Cement-free well cementation method for horizontal section of horizontal well

A technology for horizontal section and horizontal well, which is applied to the field of cement-free cementing in the horizontal section of horizontal wells, can solve the problems of complex cementing process and poor cementing quality, and achieve the effects of simplifying construction technology, saving completion costs and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

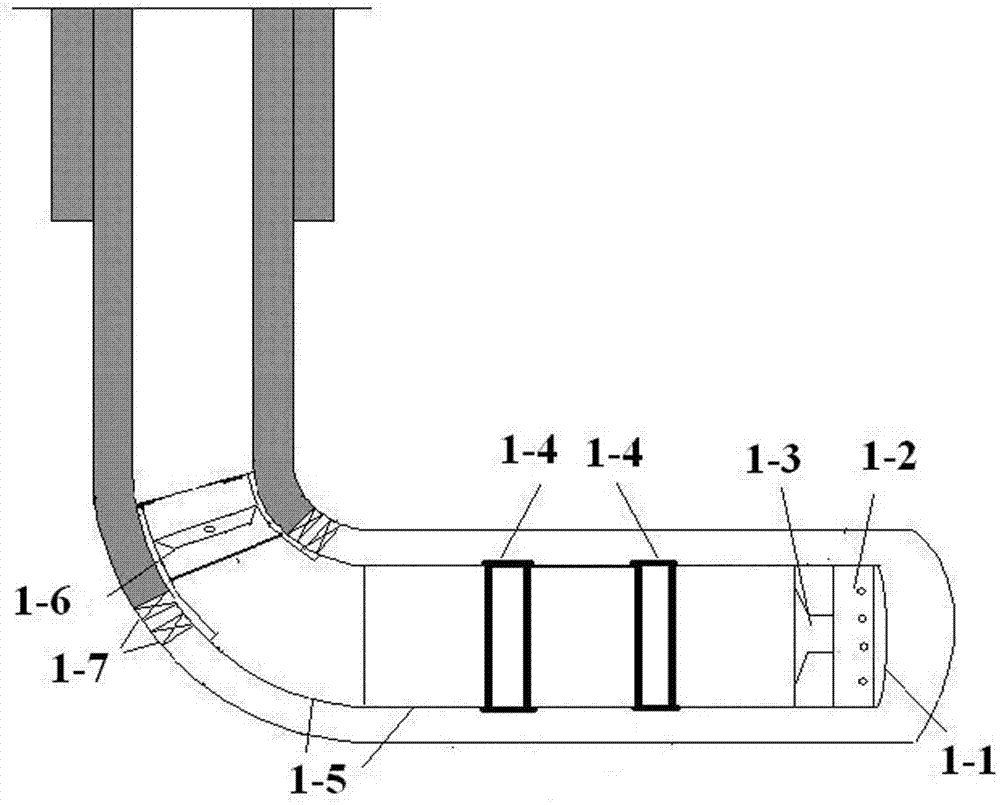

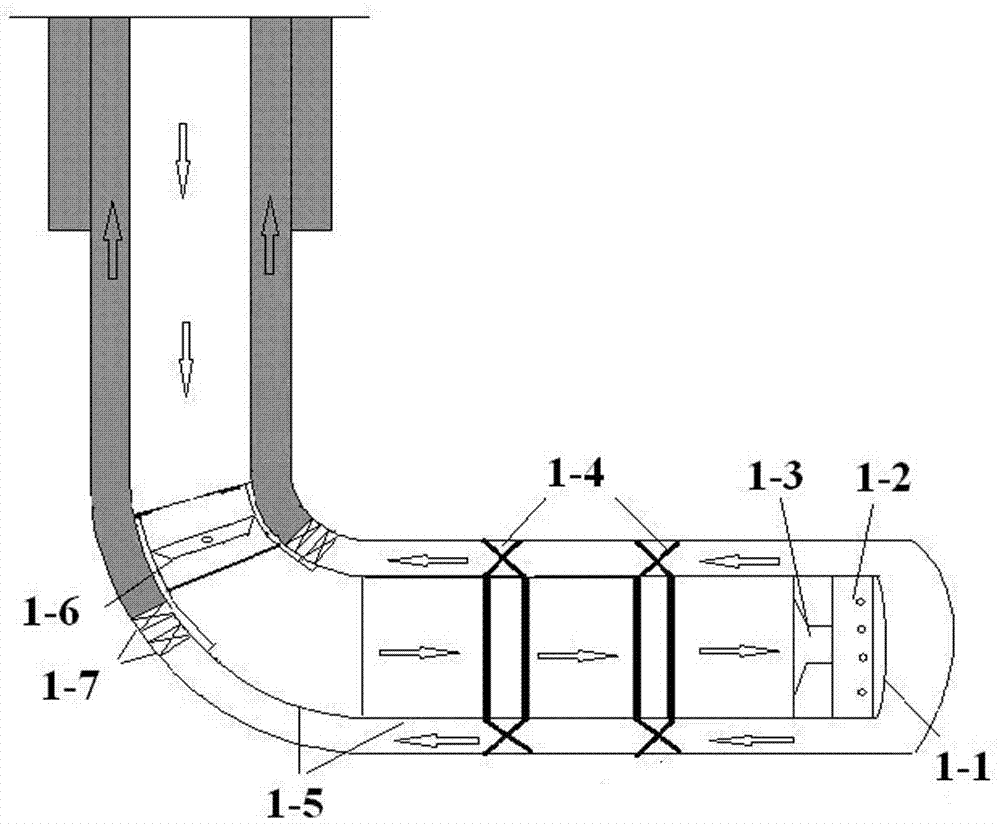

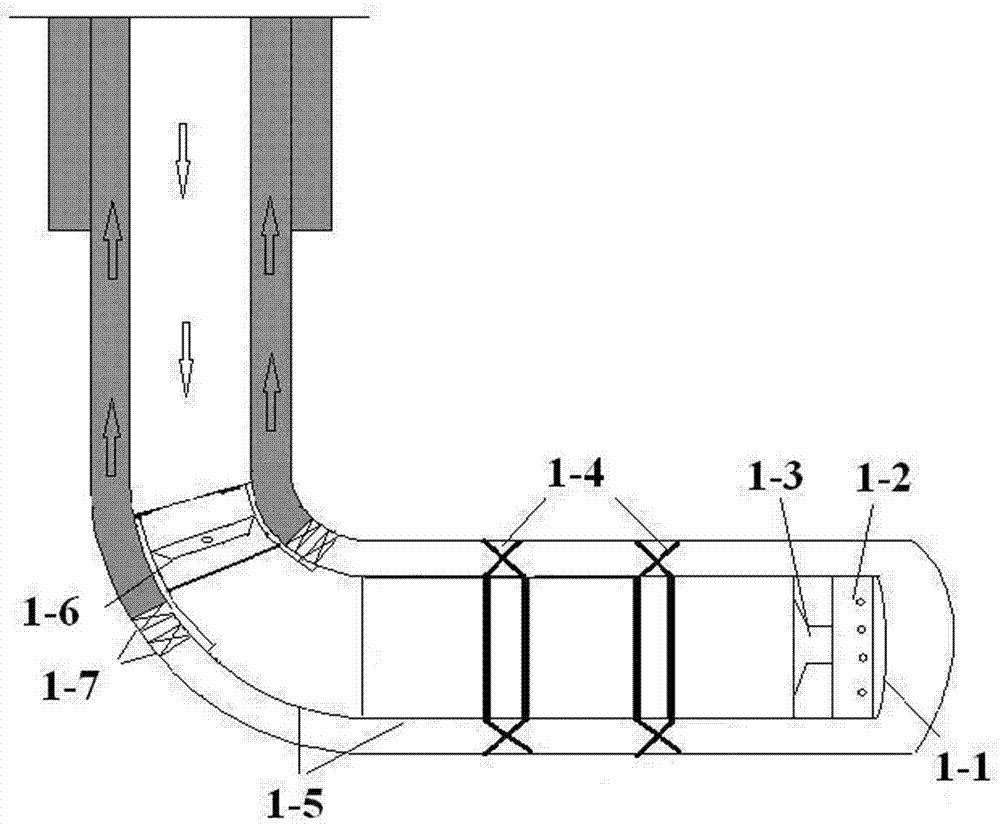

[0040] The completion method will be described in detail below by taking the plug-free tool (Chinese patent ZL201120157427.4) as the casing fixing tool as an example.

[0041] Form adopted figure 1 The structural form shown. Firstly, construct the structural pipe string of the well completion system with casing fixing tools in the horizontal section: from bottom to top to the wellhead, guide shoes 1-1, well flushing valves 1-2, ball seat sliding sleeves 1-3, and casing 1 are arranged sequentially. -4. Casing fixing tools 1-5 and plug-free tools. The plug-free tools mainly include salvage inner casing 1-6 and outer packer 1-7. During the running of the pipe string, the casing fixing tools 1-5 are closed, which does not affect the running of the pipe string. The constructed pipe string is lowered to the designated position of the oil and gas well for mud circulation. Expansion-sealed casing fixing device, which effectively fixes the casing and the well wall, establishes such ...

Embodiment 2

