Long range big-push force permanent-magnet brushless linear DC motor

A DC motor and permanent magnet technology, applied in the direction of linear DC motor control, AC motor control, electric components, etc., can solve the problems of aggravating the saturation degree of the inner column magnetic flux density, increasing the leakage flux, increasing the stroke, etc., to achieve the guide Good magnetic properties, high resistivity, and the effect of reducing reverse electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

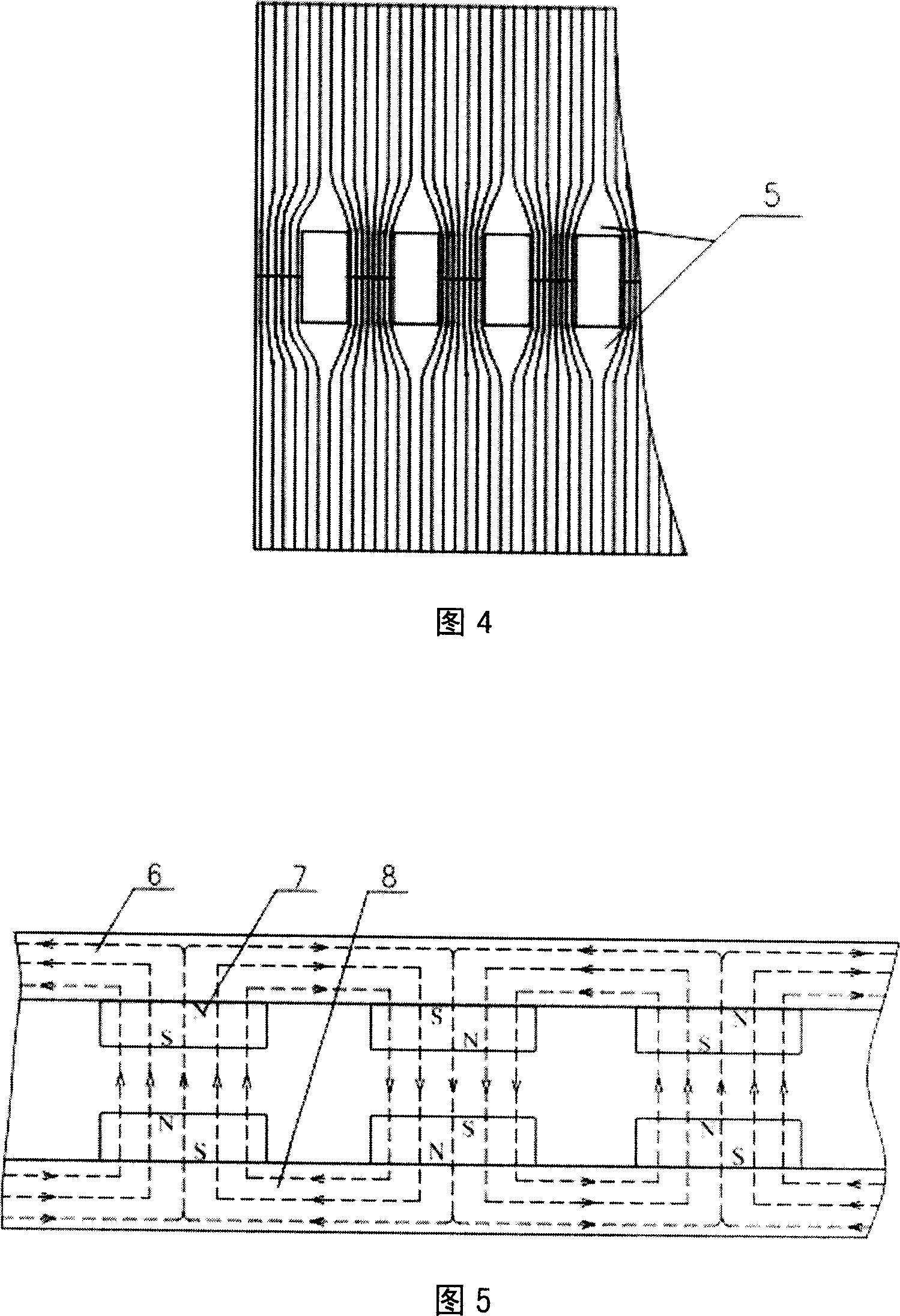

[0023] The driving principle of the long-stroke and high-thrust permanent magnet brushless linear DC motor of the present invention is shown in Figure 6. The wire is placed along the direction perpendicular to the magnetic field. When the wire is passed with current, the wire will be subjected to the electromagnetic force shown in the figure The effect of this electromagnetic force is the thrust of the present invention, and its magnitude can be obtained according to the formula F=NBIL, wherein N is the number of turns of the coil, B is the magnetic field strength, I is the coil current strength, and L is the single-turn coil in the magnetic field effective length in .

[0024] The invention uses a grating detection system to detect the displacement and speed of the motor mover. The specific principle is: the grating detection system outputs two square wave pulse signals with a phase difference of 90°, which are sent to the two QFP pins of the DSP after shaping, and then the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com