Environment-friendly building construction waste recycling device

A technology for building construction and recycling devices, which is applied in construction waste recycling, furniture waste recycling, recycling technology, etc., and can solve problems such as screening, inability to fully classify construction waste, and low efficiency of waste classification and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

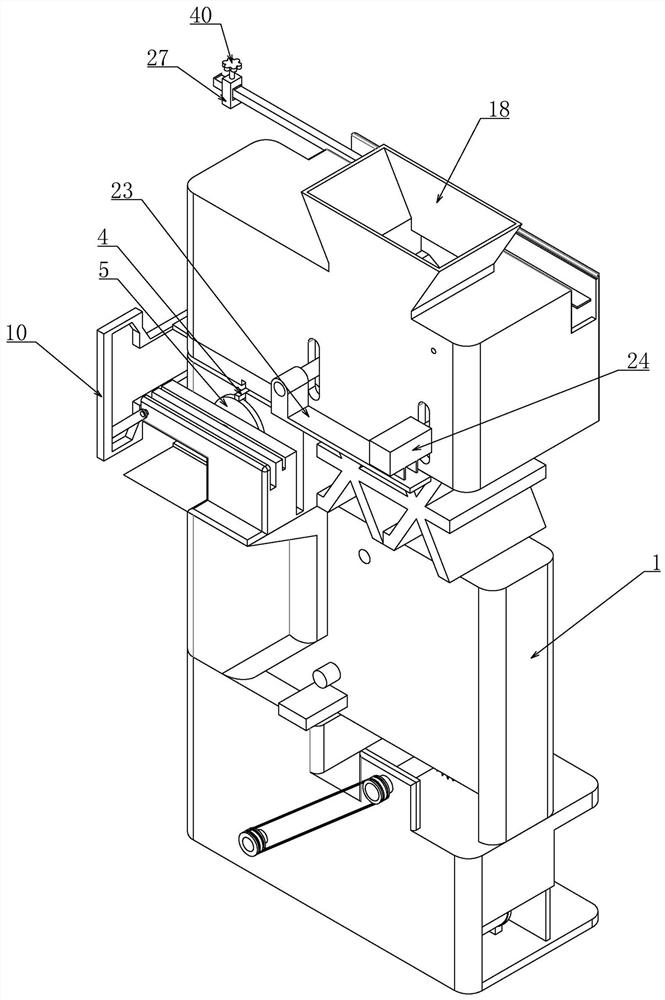

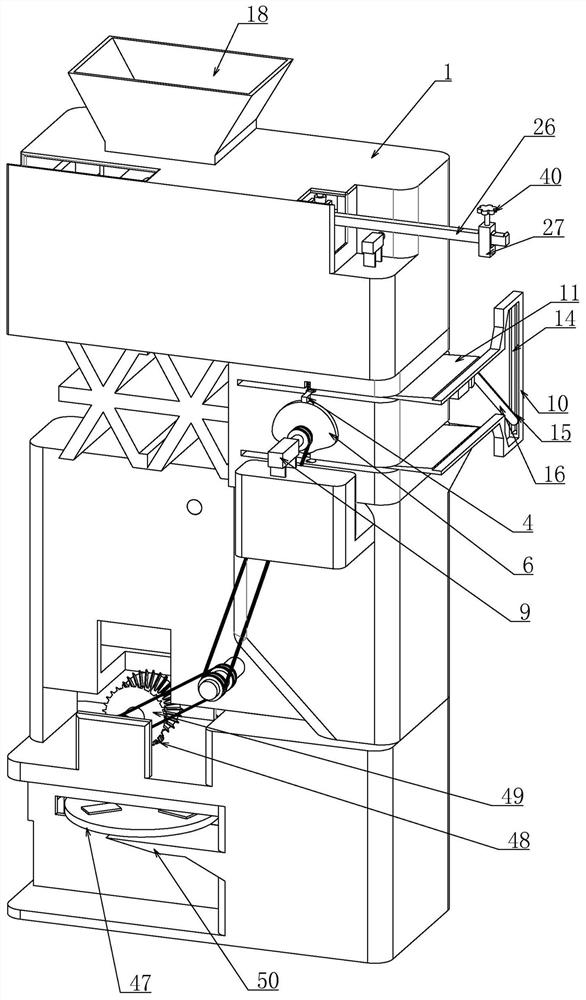

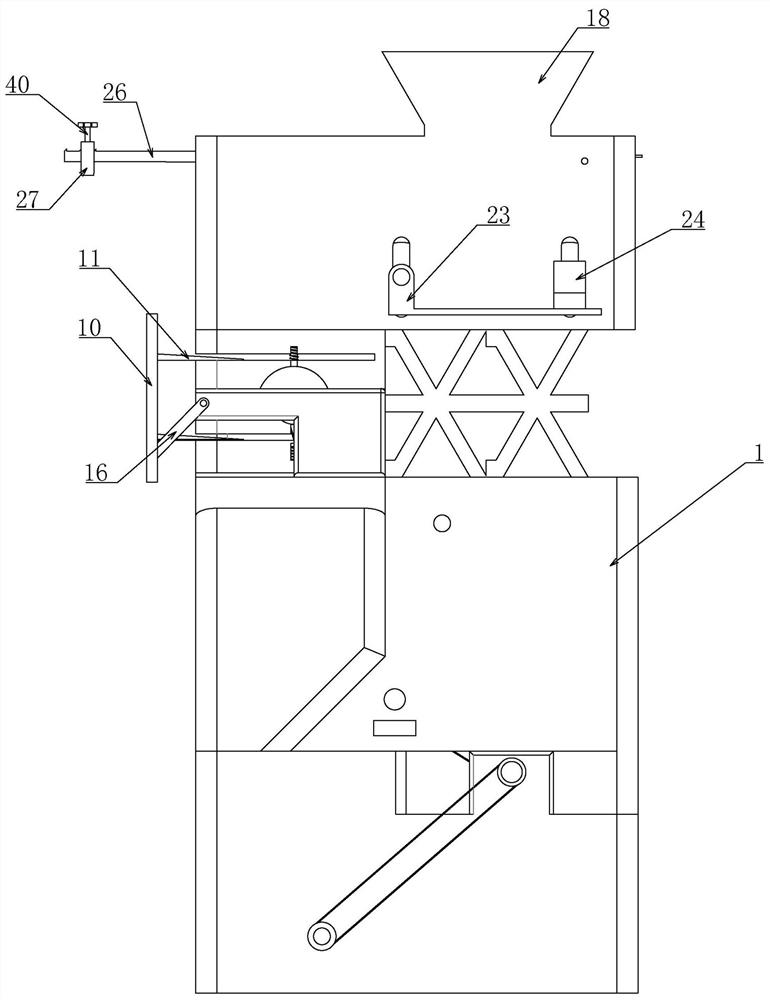

Embodiment 1

[0033] Embodiment 1, an environment-friendly building construction waste recovery device, comprising a frame 1, characterized in that two sets of screens 2 are vertically slidably connected to the channel in the frame 1, and the two sets of screens 2 are vertically connected to each other. Arranged at intervals, the distance between the two groups of screens 2 should meet the length of the rod-shaped waste as far as possible, so that the rod-shaped waste can pass through the upper screen 2 and then enter the lower screen 2. The screen 2 There are multiple groups of rectangular slots 3 arranged at intervals on the top, and the slots 3 on the two groups of screens 2 are arranged at ninety degrees. Block stones, concrete clots can leak from the elongated holes 3, and the purpose of setting two groups of screens 2 is to allow these finely broken stones, concrete blocks, and iron nails to pass through the two groups of screens 2 smoothly. After the long holes 3 of the wooden strips...

Embodiment 2

