Dividing and spiral-screening cart

A technology of spiral and sand sieving, which is applied in sieving, solid separation, and separation of solids from solids by air flow. Increase the screening effect and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

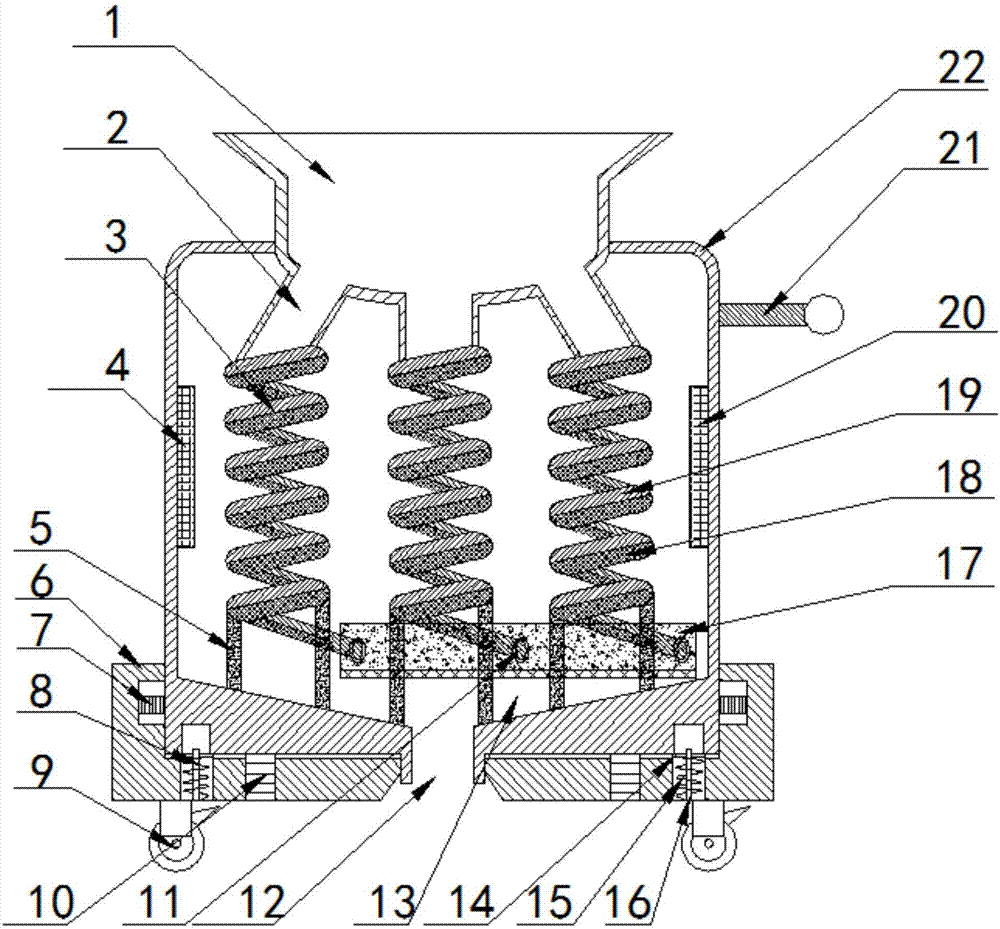

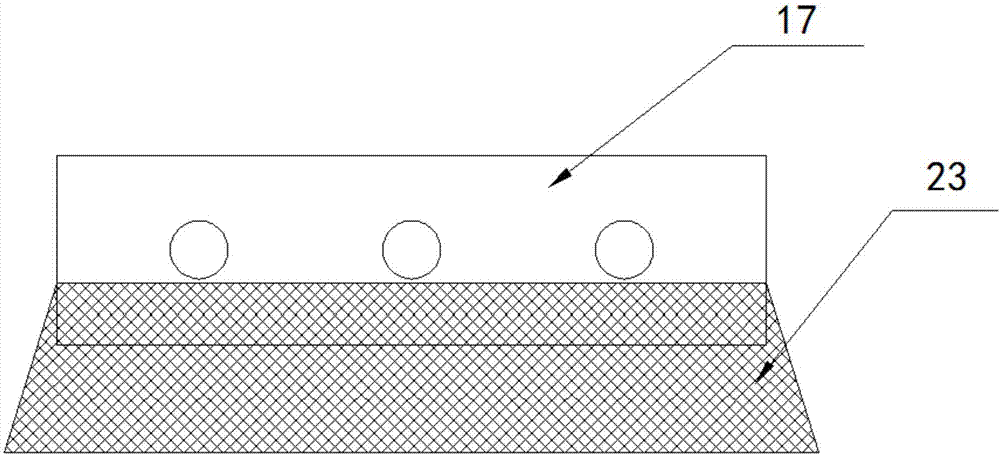

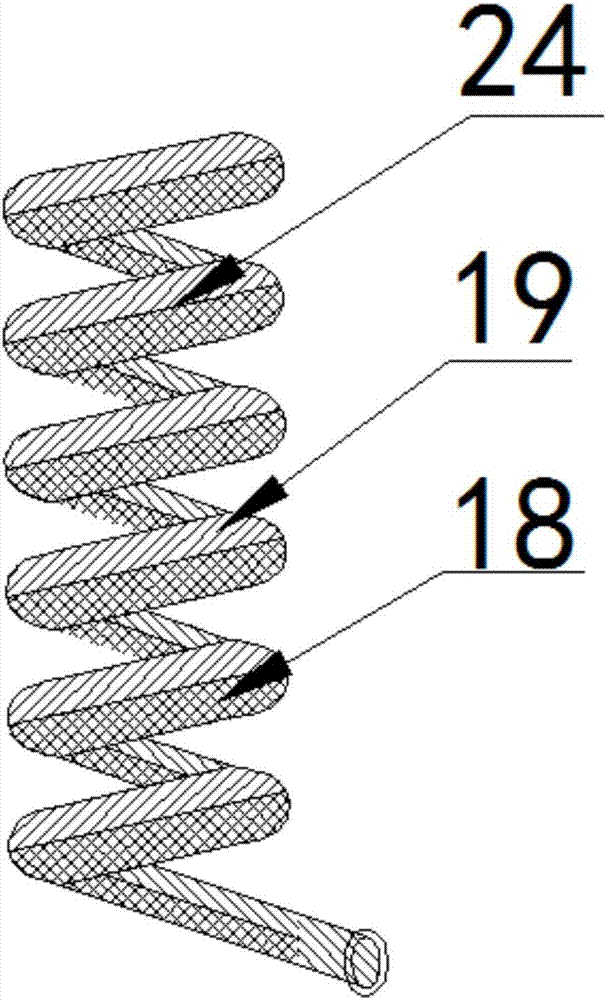

[0017] see Figure 1-3 , a diverting spiral sand sand trolley, comprising a feeding device 1, a diverting pipe 2, a spiral sand screening device 3, a drying device 4, a coarse sand collecting and screening device 17, a vibrating device 10, a heterosexual fixed support platform 6, and a housing 22 and universal wheel 9; the feeding device 1 is arranged on the top of the shell 22, and communicates with its inside, for putting sand to be screened; the bottom of the feeding device 1 is connected with three shunt pipes 2 connected together, the sand in the feeding device 1 is processed in batches to speed up the screening rate; the spiral sand screening device 3 is arranged below the shunt pipe 2, and is connected with the feeding device 1 through the shunt pipe 2 , for screening the sand that flows in; The spiral sand screening device 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com