Slide ring seal

A technology of slip ring seals and seals, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., to achieve the effect of increasing torque retention, increasing service life, and preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

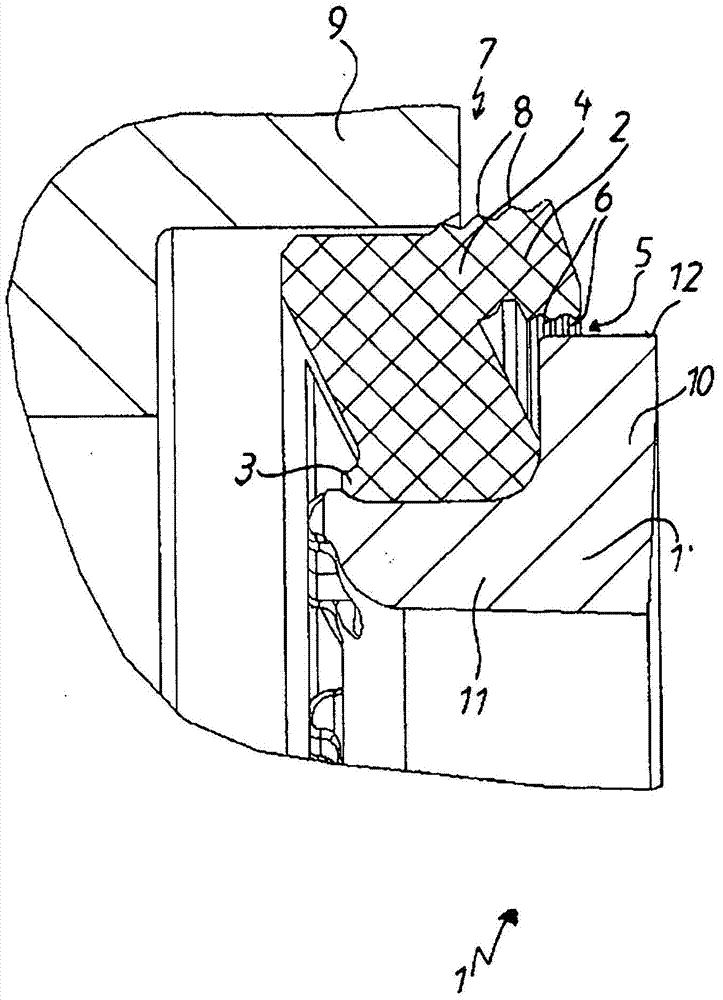

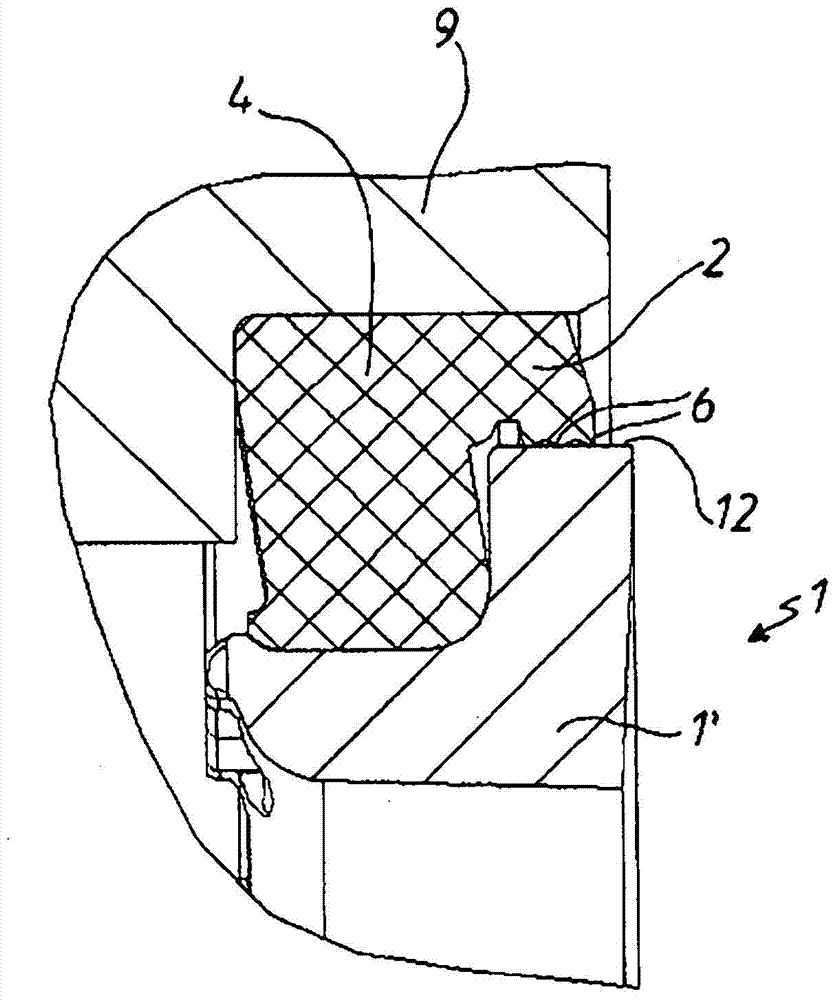

[0020] figure 1 Shown is a sectional view of a sliding ring seal 1 configured as a running gear seal in a pre-assembly position, which contains a sealing body 2 made of an elastomer material. The sealing body 2 has a surrounding base body with an approximately trapezoidal cross-section, on which, viewed in the circumferential direction, a bead 3 extending in the radial and axial direction is integrally formed. These flanges 3 form a later anti-twist protection for the slip ring seal 1 . Also integrally formed from the sealing body 2 is an axial arm 4 that extends in the axial direction and is designed as a collar. The flange 4 has, on its inner peripheral surface 5, formed parts 6 forming an anti-fouling lip, by means of which the flange is supported on the slip ring 1'. According to requirements, the profile 6 can be configured as a labyrinth seal or also as a corrugated profile with different geometrical contours. The axial arm 4 thus forms a secondary seal. On the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com