[0043] If the graded hoop is used as the top cementing tool, the steps of the well completion method are basically similar to those in Embodiment 1. The difference is that in the completion system with casing fixing tools in the constructed horizontal section, the plug-free position of the structural pipe string is replaced by a graded hoop. After the casing is lowered to the designed well depth, the pump is turned on to suppress the pressure at 5-10-12 MPa, and the pressure is stabilized for 3-5 minutes each, and the outer packer is expanded and sealed. Continue to suppress the pressure to 18MPa, and open the differential pressure grading hoop; first, the small displacement cycle of the single valve is more than one week, and after the mud circulation is normal, the large displacement cycle is normal; the cementing operation is carried out, and the cement truck is bumped (attention when the replacement is completed) Check the backflow, if there is backflow, add 2-3MPa to the ...

Embodiment 3

[0046] A self-expandable packer that can expand when encountering oil or water is used as a casing fixing tool. The packer consists of a base pipe and a rubber sleeve made of oil- or water-swellable rubber. It can be connected in series in the casing according to certain rules, and seal off the water layer and support the fixed casing after expanding downhole. It is also possible to vulcanize the rubber on the outer wall of the casing that can expand when encountering oil or water. After the rubber expands, it replaces the well cementing and is used to support and fix the casing.

[0047] The following examples for casing anchors include

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com