[0035] Embodiment 2. On the basis of Embodiment 1, the reciprocating sweeping device includes a U-shaped bar 10 transversely connected to the frame 1, and two poles of the U-shaped bar 10 are respectively transversely connected with a surface The oblique baffle plate 11, the U-shaped bar 10 is laterally clamped on the frame 1 through two sets of baffle plates 11, the baffle plate 11 is sandwiched between the screen 2 and the frame 1, and at this position The screen 2 is driven to the extreme position by the cam 6, and the lower end of the baffle plate 11 is attached to the screen 2 on the corresponding side, and also includes a first gear 12 coaxially installed on the transmission shaft 5. The first gear 12 is meshed with the second gear 13 that is rotatably connected to the frame 1. The cam 6 is formed by butting two groups of semicircular plates with different radii. The large semicircular plate is the radius of the small semicircular plate. twice, and the radius of the firs...

Embodiment 3

[0037] Embodiment 3, on the basis of Embodiment 1, the described uniform feeding device includes a feeding hopper 18 installed on the upper end of the frame 1, the feeding hopper 18 is used to hold bulk materials, and the described feeding hopper 18 The left end of the lower end is connected with a long vertical plate 19, and the right end is connected with a short vertical plate 20. The frame 1 is vertically connected with two groups of first pulleys 21 placed below the lower hopper. There is a vertical strip-shaped hole structure, and the rotating shaft of the first pulley 21 is inserted into the strip-shaped hole-shaped structure, so that it can only move along the vertical direction. A first belt 22 is provided, wherein one end of the rotating shaft of one set of first pulleys 21 is connected to the connection plate 23, and one end of the rotating shaft of the other set of first pulleys 21 is connected with the output shaft of the first motor 24 installed on the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com