Well cementation method suitable for shale gas well refracturing

A technology for repeated fracturing and shale gas wells, which is applied in wellbore/well components, earthwork drilling and production, drilling equipment, etc. It can solve the problems of high leakage risk, difficult casing centering, and difficult casing running, etc., to achieve guarantee Plugging effect, ensuring construction steps, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

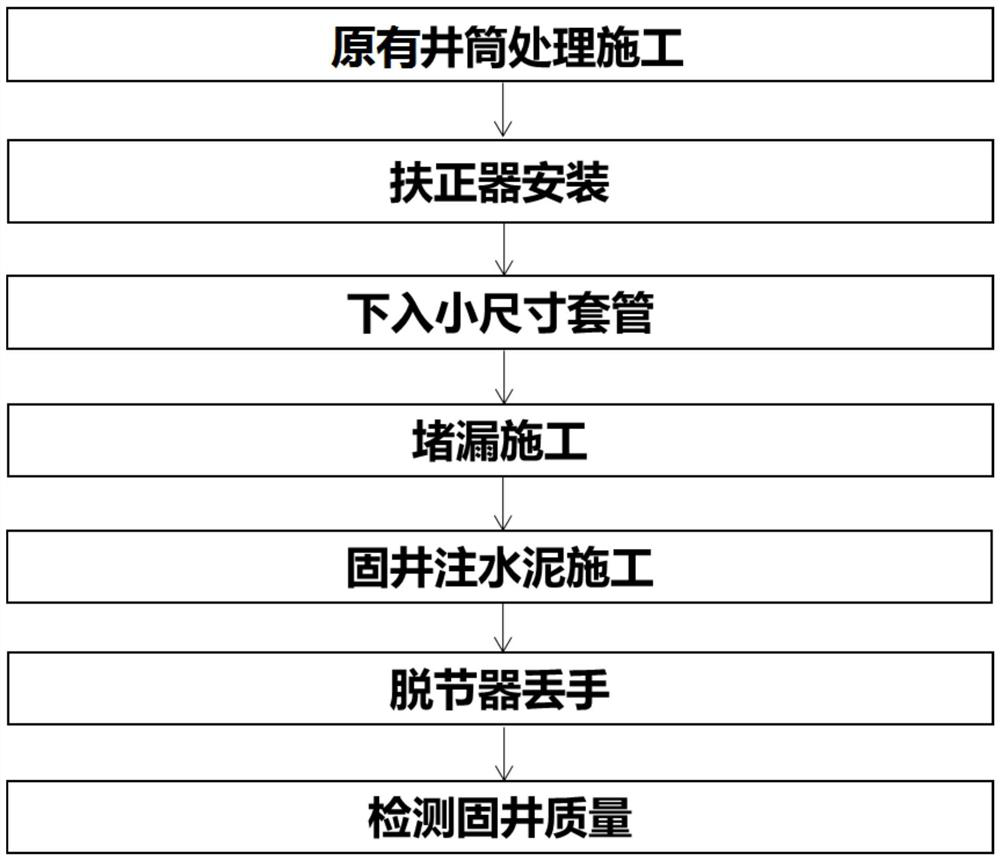

[0046] A method suitable for repeated fracturing and cementing of shale gas wells, such as figure 1 shown, including the following steps:

[0047] (1) For the construction of the original wellbore treatment, the original wellbore shall be drilled with the drilling tool. The stiffness of the drilling tool assembly shall be greater than that of the casing, and the outer diameter of the drilling tool shall not be less than 112mm; Short-range tripping and reaming are performed in the blockage and stuck sections of the drilling to ensure the smoothness of the wellbore; then reinject 2% potassium chloride solution into the original wellbore to reduce the formation loss to 12m 3 / h, so that there is an outlet for the workover operation cycle to ensure the safety of the well control; at the same time, the bottom hole pressure is raised to above 22MPa, so that the plugging agent can form a support in the near wellbore area to ensure the plugging effect; the workover rig simulates solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com