Disc brake calliper for a motor vehicle

A technology of disc brakes and brake calipers, applied in the field of brake calipers, can solve the problems of reduced rigidity of the brake calipers shell, brake squeaking, vibration problems, etc., and achieve the effect of avoiding noise problems and suppressing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

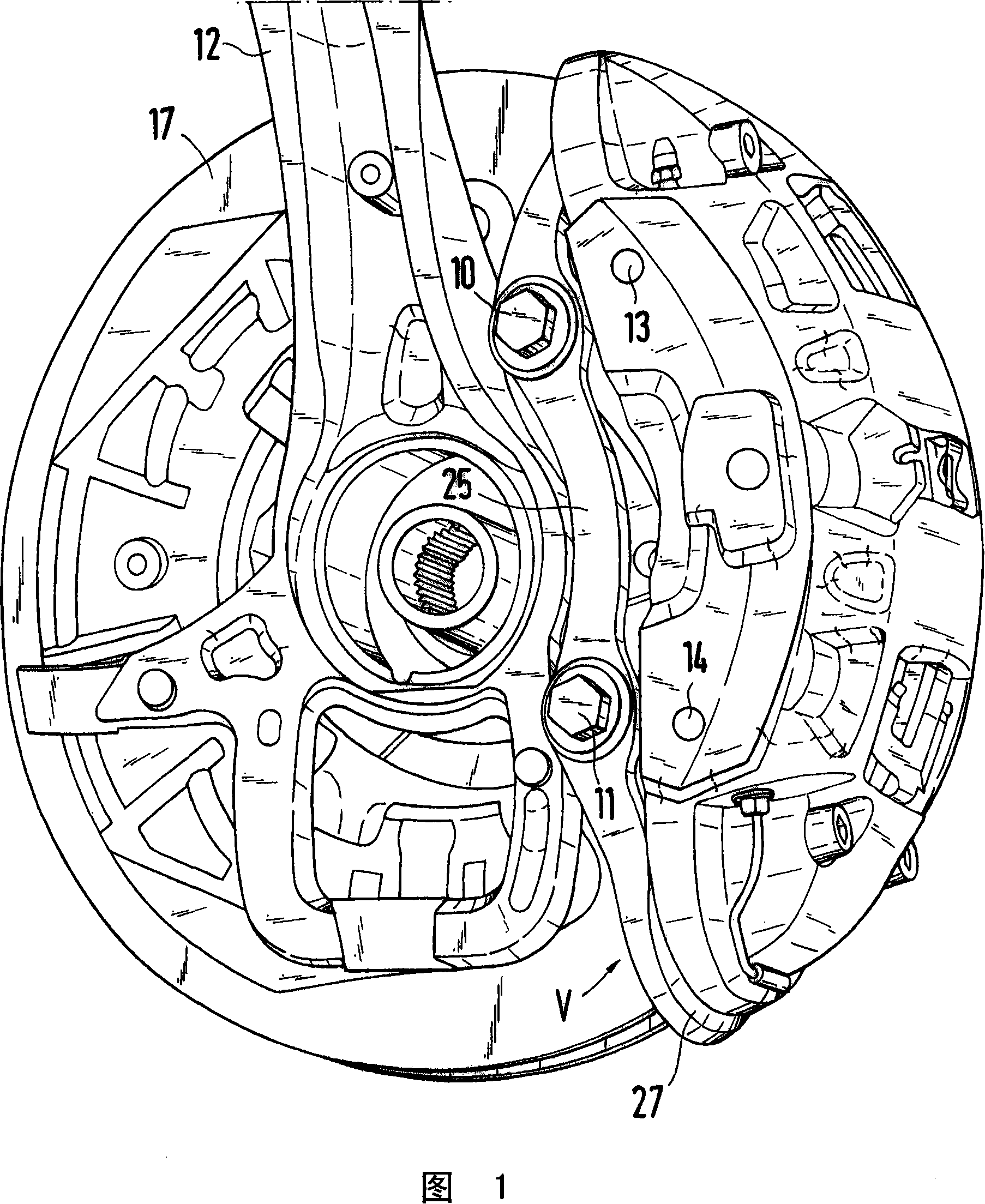

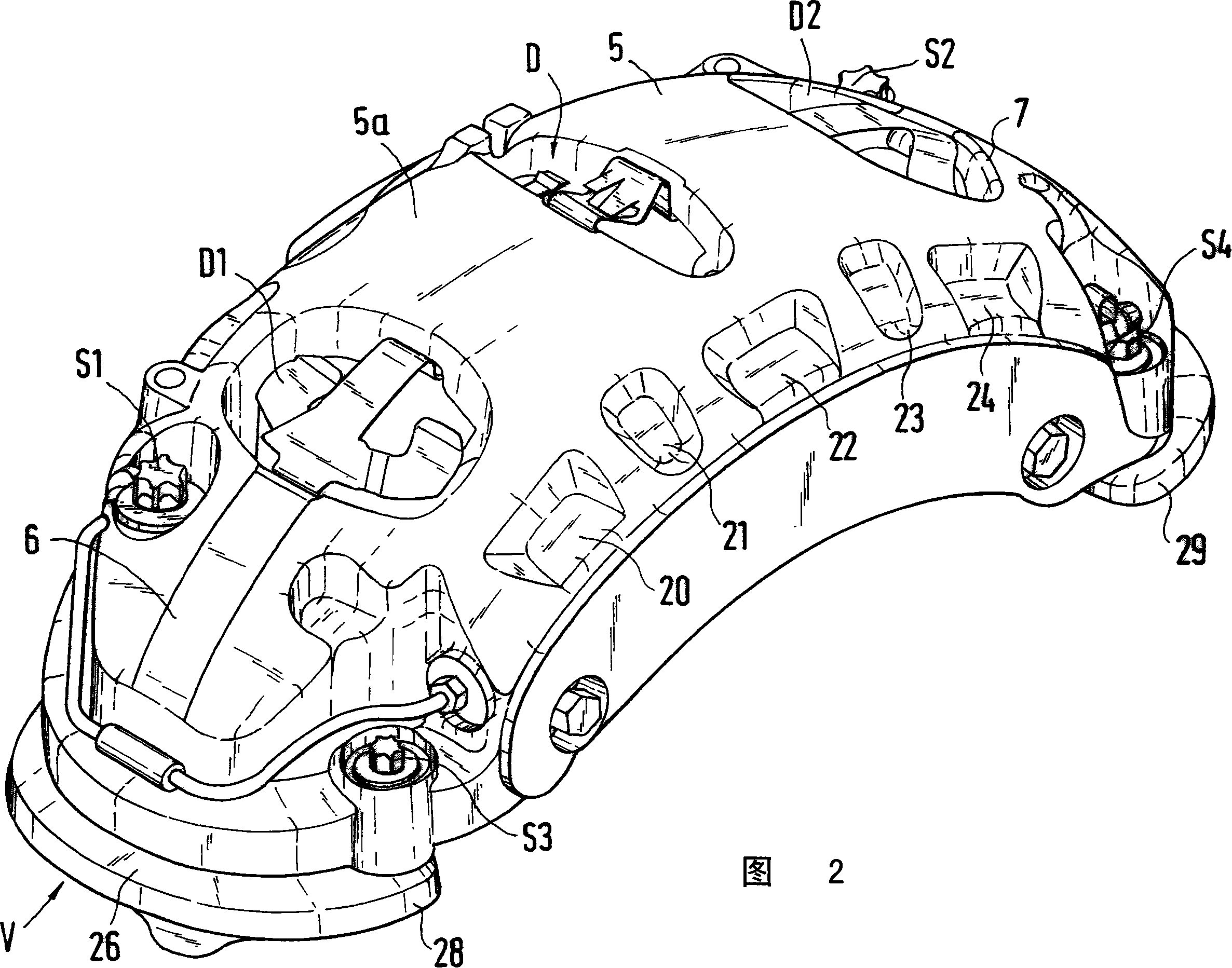

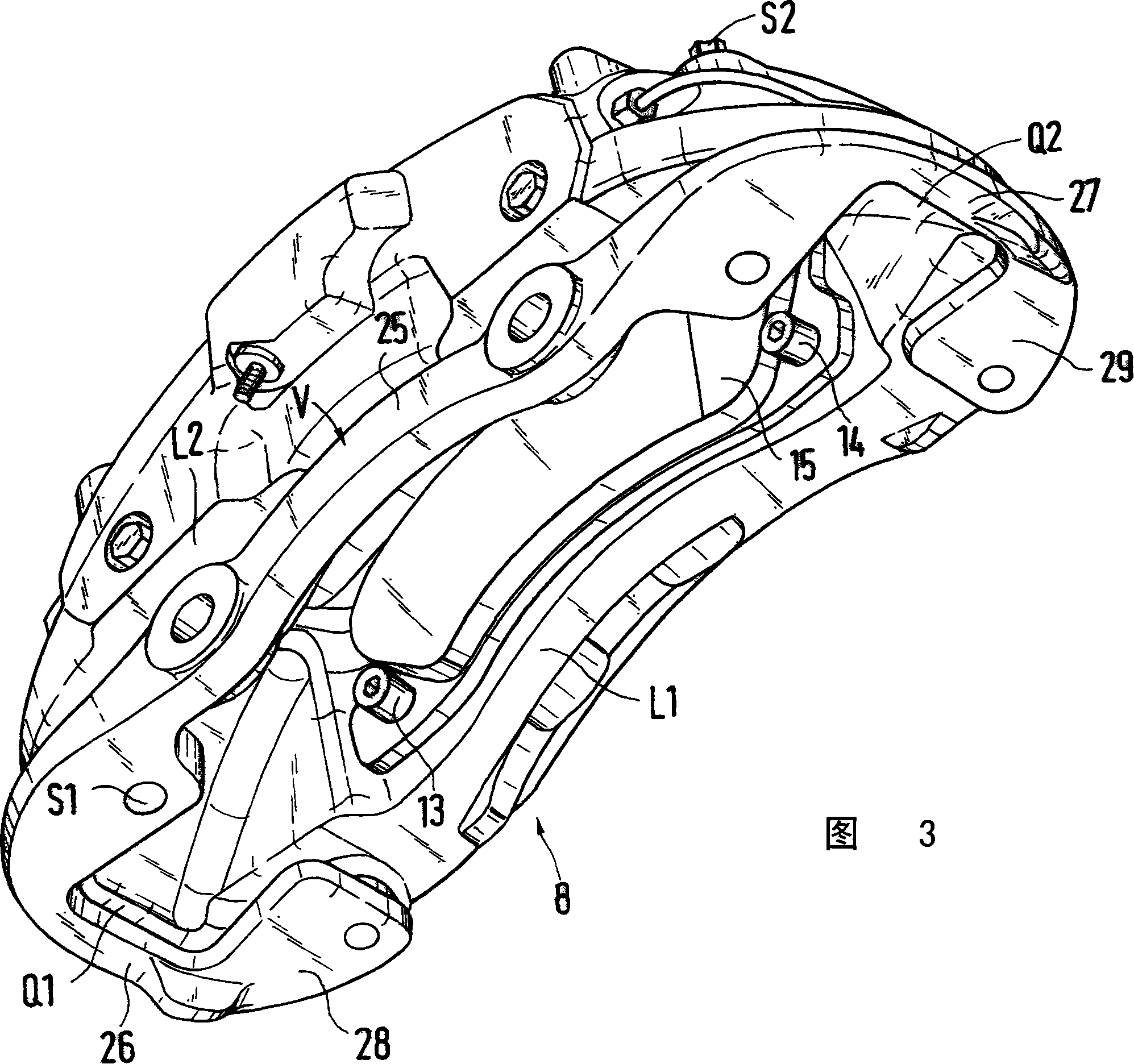

[0020] The brake caliper 1 comprises a housing with two caliper arms 2 and 3 which are arranged spaced apart from one another. The brake caliper arms 2 , 3 are connected to one another via a caliper bridge 5 , 5 a or 6 , 7 . They extend approximately half-arched across the brake caliper 1 and form a so-called supporting frame integrated at the edges with the free edges of the brake caliper arms 2 , 3 , which runs around the circumference and is designed to be closed. The supporting frame 8 integrated in the brake caliper 1 forms the longitudinal and transverse edges L1 , L2 and Q1 and Q2 . A reinforcing element V; V1 is connected to this supporting frame 8 , which supports the brake caliper 1 and is connected to the wheel carrier 12 or to such a component of the vehicle.

[0021] The brake caliper 1 is fixedly connected to the wheel carrier 12 or such components on the vehicle via bolts arranged in the fixing seats 10 , 11 , as shown in detail in FIG. 1 . Brake linings 15 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com