Cementing device for thin interlayer adjustment wells

A kind of interlayer and cementing technology, which is applied in the direction of wellbore/well components, sealing/isolation, earthwork drilling and production, etc. It can solve the problems affecting perforation, oil production, restricted use, and inconvenient transportation, so as to improve the life of oil wells and production rate, preventing fluid phase channeling, and ensuring the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

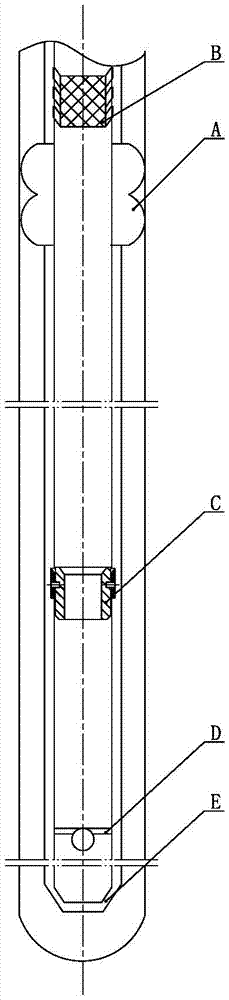

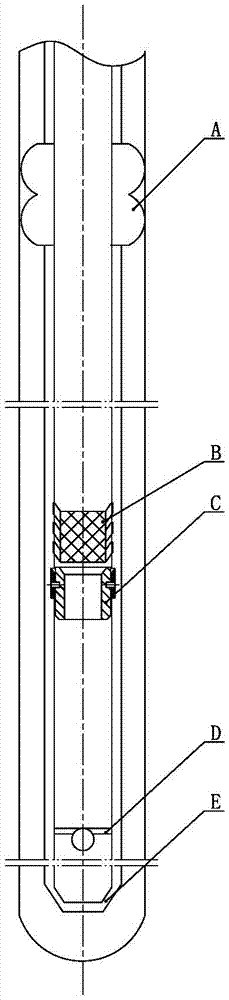

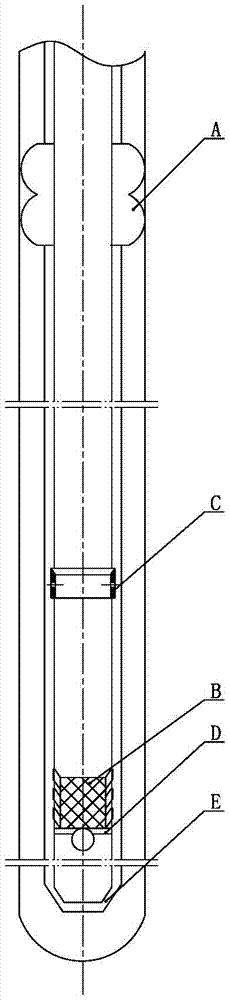

[0049] Specific embodiment one: the well depth is 1840m, the oil top is 1500m, the oil bottom is 1800m, and the design cement return height is 1200m; the water injection pressure of the water injection well is above 19MPa, overflow occurs during the drilling process, and the drilling fluid density is 1.25g / cm The interlayer is located at 1608.07-1611.03m, the well diameter is regular, and it belongs to the well section of the mudstone layer; the nominal diameter of the casing is 5½", and the process of the present invention is used for cementing. It is about 23m away from the bottom of the oil layer, the depth below the hoop is 1832.00m, and the distance between the hoop and the shoe is 11m. It is determined that the working pressure of the packer is 9MPa, the setting pressure of the packer is 12MPa, and the opening pressure of the annular pressure compensator The value is 22.6MPa, and the impact pressure value after the rubber stopper stops is 10.5MPa.

[0050] Step (4) Use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com