Delayed coagulation well cementation method of high-pressure gas underground gas storage wells

A technology for delaying solidification and gas storage wells, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve problems such as aging gas storage wells, difficult cleaning, accidents, etc., to ensure the quality of cementing, ensure safety performance, and ensure The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

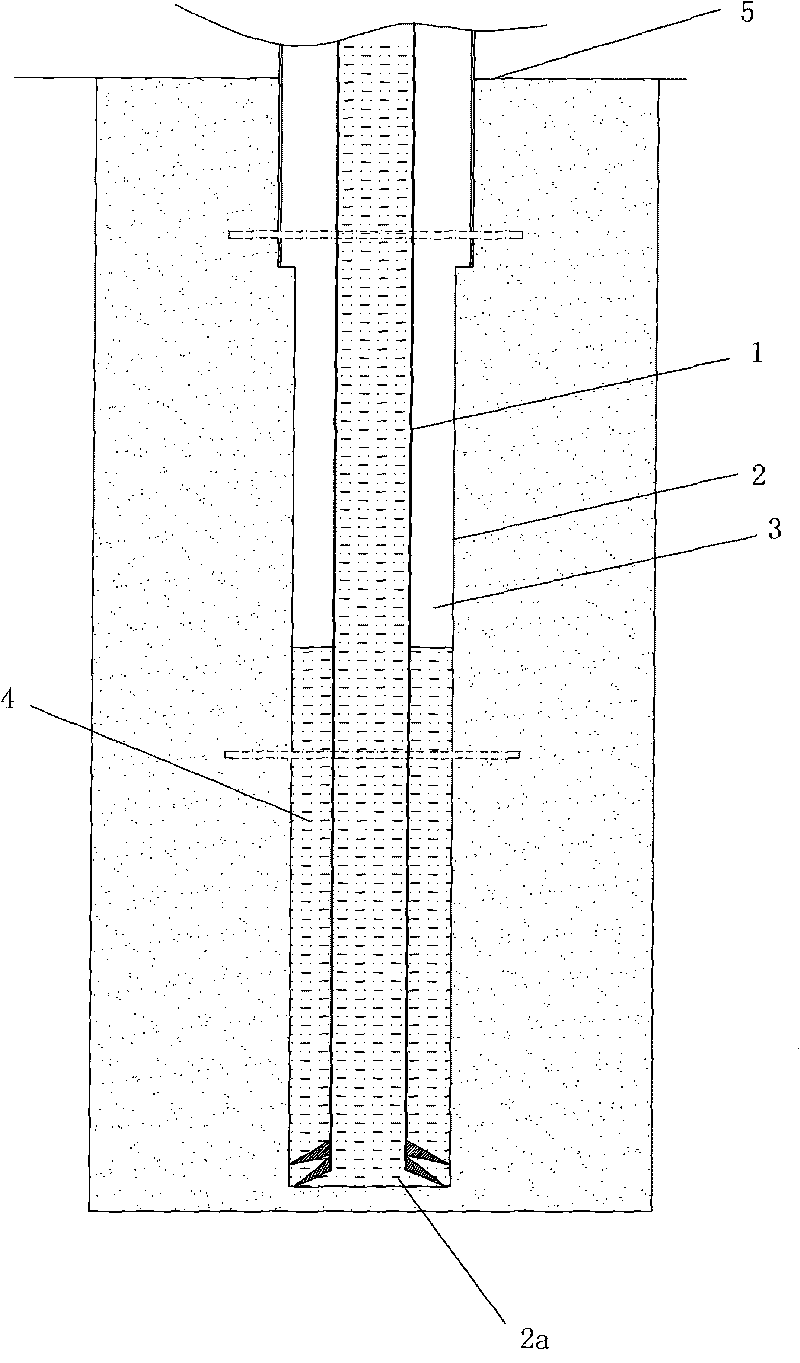

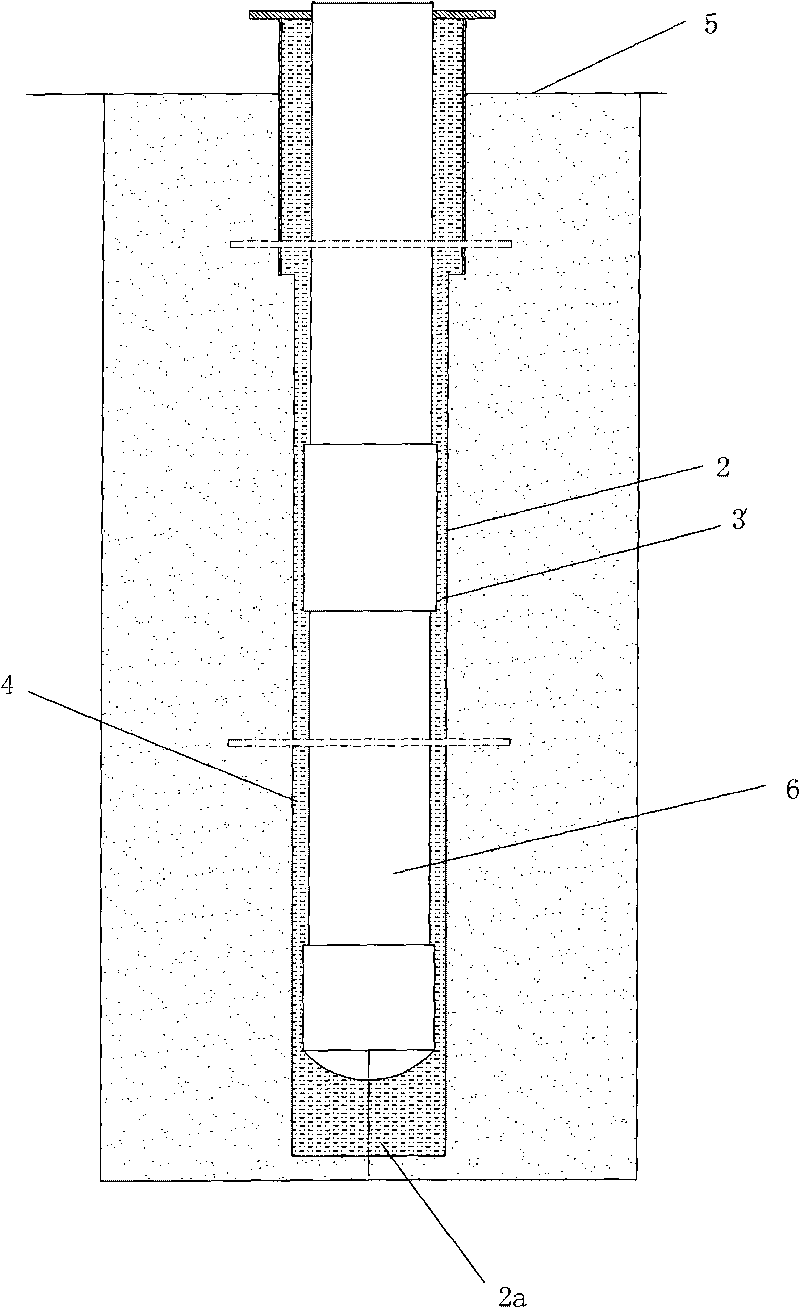

