Well cementation method for controlling hydration heat of cement paste and improving well cementation quality

A technology of cement slurry and heat of hydration, applied in chemical instruments and methods, wellbore/well components, earthwork drilling and production, etc., can solve the problem of uncertain cementing technology and difficulty in matching the cement slurry system with geological and engineering conditions Control and other issues to achieve the effect of promoting cementing technology, ensuring sustainable development, and reducing the risk of poor cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

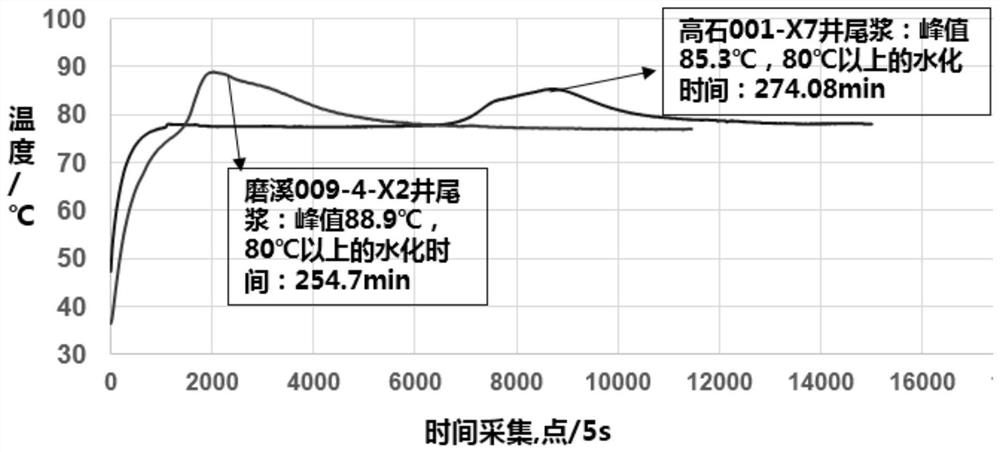

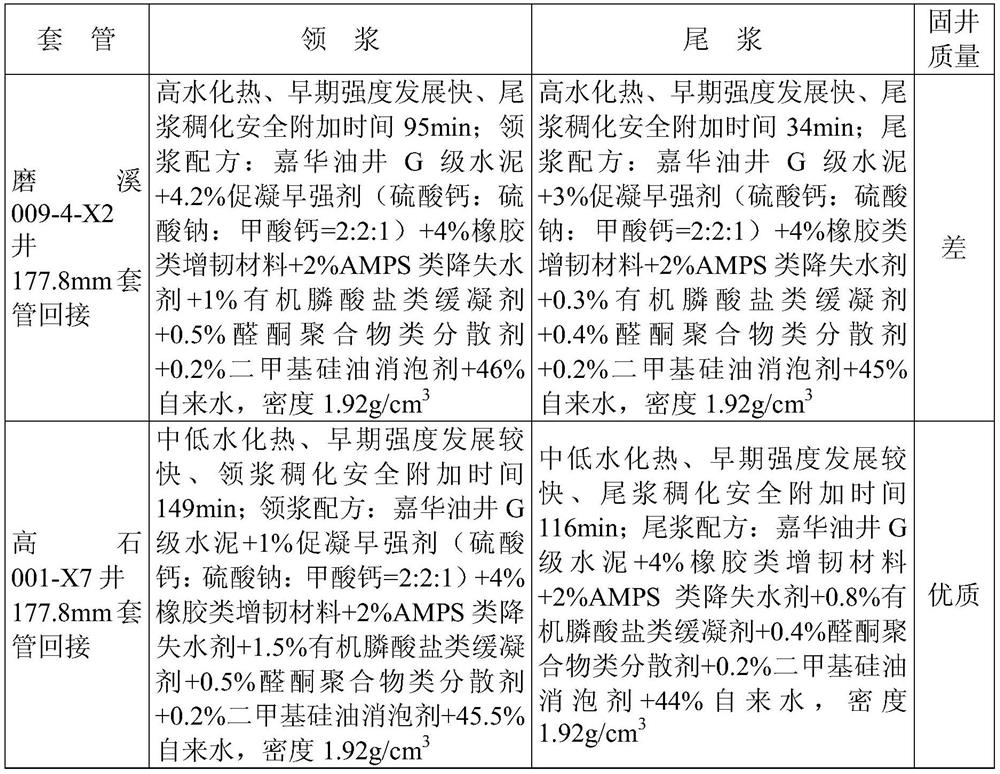

[0047]This embodiment provides a method for cementing a purely overlapping section well. Since it is impossible to use different cement slurries for the same well, this embodiment uses different cement slurries for two similar wells. Cementing treatment and comparison of cementing quality, Moxi 009-4-X2 well and Gaoshi 001-X7 well are both 177.8mm casing tiebacks, that is, pure overlap section. Among them, Moxi 009-4-X2 well uses conventional cement slurry, and Gaoshi 001-X7 well uses cement slurry that controls the heat of hydration. The specific control is to reduce the degree of hydration heat release of cement slurry and reduce cement The way to reduce the hydration heat release rate of the slurry is to reduce the amount of accelerator and early strength agent in the cement slurry to reduce the peak of the hydration heat release of the cement slurry, while increasing the amount of retarder added to extend the cement slurry The thickening safety additional time can reduce the pea...

Embodiment 2

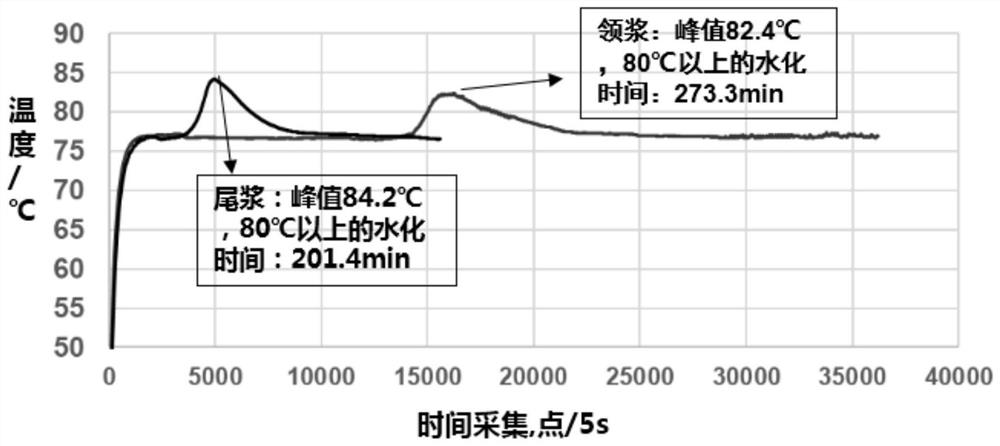

[0054]This embodiment provides a method for cementing a short overlap section well, which is to cement the Moxi 008-X23 well (177.8mm liner), that is, the short overlap section, without allowing tail slurry to enter the overlap section.

[0055]The Moxi 008-X23 well uses cement slurry to control the heat of hydration. The specific control is:

[0056]Lead slurry: Compared with tailing slurry, use a lower amount of accelerator and early strength agent to reduce the peak hydration heat release of cement slurry; compared to tail slurry, use a higher amount of retarder to extend the thickening time to reach cement The additional time required for slurry thickening safety reduces the peak and rate of hydration heat release of cement slurry;

[0057]Tailing slurry: Compared with the leading slurry, the use of a higher accelerator and early strength agent content increases the peak hydration heat release of the cement slurry; compared to the leading slurry, the use of a lower retarder content short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com