Elastic rigid centralizer

A technology of centralizer and centralizing strip, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., which can solve the problems of limited centering effect of centering, centering of casing string, difficulty in drilling operation or well completion operation, etc., and achieve good centering effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

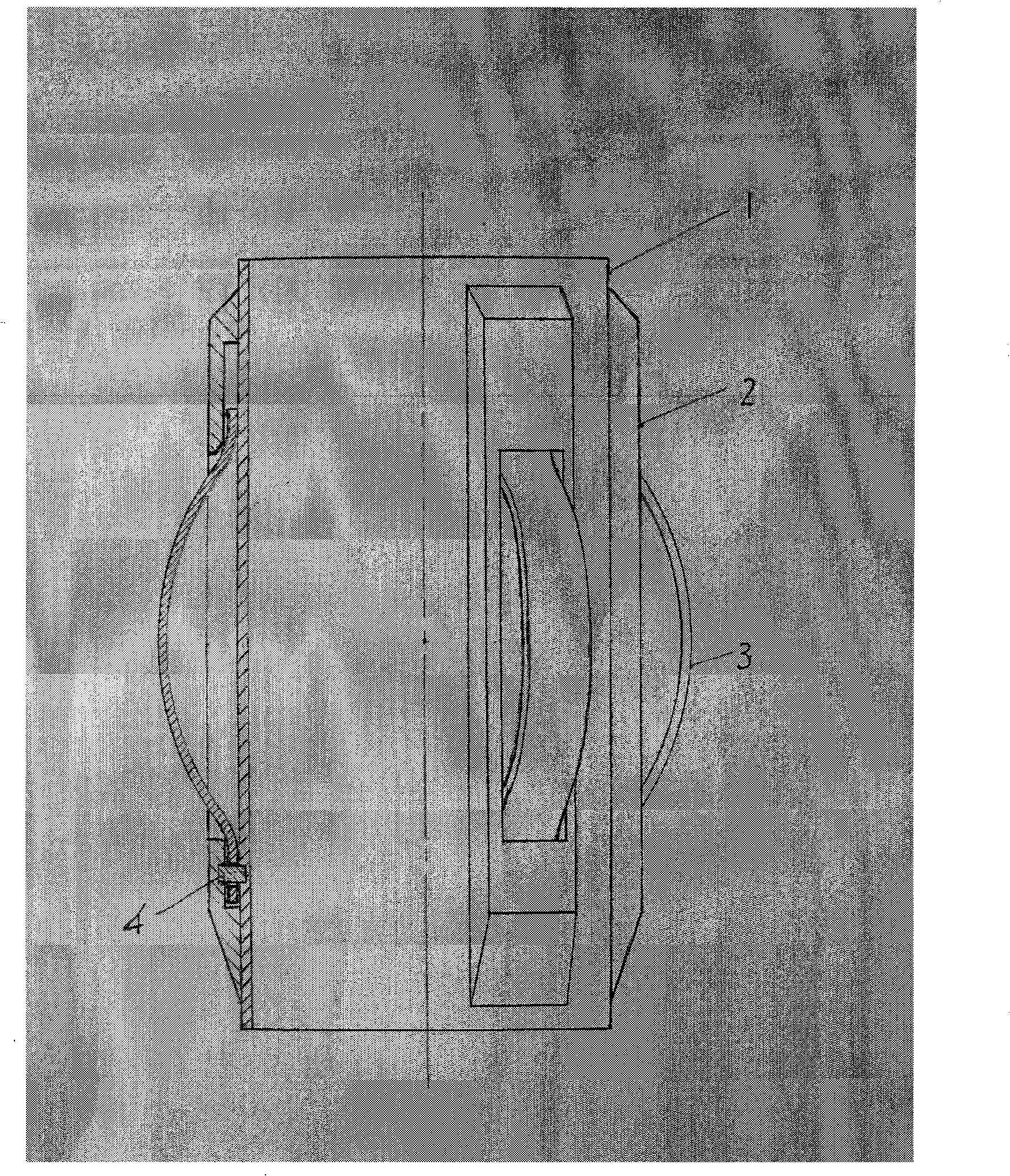

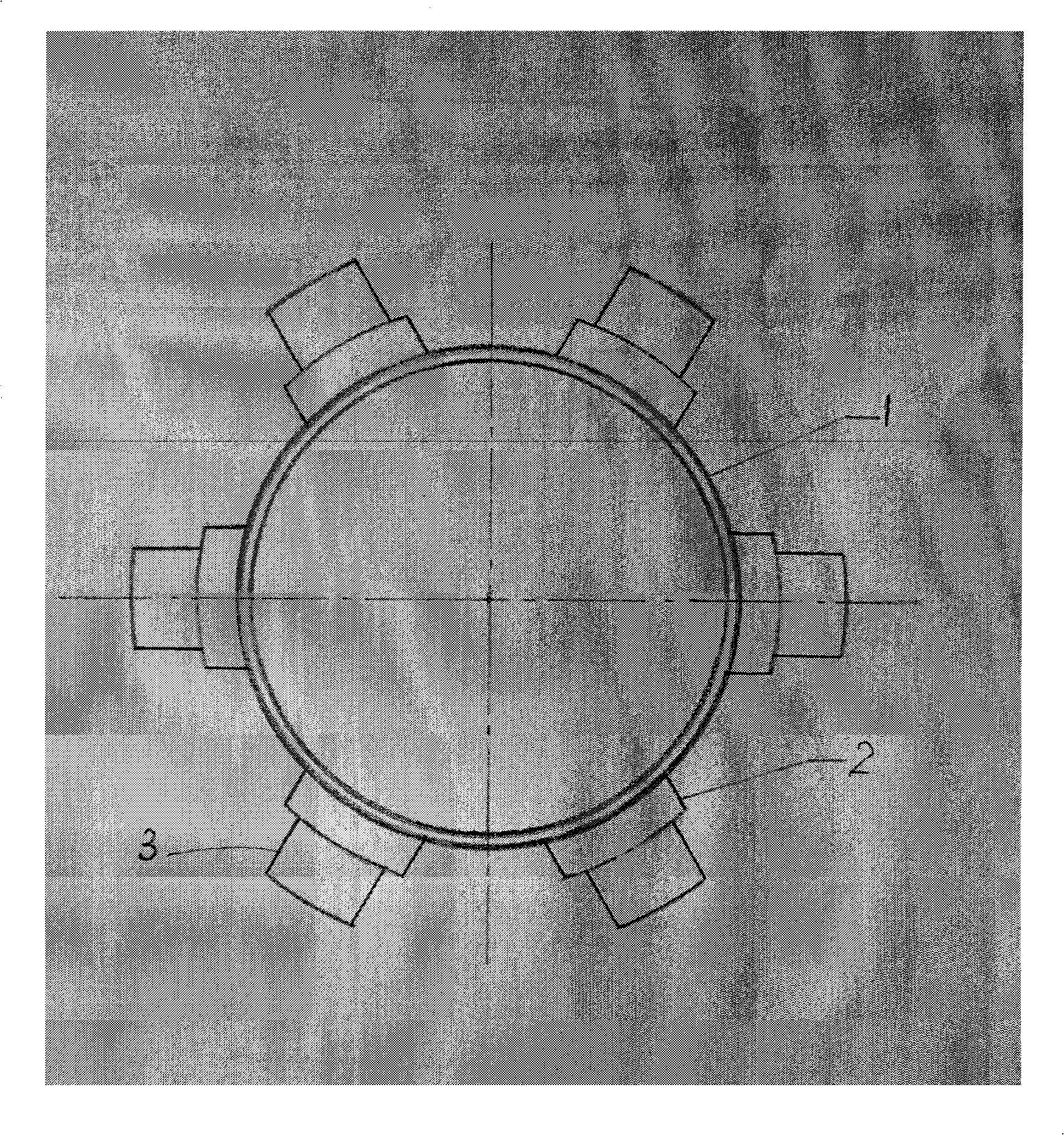

