Well cementing cement slurry stabilizer, preparation method and applications thereof

A cement slurry and stabilizer technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems affecting the performance of wenlun glue stabilizer, affecting the preparation process of cement slurry, and the consistency of cement slurry, etc., to achieve effective It is conducive to normal pumping, prevents free liquid and settlement, and improves the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] (b) Preparation of main chain AA / AMPS copolymer: Dissolve 471g of AA and 729g of AMPS in 4800g of deionized water, transfer to a 10L three-port reaction vessel, stir at a speed of 200r / min and turn on the heating device, wait until the temperature When the temperature rises to 60°C, add 7.2g of potassium persulfate and react for 5 hours to obtain a colorless and transparent solution; after the reaction is completed, add an appropriate amount of sodium hydroxide to adjust the pH of the reaction solution to be neutral, and use a vacuum freeze dryer to freeze-dry to make a powder The AA / AMPS copolymer of shape is for standby;

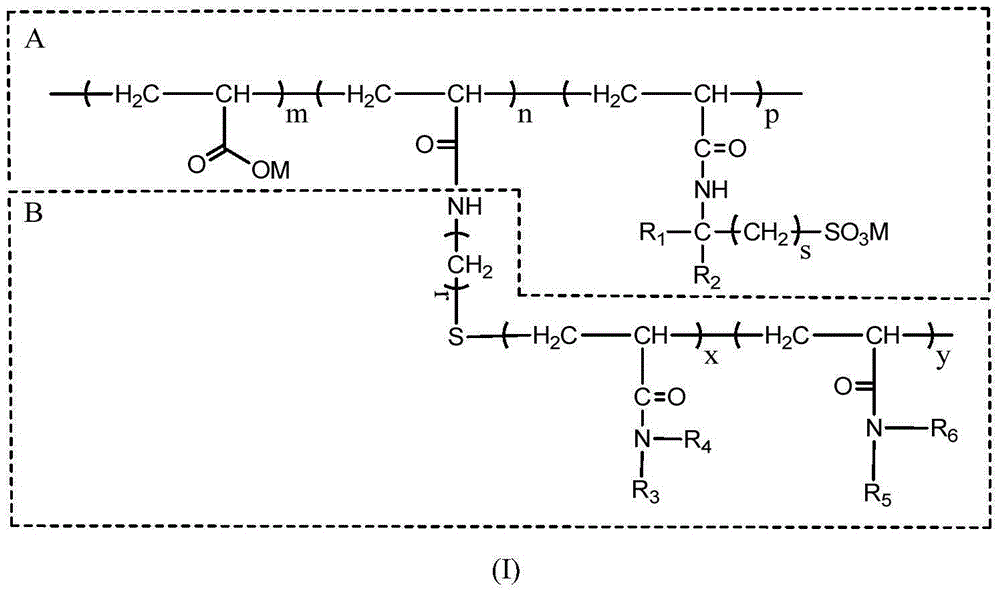

[0051] (c) Preparation of grafted polymer: KH 2 PO4 and Na 2 HPO 4 Prepare a buffer solution with a pH of 7.4, add 962g of side chain NIPA / DMAA copolymer and 438g of main chain AA / AMPS copolymer to 5600g of the above buffer solution, stir until completely dissolved; then add 5.23g of 1-ethyl -(3-Dimethylaminopropyl)carbodiimide hydrochloride and ...

