Control of long-stator linear motor coils of long-stator linear motor stator

A coil and stator technology is applied in the field of controlling multiple LLM coils of the LLM stator, which can solve the problems of high cost and large circuit technology cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

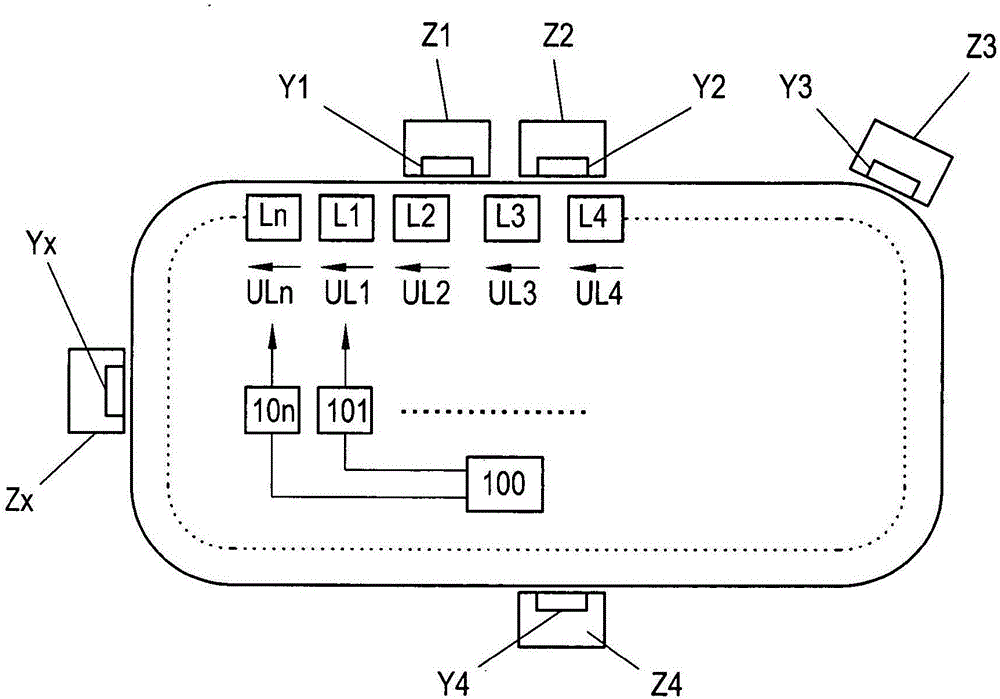

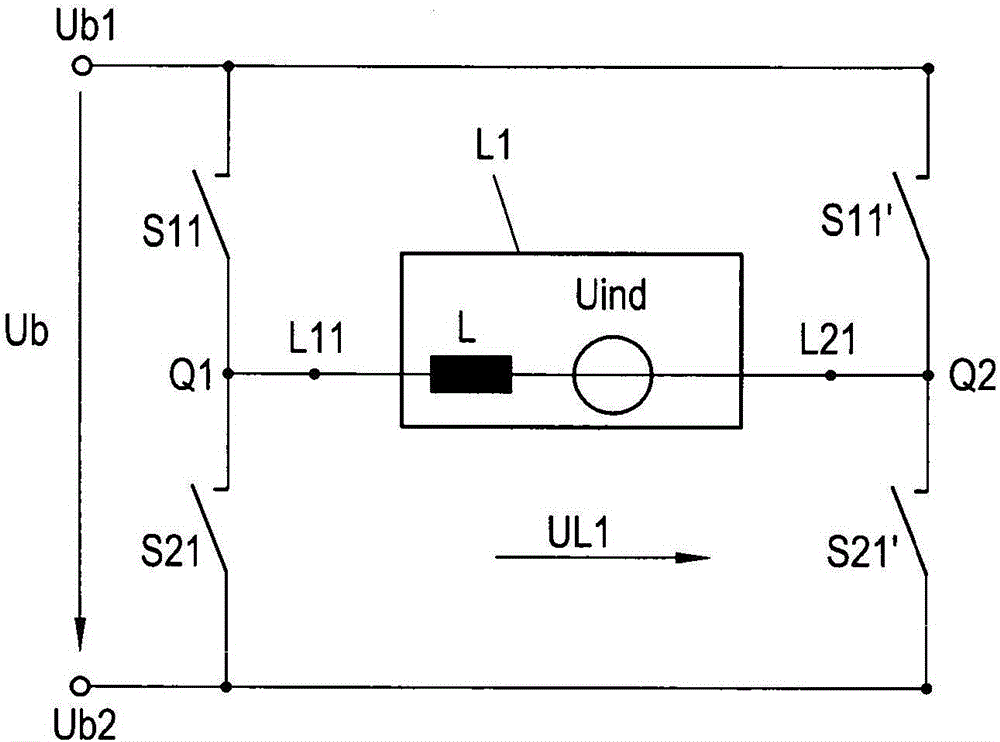

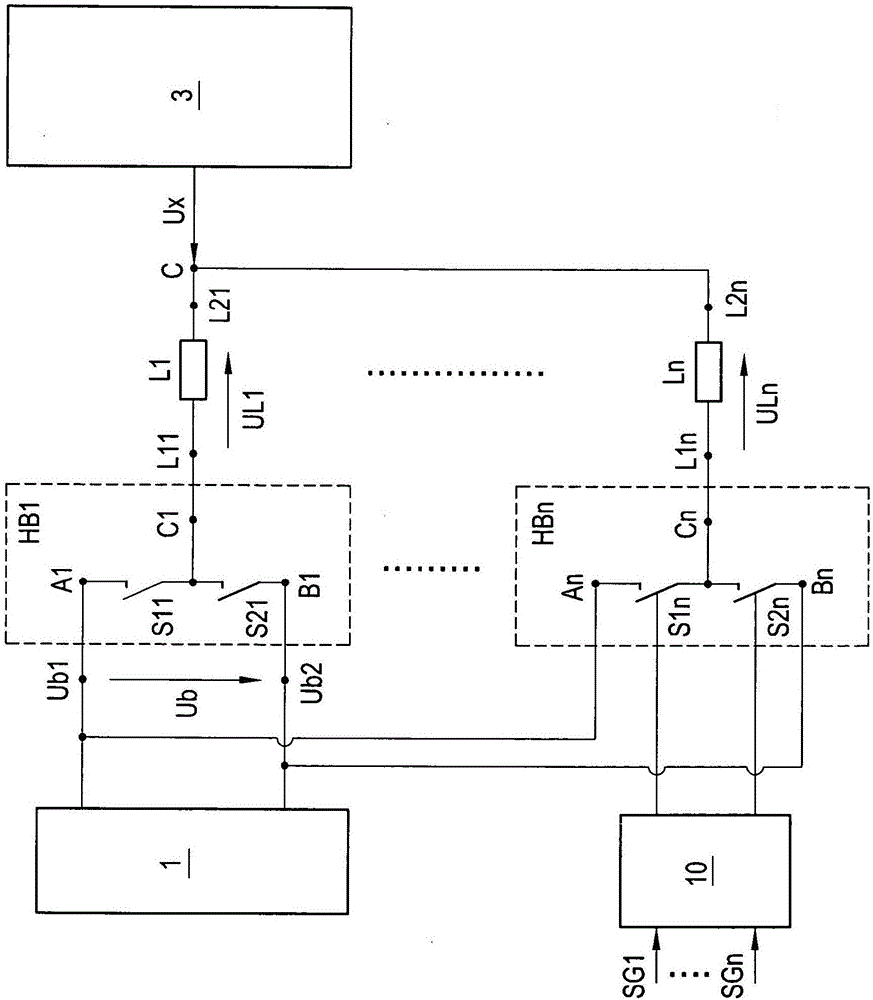

[0027]Figure 1 exemplarily shows a conveyor in the form of a long stator linear motor (LLM). The conveying device here consists of only one conveying section, although in practice a plurality of conveying sections are possible which are combined to form the conveying device, which may also not be formed in a closed track. The conveying device is embodied as an LLM, in which the conveying sections are each formed as part of a long stator of the LLM in a manner known per se. In this case, the transfer section can be further divided in a known manner, for example into several individual transfer sections in the form of a coil arrangement with a plurality of LLM coils. Along the conveying section, therefore, in the longitudinal direction, a plurality of electric LLM coils L1,...,Ln are arranged in a known manner, which LLM coils are connected to the field magnets Y1 on the conveying units Z1...Zx , ..., Yn cooperate. In a likewise known manner, the coil voltages UL1 , . . . , UL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com