Gate valve

A gate valve and valve sleeve technology, applied in the direction of sliding valve, valve detail, valve device, etc., can solve the problem of not being able to close completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

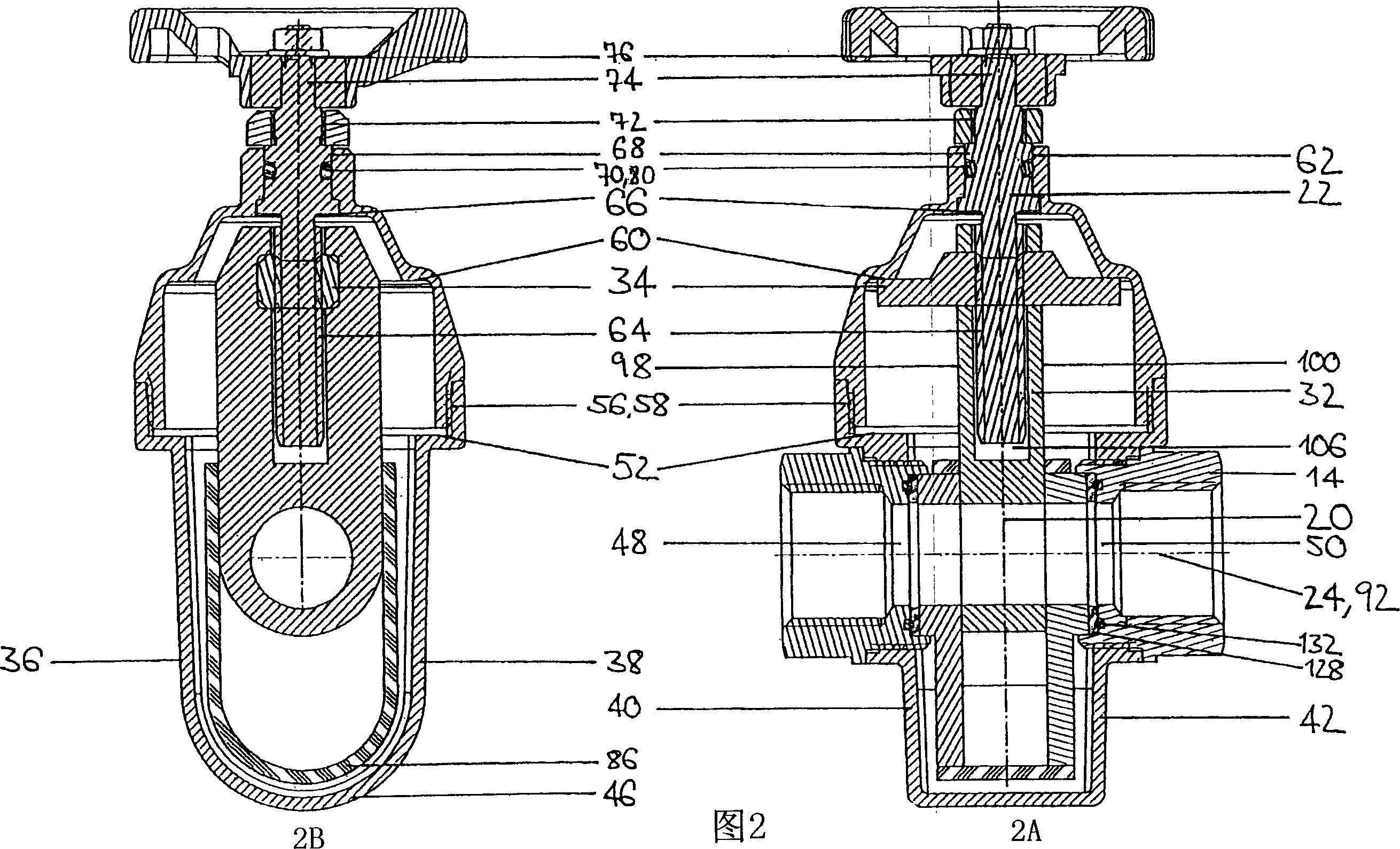

[0025] In the following description of embodiments by way of example, terms such as "left", "right", "top", "bottom", "inner", "outer", "vertical" or "horizontal" Corresponds to the description of the valve in the accompanying drawings. These terms have been chosen only to facilitate the existing description and in no way be considered as limiting the scope of protection of the described valve, which can be installed in any spatial position.