Embodiment 1

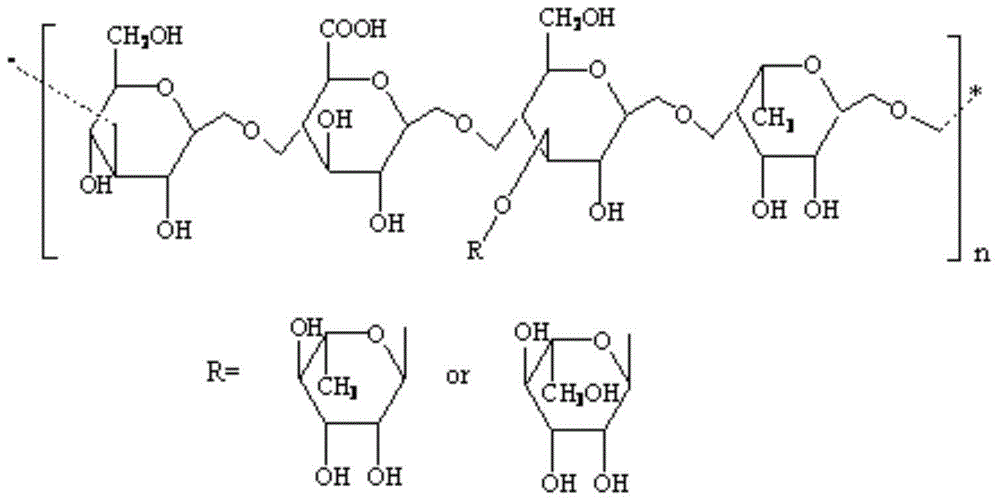

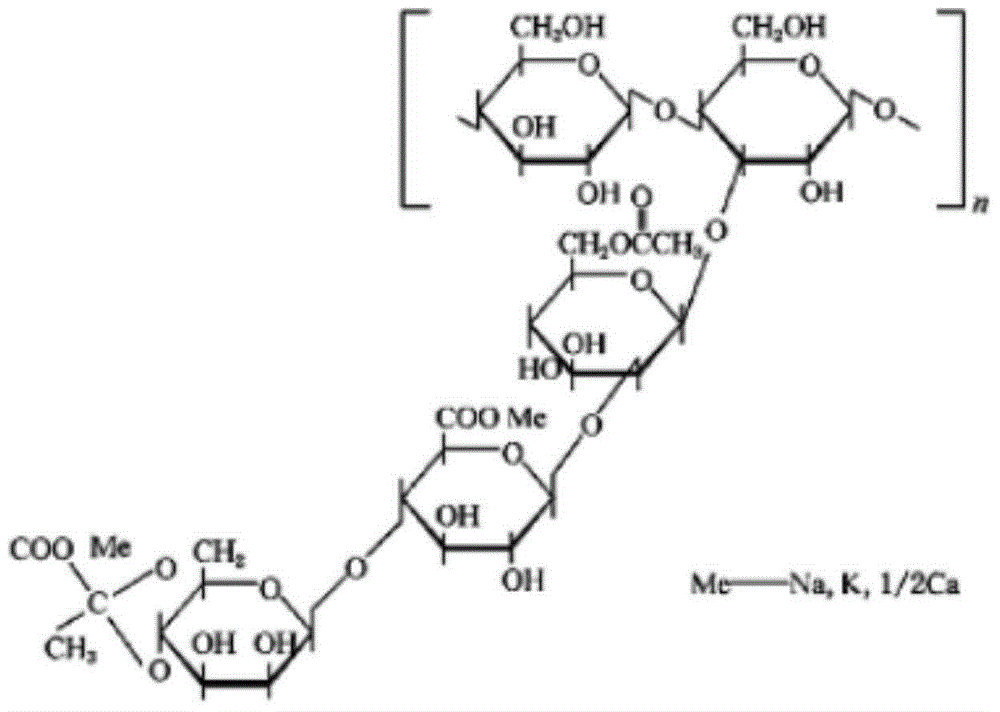

[0053] Weigh 14.8Kg of quartz sand and put it in the powder mixer, start the stirring device and stir at a speed of 30r / min, then add 1.0Kg Wenlun gum, 1.6Kg xanthan gum, 1.0KgPVA-1788, 1.6 Kg of grafted high molecular polymer, after stirring continuously for 90 minutes according to the above speed, the cement slurry stabilizer of this embodiment can be obtained, which is recorded as WDJ-1.

Embodiment 2

[0055] Weigh 15.4Kg of quartz sand and place it in the powder mixer, start the stirring device and stir at a speed of 40r / min, then add 1.6Kg Wenlun gum, 1.0Kg xanthan gum, 1.4KgPVA-1788, 0.6 Kg of grafted high molecular polymer, after stirring continuously for 70 minutes according to the above speed, the cement slurry stabilizer of this embodiment can be obtained, which is recorded as WDJ-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com