Filling device for fireproof plugging material

A filling device and fireproof sealing technology, which is applied in the direction of solid materials, packaging, transportation and packaging, etc., can solve the problem that the tank cannot be filled, and achieve the effects of avoiding cavities, improving fullness, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

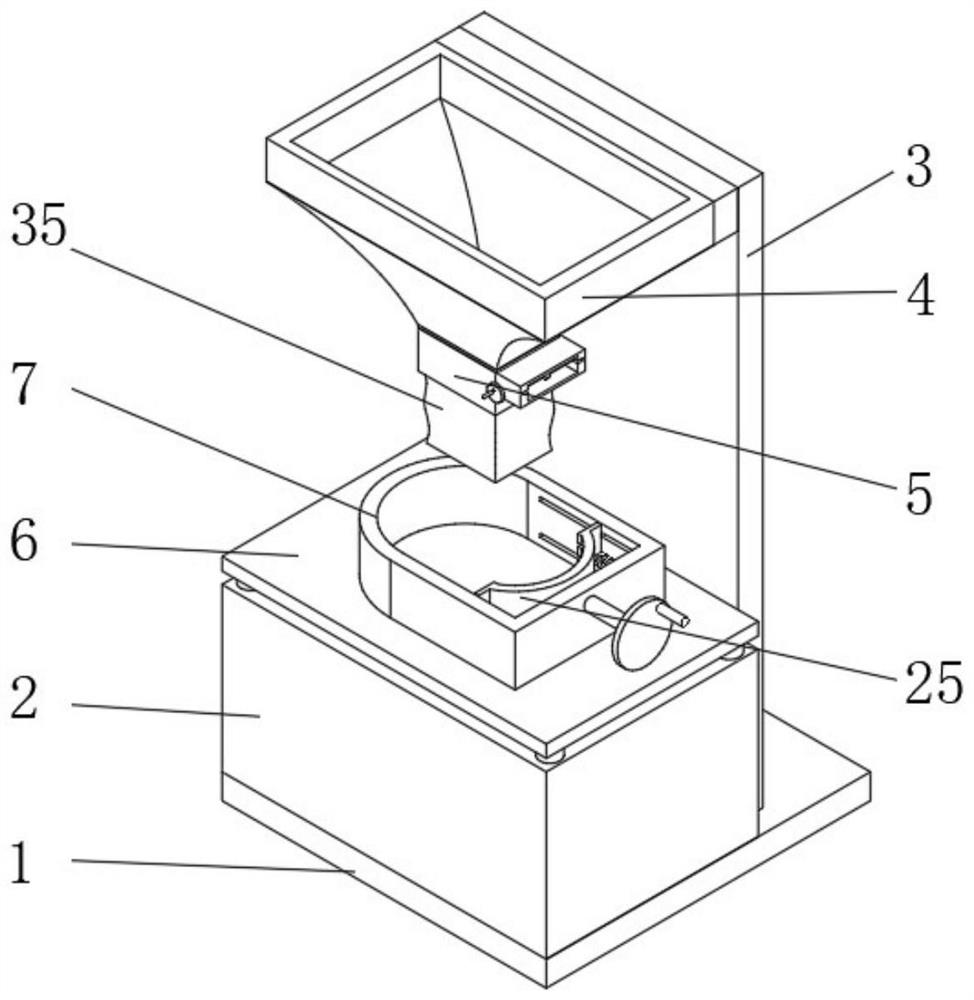

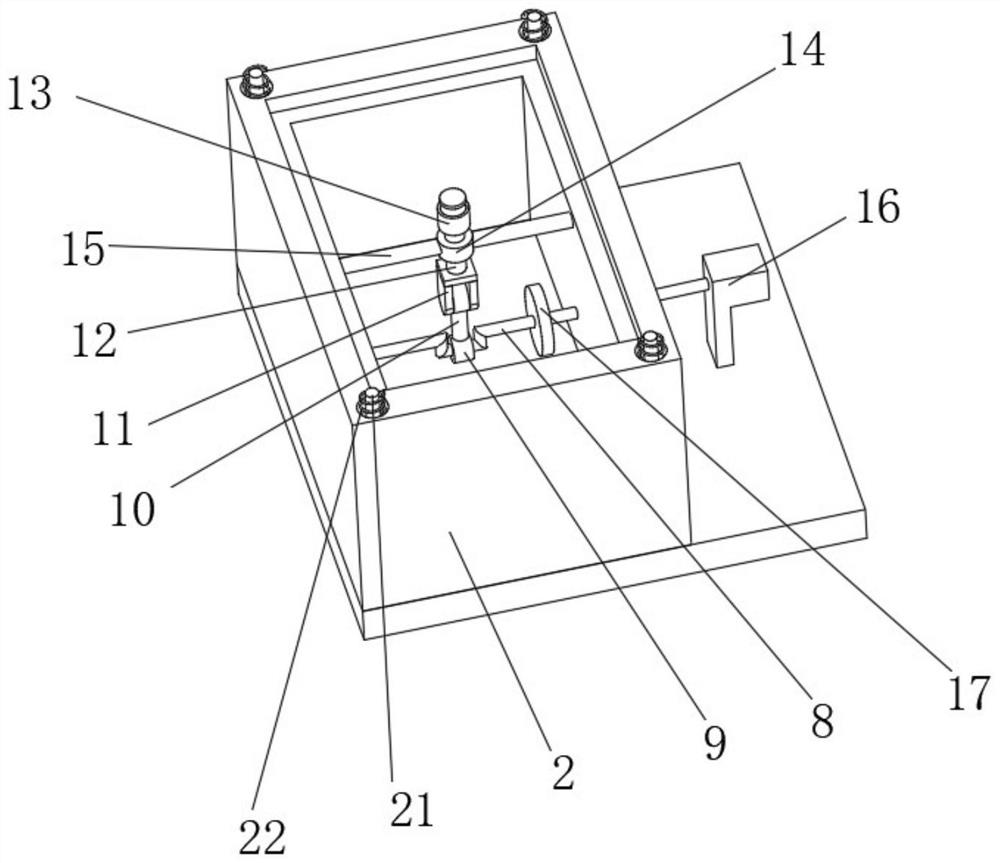

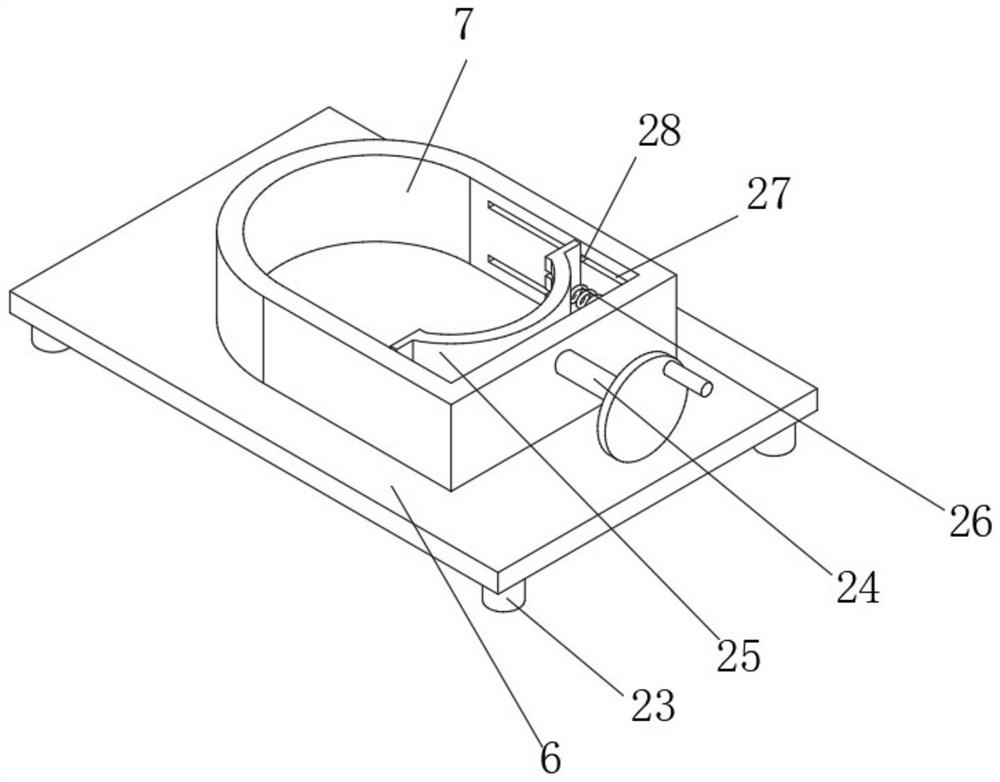

[0027] The embodiment of the invention discloses a filling device for fireproof sealing material, such as Figure 1-6 As shown, including the base 1, the top of the base 1 is fixedly connected with the power box 2, one side of the power box 2 is fixedly connected with the side plate 3, and the bottom end of the side plate 3 is fixedly connected with the top of the base 1, The top of the front of the side plate 3 is fixedly connected with the lower hopper 4, the bottom of the lower hopper 4 is fixedly connected with the connecting pipe 5, the bottom of the back of the lower hopper 4 is fixedly connected with the front of the side plate 3 through a stabilizing block, the top of the power box 2 A vibrating plate 6 is provided, the top of the vibrating plate 6 is fixedly connected with a fixture seat 7, the inner wall of the power box 2 is rotatably connected with a crankshaft 8, the middle part of the crankshaft 8 is rotatably sleeved with a casing 9, and the outer side of the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com