Rotational vibration disc

A technology of rotating vibrating disk and rotating disk, applied in the field of machinery, can solve the problems of slow speed and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

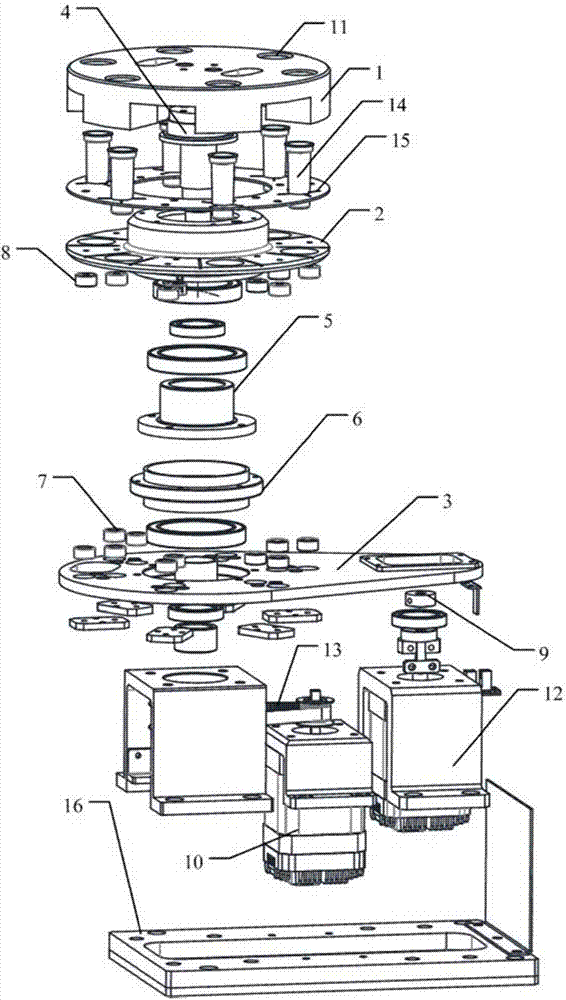

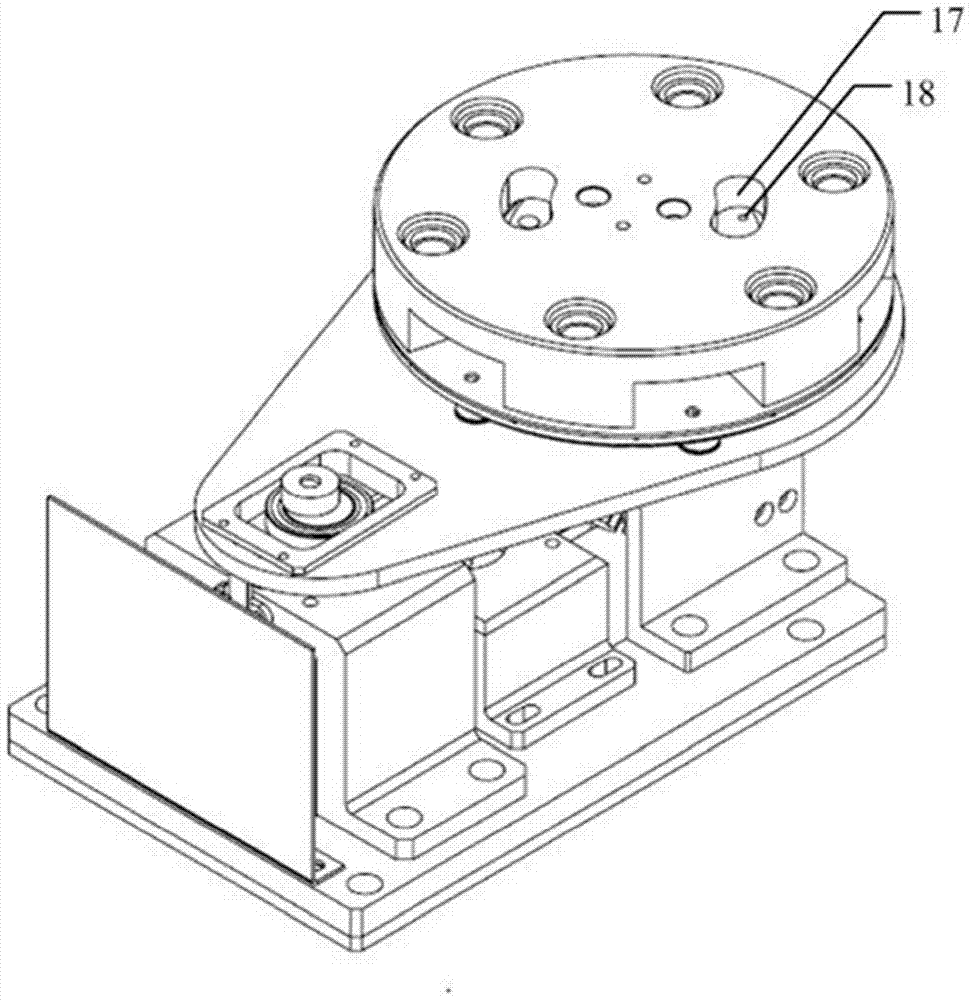

[0033] The embodiment of the present invention provides a rotating vibrating plate, which can be operated automatically, and vibrates the buffer solution cup during the rotating process, thereby improving the detection efficiency.

[0034] see figure 1 and figure 2 , an embodiment of a rotating vibrating plate provided by an embodiment of the present invention, specifically includes:

[0035] The rotating disk 1 is connected to the main shaft 4 and rotates accordingly. There is a follow-up tray 2 under the rotating disk 1. The follow-up tray 2 is assembled with the main shaft 4 through the first bearing group 5. There is a vibrating tray below the follow-up tray 2. 3. The vibrating tray 3 is assembled with the main shaft 4 through the second bearing group 6, and the main shaft 4 is powered by the power part; the rotating disc 1 and the follower tray 2 have a buffer cup 11;

[0036] The vibrating tray 3 has a square hollow, and an eccentric wheel 9 is limited by the frame of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com