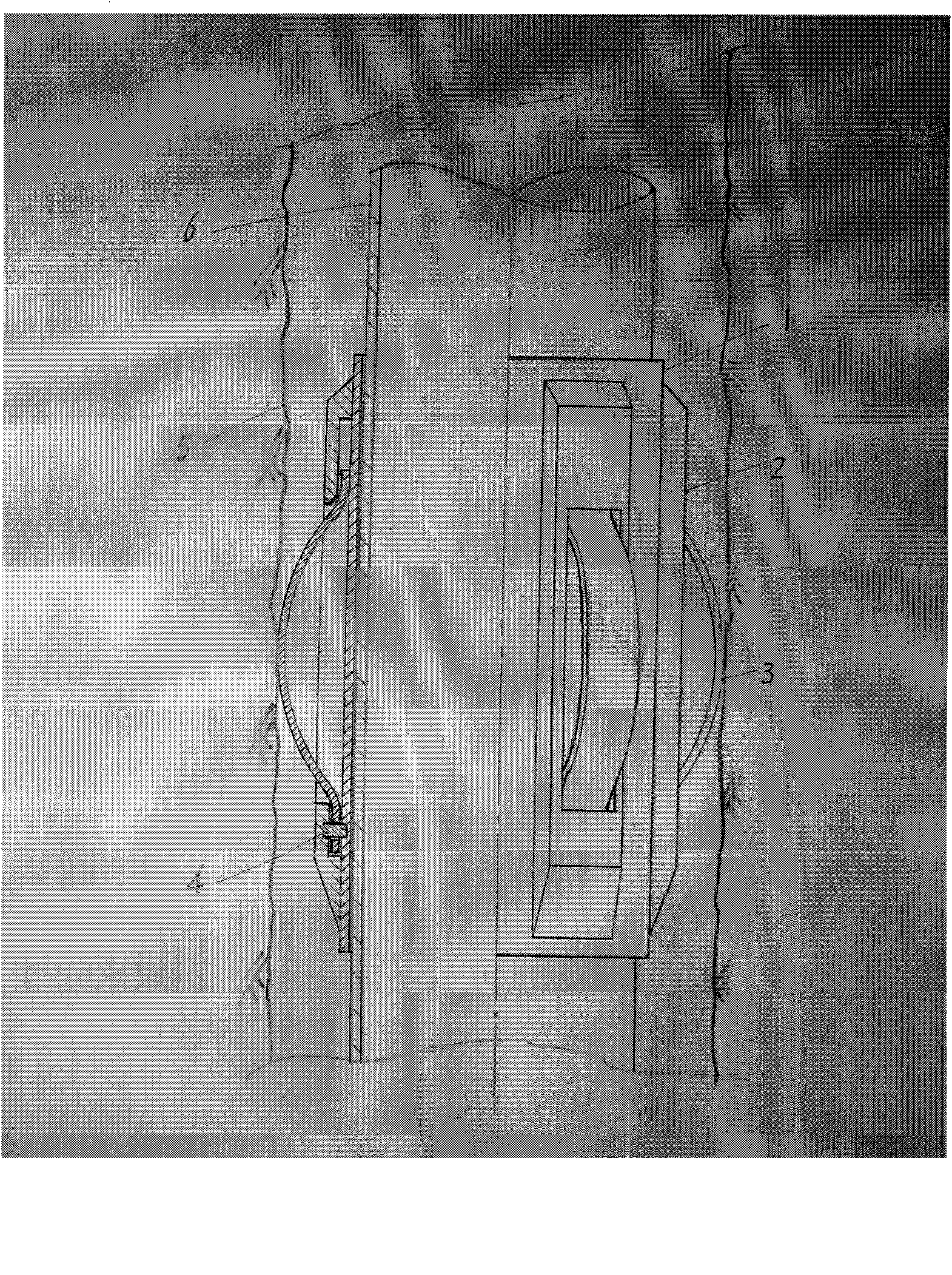

[0012] 1. As attached figure 1 As shown, the present invention mainly consists of a body (1) and several rigid centralizing strips (2) uniformly distributed in the circumferential direction of the body (1). In the groove, one end that enters the well downward is relatively fixed with a lock pin (4), and the other end is a free end that can slide within a limited range in the axial direction in the groove.

[0013] 2. As a further improved embodiment of the invention. Several rigid centralizing strips (2) evenly distributed in the circumferential direction of the body (1) of the present invention are provided with an "inverted T-shaped" chute, and leaf spring centralizing pieces (3) with micro-steps at the end are installed in the groove. It is a free end that can slide within a limited range in the axial direction in the groove.

[0014] 3. As a further im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com