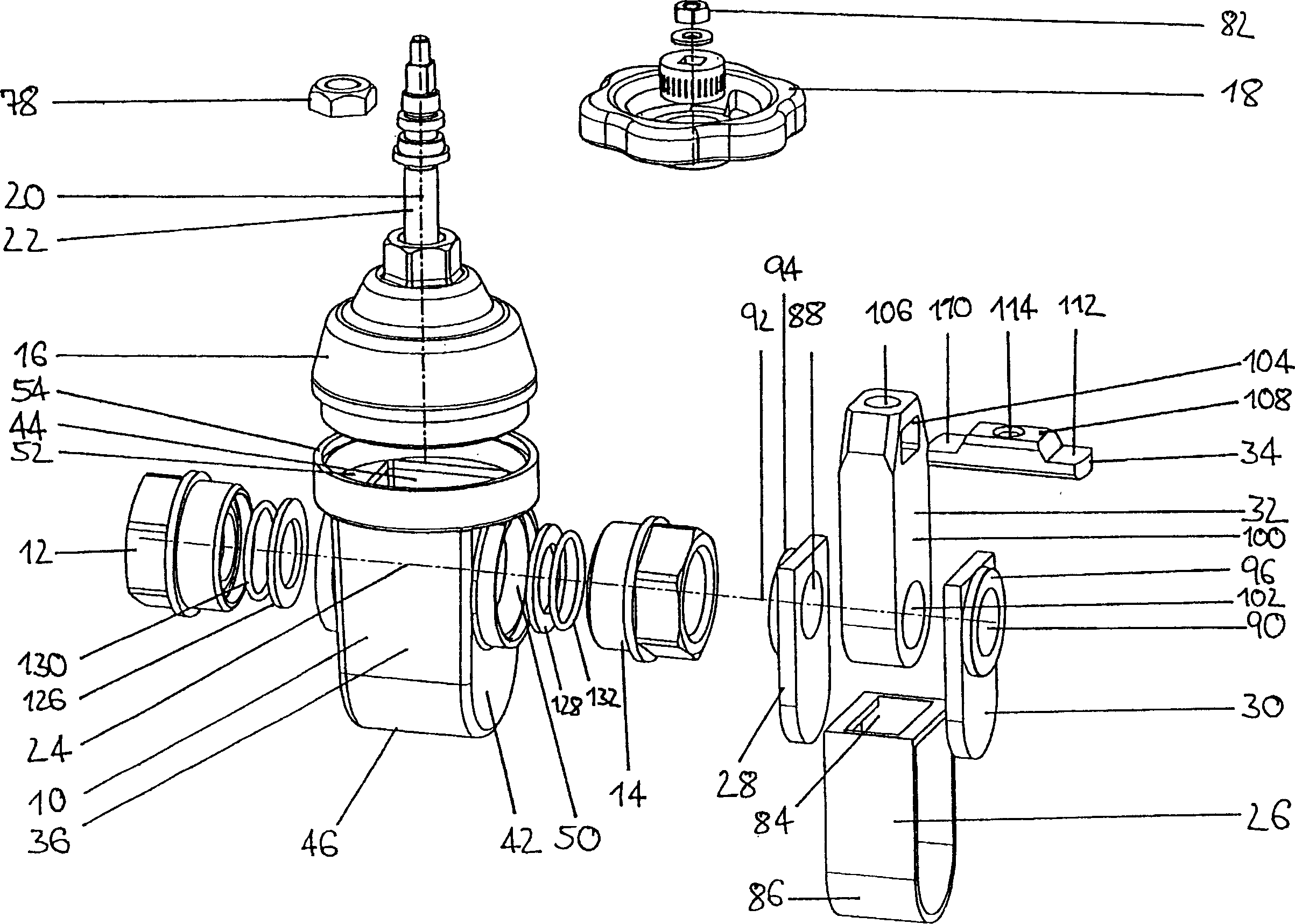

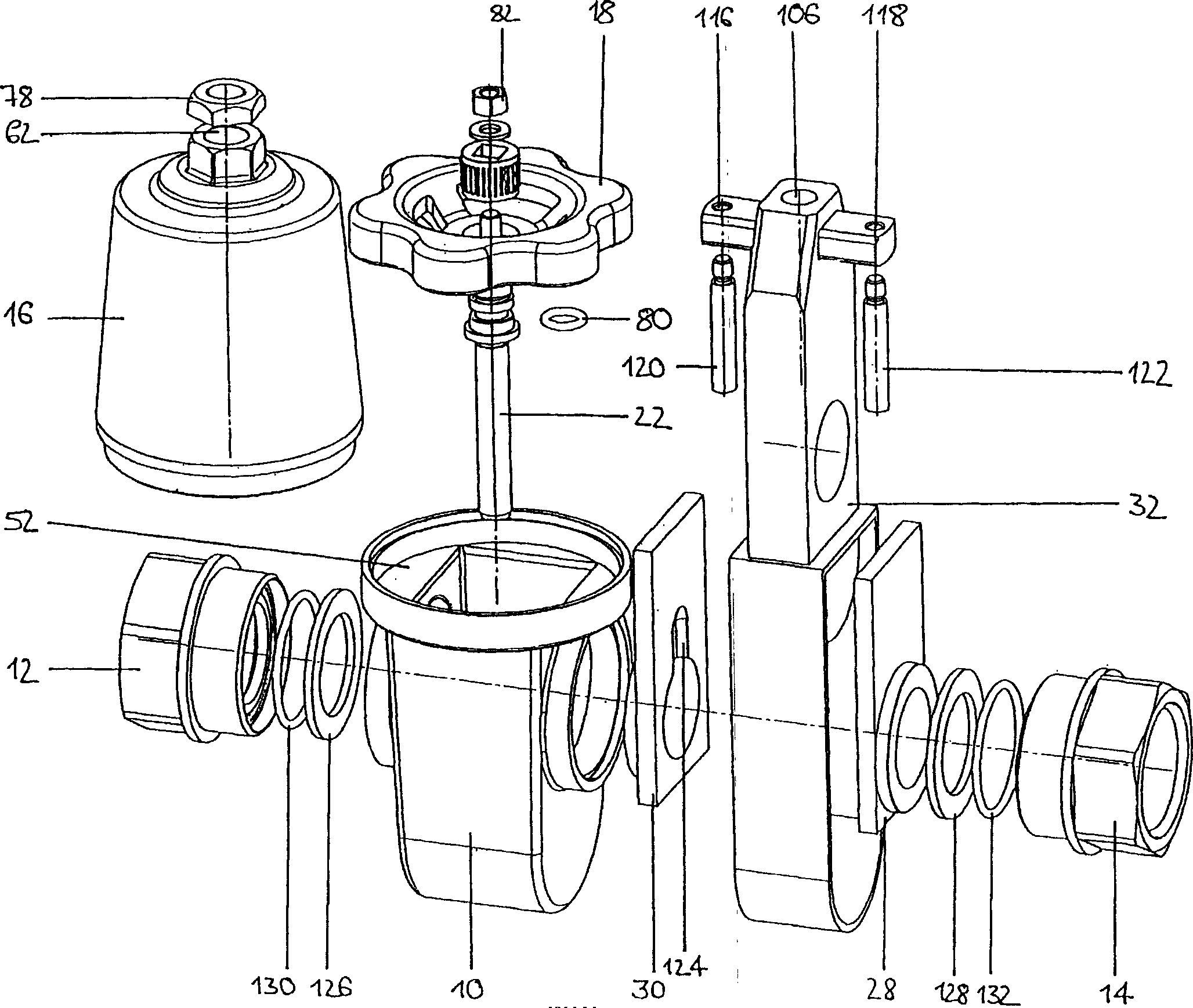

[0026] The components of the valve are first described with reference to an exemplary embodiment. Components having the same function are numbered in the same way in the figures.

[0027] The valve, especially for liquids, has a valve housing 10, connecting members 12 and 14 for input and output, a cover 16 on the valve housing 10, and a valve shaft 22 which can pass through an actuating member— For example a hand wheel 18 - which rotates about a vertical axis 20 . In the illustrated embodiment, the connecting members 12 , 14 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com