A suspended cement plug suitable for coiled tubing operations and its application method

A technology of cement plug and oil well cement, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., and can solve the problems of low anti-pollution ability and high cost of cement slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A suspended cement plug suitable for coiled tubing operations, the cement plug is divided into three parts, and each part includes the following components according to the mass ratio:

[0021] Reservoir cement plug formula: G-grade high sulfate-resistant oil well cement plus 1.2% dispersant plus 1.3% fluid loss reducer plus 6% micro-silicon plus 0.15% retarder, the water-cement ratio is 0.45;

[0022] Middle layer spacer formula: clear water, 0.5% polyacrylamide aqueous solution should be used 500m below the surface cement plug contact surface, and the 0.5% polyacrylamide aqueous solution should be prepared 4 hours in advance;

[0023] Surface cement plug formula: G-grade high sulfate-resistant oil well cement plus 1% dispersant plus 1% fluid loss reducer plus 0.05% retarder, and the water-cement ratio is 0.45.

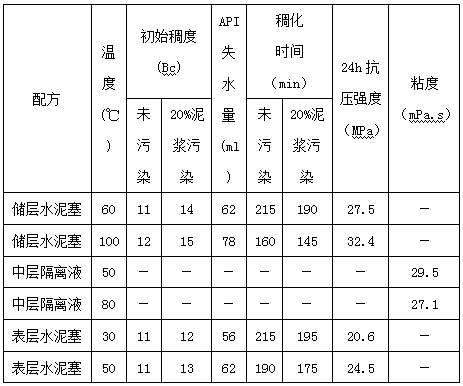

[0024] The related properties of cement slurry and spacer fluid are carried out according to the requirements of GB / T19139-2003 "Oil Well Cement Test Method" ...

Embodiment 2

[0030] A suspended cement plug suitable for coiled tubing operations, the cement plug is divided into three parts, and each part includes the following components according to the mass ratio:

[0031] Reservoir cement plug formula: G-grade high sulfate-resistant oil well cement plus 1.4% dispersant plus 1.5% fluid loss reducer plus 8% micro-silicon plus 0.45% retarder, the water-cement ratio is 0.45;

[0032] Middle layer spacer formula: clear water, 0.5% polyacrylamide aqueous solution should be used 500m below the surface cement plug contact surface, and the 0.5% polyacrylamide aqueous solution should be prepared 4 hours in advance;

[0033] Surface cement plug formula: G-grade high sulfate-resistant oil well cement plus 1% dispersant plus 1% fluid loss reducer plus 0.1% retarder, and the water-cement ratio is 0.45.

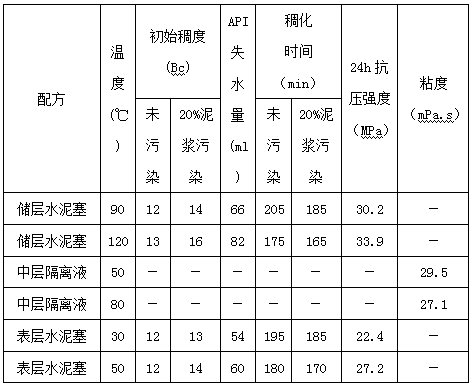

[0034] The related properties of cement slurry and spacer fluid are carried out according to the requirements of GB / T19139-2003 "Oil Well Cement Test Method" a...

Embodiment 3

[0040] A suspended cement plug suitable for coiled tubing operations, the cement plug is divided into three parts, and each part includes the following components according to the mass ratio:

[0041] Reservoir cement plug formula: G-grade high sulfate-resistant oil well cement plus 1.5% dispersant plus 1.6% fluid loss reducer plus 8% micro-silicon plus 0.35% retarder plus 35% silica sand (add at 120°C), water ash The ratio is 0.45;

[0042] Middle layer spacer formula: clear water, 0.5% polyacrylamide aqueous solution should be used 500m below the surface cement plug contact surface, and the 0.5% polyacrylamide aqueous solution should be prepared 4 hours in advance;

[0043] Surface cement plug formula: G-grade high sulfate-resistant oil well cement plus 1% dispersant plus 1% fluid loss reducer plus 0.05% retarder, and the water-cement ratio is 0.45.

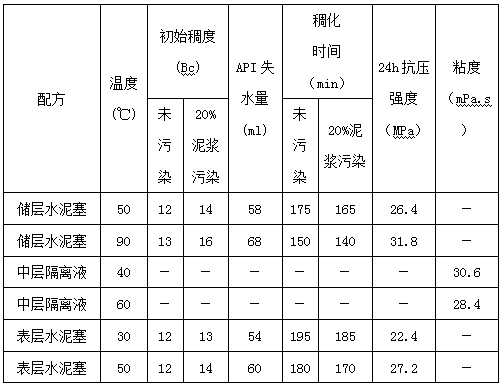

[0044] The related properties of cement slurry and spacer fluid are carried out according to the requirements of GB / T19139-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com