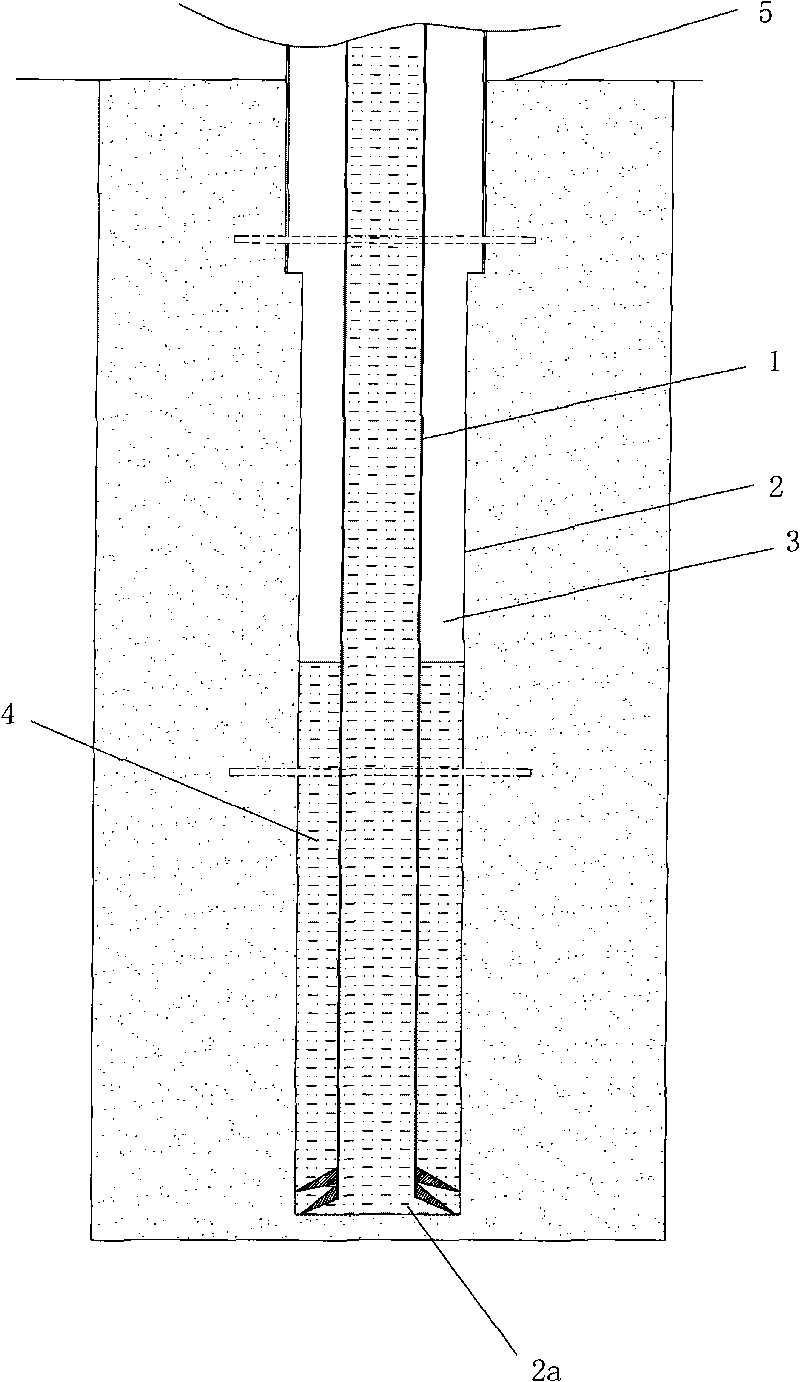

[0028] figure 1 and figure 2 Shown, a kind of embodiment of the present invention is: the delayed solidification cementing well method of high-pressure gas underground gas storage well, and its concrete steps are:

[0029] A, Drilling: Drill out the shaft 2 of the gas storage well with the drill bit at the front end of the drilling rod 1;

[0030] B. Grouting Connect the upper port of the inner cavity of the drill pipe 1 to the mud pump, and through the mud pump and the inner cavity of the drill pipe 1 to the bottom 2a of the wellbore and the annular space 3 between the outer wall of the drill pipe 1 and the wall of the wellbore 2, from Slowly inject the retarded cement slurry 4 from bottom to top until the retarded cement slurry 4 fills the annular space 3 and overflows the ground 5;

[0031] C. Installation of the well storage device Pull out the drill pipe 1, sink the cylindrical gas storage well device 6 with a diameter larger than the drill pipe into the well shaft 2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com