Defoaming packaging process of electronic component

A technology for electronic components and packaging technology, applied in the field of defoaming packaging technology, can solve the problems of poor protection effect of electronic components, cracking of epoxy resin layers, etc., to achieve good protection, eliminate voids, and achieve good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

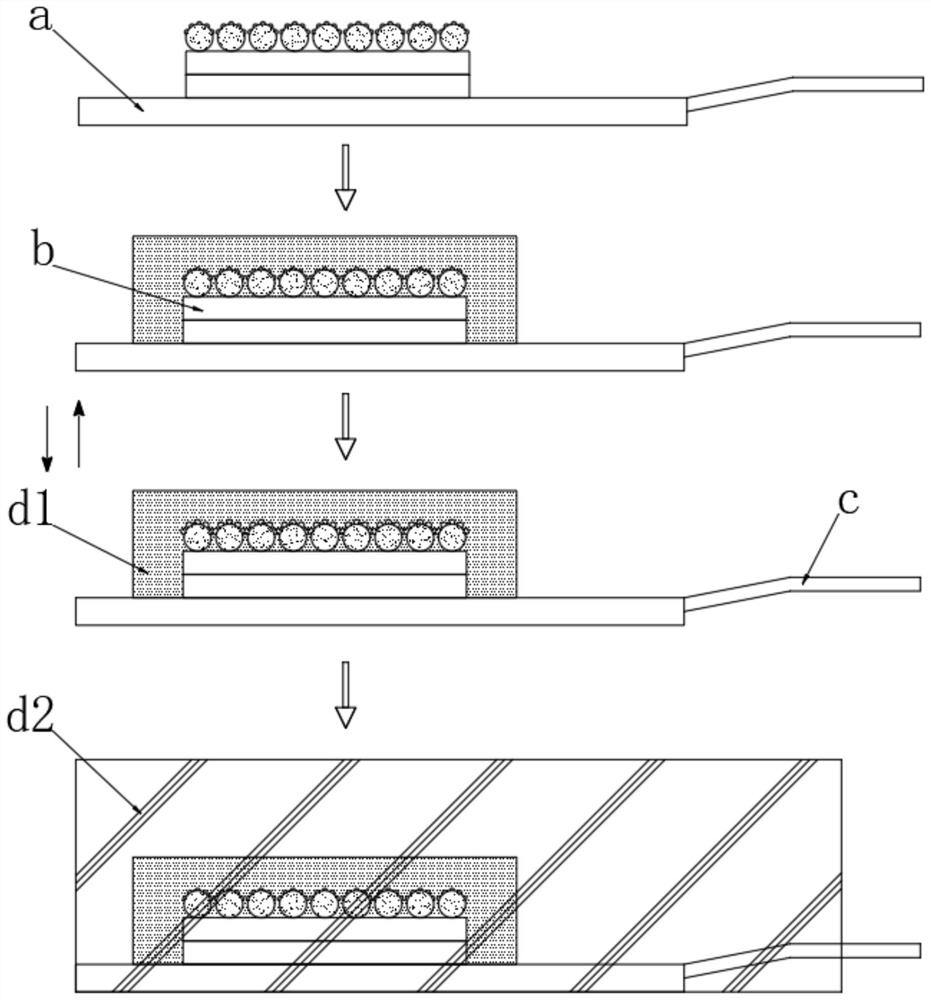

[0046] See figure 1 , An electronic component defoamemic packaging process, including the following steps:

[0047] S1, first install the chip on the substrate, then lay on a layer of breathing moving in the chip;

[0048] S2, the pretreatment of the inner breathing moving ball, and then a layered cast epoxy resin;

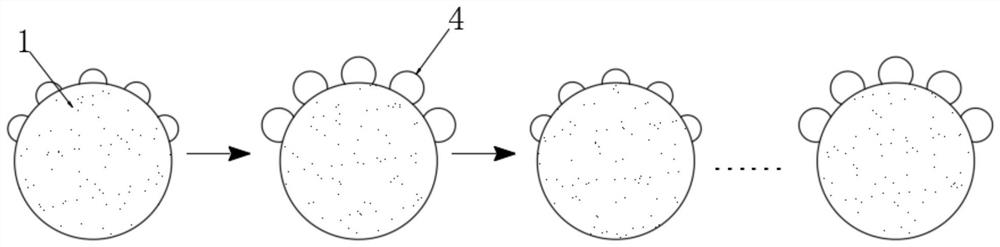

[0049] S3, the casting of the epoxy resin of the first layer, after the pouring of the substrate, the internal breathing moving ball is expanded, and the rushing treatment is processed, so that the internal breathing moving ball is restored, and the heating is repeated multiple times. The treatment of rushing, so that the internal respiratory moving ball continues to repeat the expansion-restoration process, exhibiting a "breathing" state, from the inside to the epoxy resin, eliminate the void inside the epoxy resin;

