Air spring and multi-connecting-rod independent suspension

A technology of air springs and airbags, which is applied in the field of transportation, can solve the problems of high cost and large installation space, and achieve the effects of prolonging service life, reducing the probability of damage, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

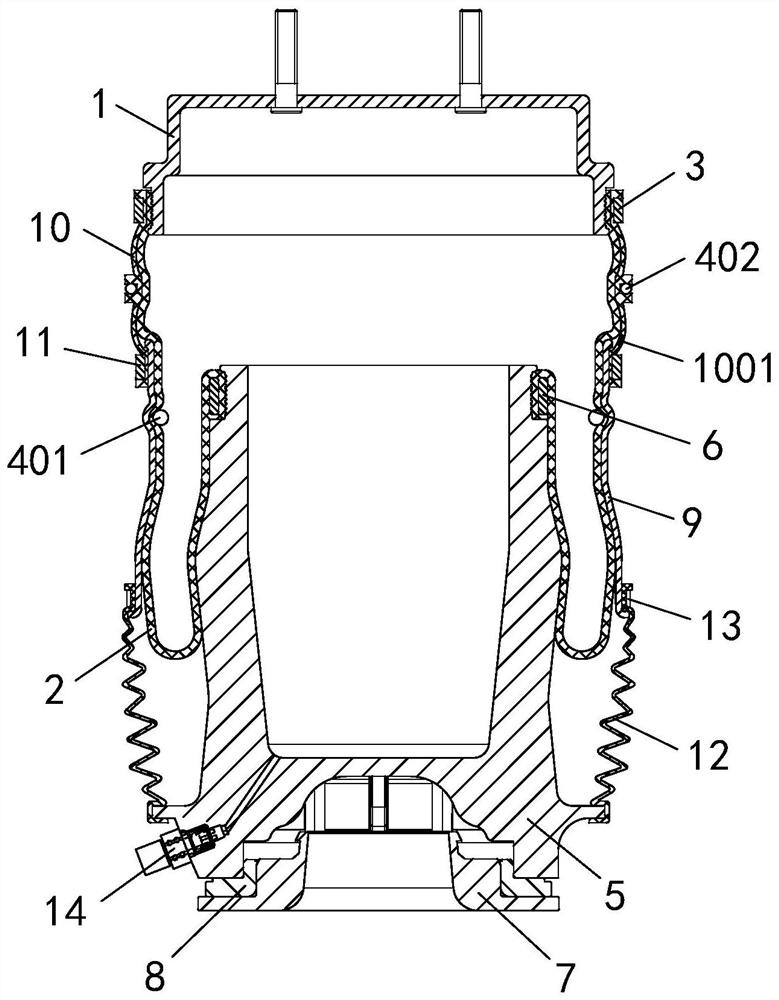

[0033] Embodiment 1: see figure 1 , image 3 , an air spring comprising:

[0034] upper cover 1;

