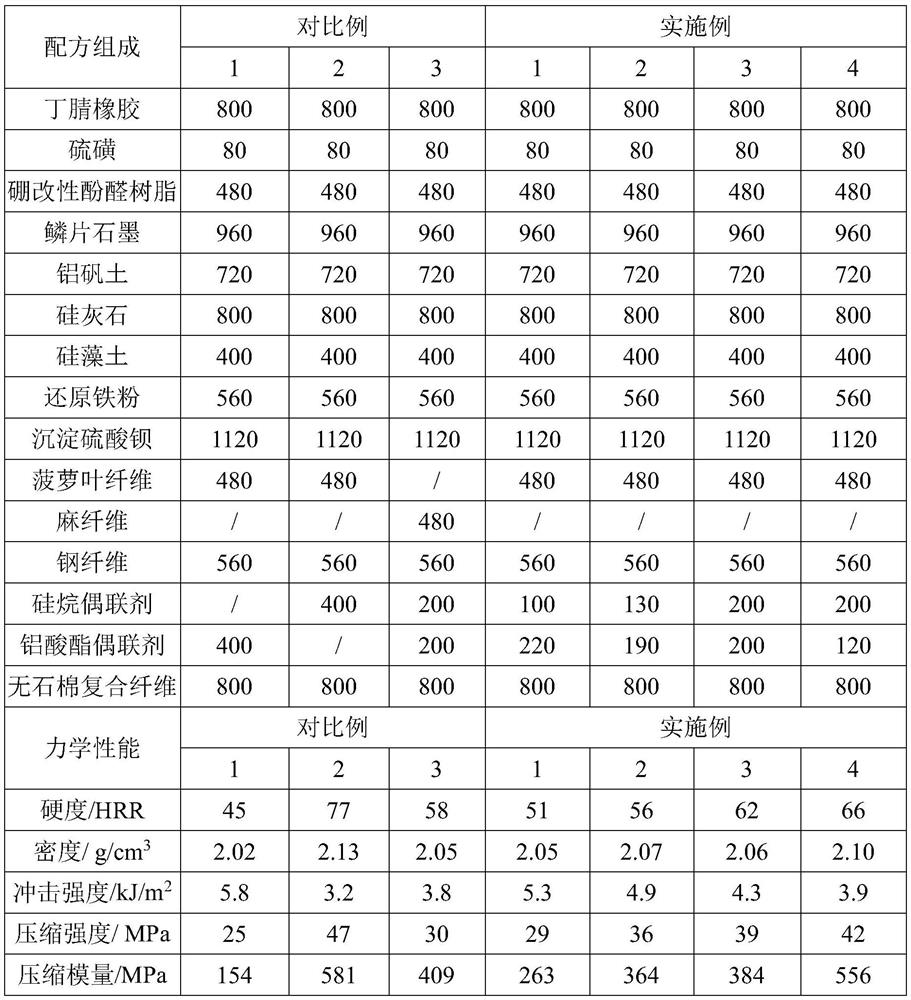

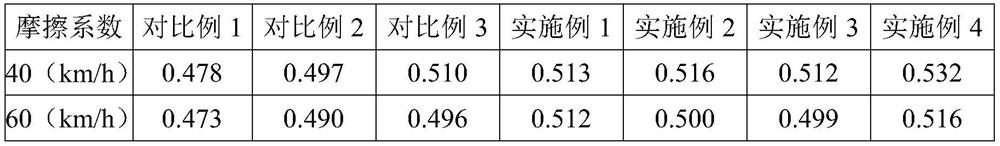

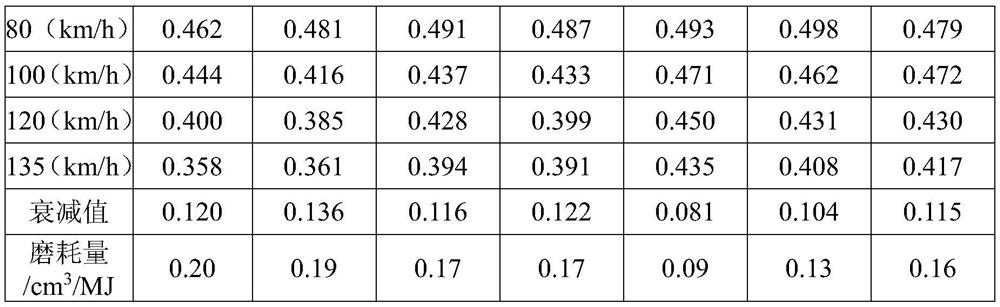

Embodiment 1

[0059] This embodiment provides a synthetic friction material, the preparation method of which includes:

[0060] 1. Precipitated barium sulfate 1120g, bauxite 720g, reduced iron powder 560g, wollastonite 800g, diatomite 400g, pineapple leaf fiber 480g, silane coupling agent 100g, aluminate coupling agent 220g, asbestos-free composite Fiber (as inorganic mineral composite fiber) 800g, steel fiber 560g, flake graphite 960g are weighed and then poured into the mixer, the machine speed is set to 200r / min, and the stirring time is 25min to obtain a uniformly mixed composition .

[0061] 2. Mix the above composition with 800g of nitrile rubber, 80g of sulfur, and 480g of boron-modified phenolic resin, and banbury for 12min in a banbury mixer under the condition that the banbury temperature does not exceed 95°C. The banbury pressure is 0.9MPa, and banbury After completion, it is crushed to obtain a friction material mixture, and the crushed particle size is ≤4mm. The friction mate...

Embodiment 2

[0063] This embodiment provides a synthetic friction material, the preparation method of which includes:

[0064] 1. Weigh 1120g of precipitated barium sulfate, 720g of bauxite, 560g of reduced iron powder, 800g of wollastonite, 400g of diatomaceous earth, 480g of pineapple leaf fiber, 130g of silane coupling agent, 190g of aluminate coupling agent, asbestos-free 800g of composite fibers, 560g of steel fibers, and 960g of graphite flakes were poured into the mixing machine, the machine speed was set at 200r / min, and the stirring time was 25min, and a uniformly mixed composition was obtained.

[0065] 2. Mix the above composition with 800g of nitrile rubber, 80g of sulfur, and 480g of boron-modified phenolic resin, and then use a banbury mixer for banburying, banburying for 12min under the condition that the banburying temperature does not exceed 95°C, and the banburying pressure is 0.9MPa, crushed after the banburying is completed to obtain the friction material mixture, the c...

Embodiment 3

[0067] This embodiment provides a synthetic friction material, the preparation method of which includes:

[0068] 1. Weigh 1120g of precipitated barium sulfate, 720g of bauxite, 560g of reduced iron powder, 800g of wollastonite, 400g of diatomaceous earth, 480g of pineapple leaf fiber, 200g of silane coupling agent, 200g of aluminate coupling agent, asbestos-free 800g of composite fibers, 500g of steel fibers, and 960g of graphite flakes were poured into a mixer, the machine speed was set at 200r / min, and the stirring time was 25min to obtain a uniformly mixed composition.

[0069] 2. Mix the above composition with 800g of nitrile rubber, 80g of sulfur, and 480g of boron-modified phenolic resin, and then use a banbury mixer for banburying, banburying for 12min under the condition that the banburying temperature does not exceed 95°C, and the banburying pressure is 0.9MPa, crushed after the banburying is completed to obtain the friction material mixture, the crushed particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com