Secondary well cementing technique and secondary well cementing device by liner pipe

A cementing and lining technology, which is applied to the valve device, drilling pipe, casing and other directions of the wellbore/well, can solve the problems of complex operation, low reliability and high cost of process equipment, and achieves simple process and high reliability. 、Ensure the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

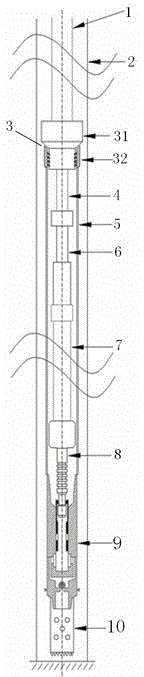

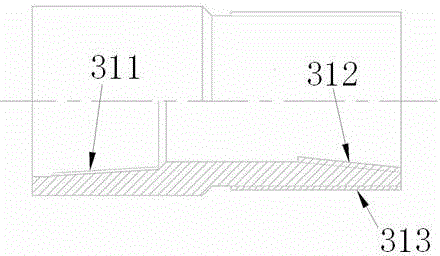

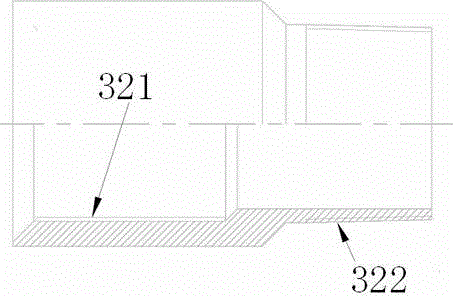

[0043] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a liner secondary cementing device, which is mainly composed of a delivery pipe string, an inner pipe string and an outer pipe string arranged inside the casing 2 . The delivery string is mainly composed of the upper joint of the hand-off joint and the lower joint of the hand-out joint connected with the oil pipe I thread, and the upper joint of the hand-out joint is connected with the lower joint of the hand-out joint through the left-hand thread.

[0044] The inner tubing string is mainly composed of a tubing pup joint, a tubing length compensator, tubing II and an intubation tube which are sequentially connected with the threaded joint of the upper joint of the drop-off joint.

[0045] The outer pipe string is mainly composed of a liner, an intubation cementing valve and a sawtooth screen that are sequentially connected with the lower joint of the drop joint.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com