[0050] After S4, the first layer of epoxy resin is cooled and fixed, the casting of the second layer of epoxy resin is carried out, and naturally coole...

Embodiment 2

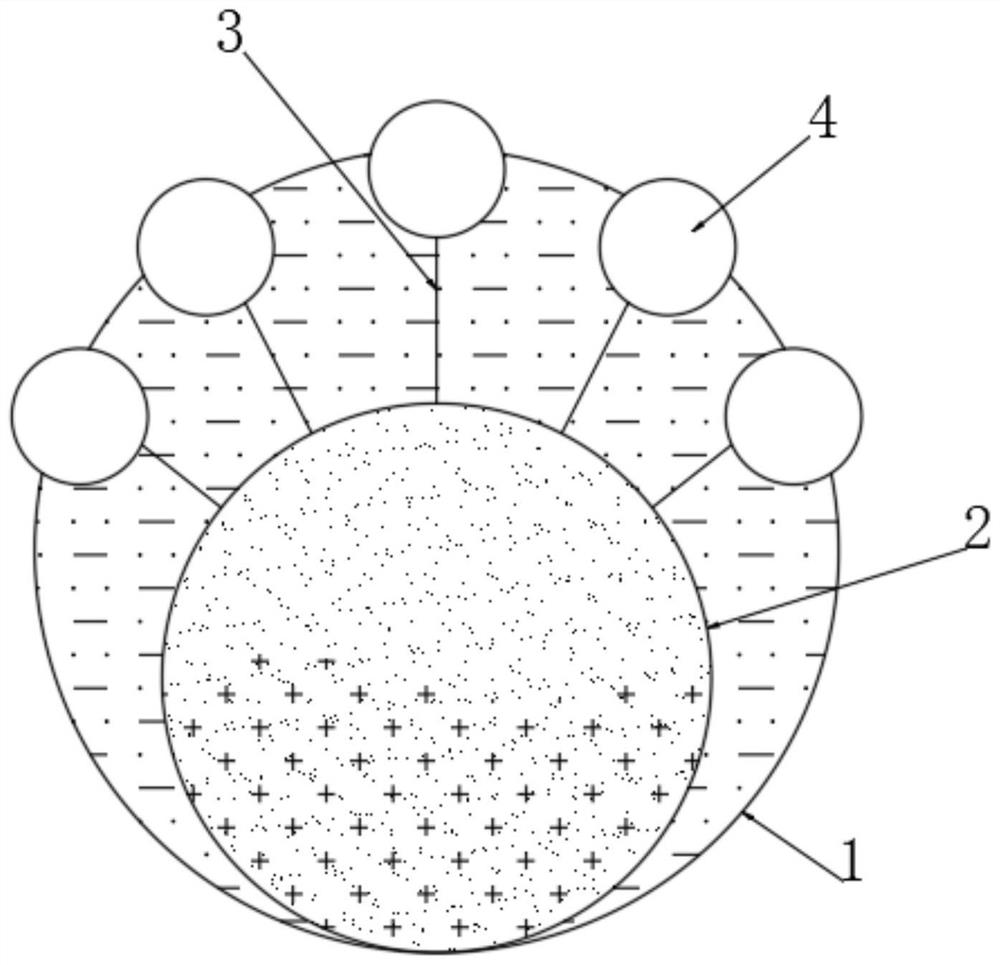

[0059] See Figure 4-5 The difference from the first embodiment is that the pulley 3 is not provided, and the outer spherical shell 1 is made of an elastic material, and the outer extrusion ball 4 is made of a hard material, so that during heating, internal breathing ball core 2 After expanding, the outer spherical shell 1 is expanded outward after the extrusion of insulating oil, thereby greater the range of vibration of the epoxy resin, and the effect of eliminating voids is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com