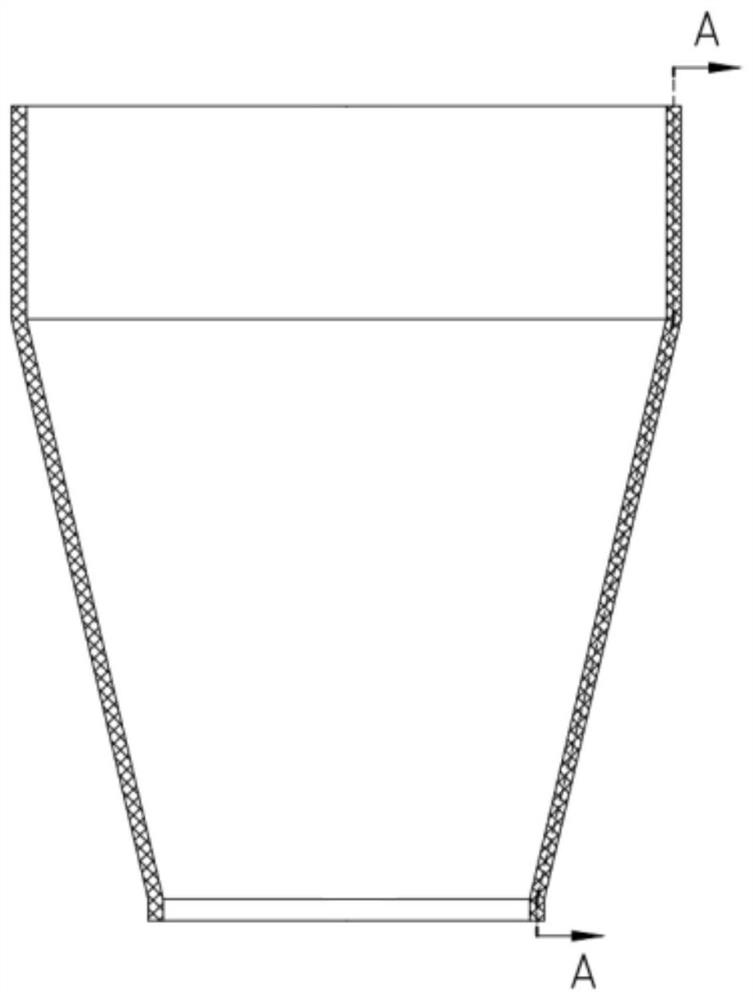

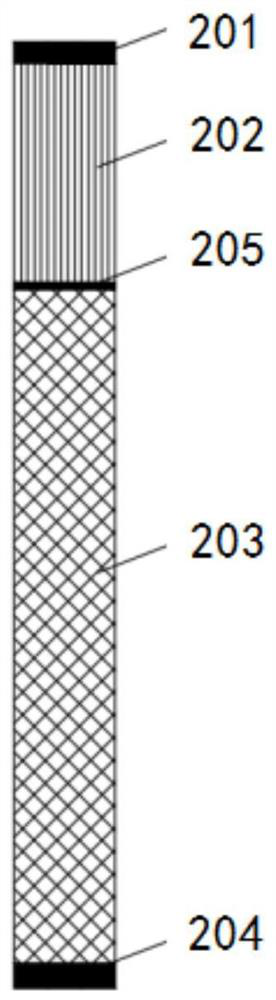

[0035] The airbag 2 is arranged under the upper cover 1, and the top of the airbag 2 (ie, the upper buckle end 201) is connected to the upper cover 1 through the first snap ring 3; the inner wall of the airbag 2 is provided with a first restraining ring 401, which divides the airbag 2 Two sections, the exposed part of the airbag in the upper section adopts two layers of along-line cords 202, and the other parts of the airbag adopt cross cords 203;

[0036] The piston 5 is located below the air bag 2, forms a sealed container with the upper cover 1 and the air bag 2, and the outer edge of the top end of the piston 5 is connected with the air bag 2 through the second snap ring 6;

[0037] The base 7 is arranged below the piston 5, and the upper end of the base 7 is connected with the piston 5;

[0038] The bearing 8 is located between the base 7 and the piston 5, and is connect...

Embodiment 2

[0051] Embodiment 2: An air spring. The difference from Embodiment 1 is that in this embodiment, the airbag is made of nylon wire and rubber vulcanized at a high temperature of 160°C, so that the nylon wire and rubber have chemically reacted and fused together. The body, the three-layer along-line cord on the exposed part of the upper airbag is made by parallel and along-line technology.

[0052] The above-mentioned air spring in this embodiment is mainly equipped with passenger cars with multi-link independent suspension, such as: all Mercedes-Benz E-class series, BMW 3 series and 5 series, FAW-Volkswagen Audi A4L and A6L, Passat of Shanghai Volkswagen and many models. The above-mentioned multi-link independent suspension is a suspension with high popularity.

Embodiment 3

[0053] Embodiment 3: An air spring. The difference from Embodiment 1 is that in this embodiment, the airbag is made of nylon thread and rubber vulcanized at a high temperature of 180°C, so that the nylon thread and rubber have chemically reacted and fused together. Body, the two-layer along-line cord of the exposed part of the airbag in the upper section is made by parallel and along-line technology.

[0054] The above-mentioned air spring in this embodiment is mainly equipped with passenger cars with multi-link independent suspension, such as: all Mercedes-Benz E-class series, BMW 3 series and 5 series, FAW-Volkswagen Audi A4L and A6L, Passat of Shanghai Volkswagen and many models. The above-mentioned multi-link independent suspension is a suspension with high popularity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com