Flap arrangement for turbine, turbine, and exhaust gas turbocharger

一种废气涡轮、涡轮机的技术,应用在发动机元件、机器/发动机、升阀等方向,能够解决泄漏、热变形、增加泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An exemplary embodiment of a flap arrangement 10 according to the invention as well as a turbomachine with such a flap arrangement 10 and a corresponding exhaust gas turbocharger are described below with the aid of the figures.

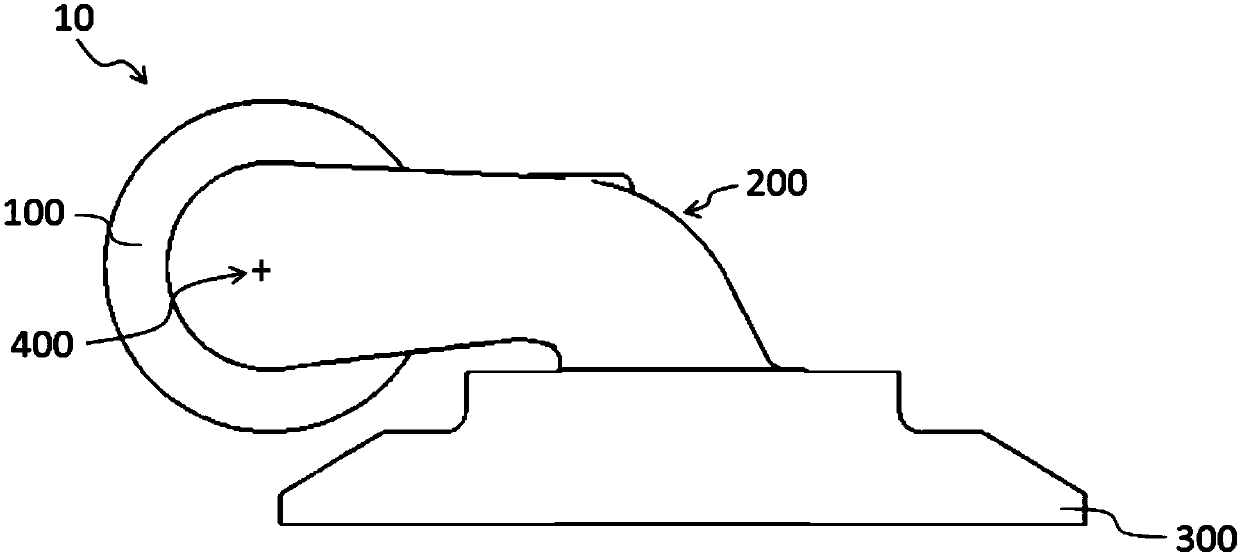

[0023] figure 1 A flap assembly 10 known from the prior art for a turbine of an exhaust gas turbocharger is shown. The flap assembly 10 has a spindle 100 , a lever arm 200 and a flap disc 300 . When used in an exhaust gas turbocharger, the flap assembly 10 is mounted in the turbine housing rotatably about the axis of rotation 400 via the main shaft 100 so that the valve flap assembly 10 can be used to close or release the passage in a targeted manner. Holes, such as through-holes for wastegates.

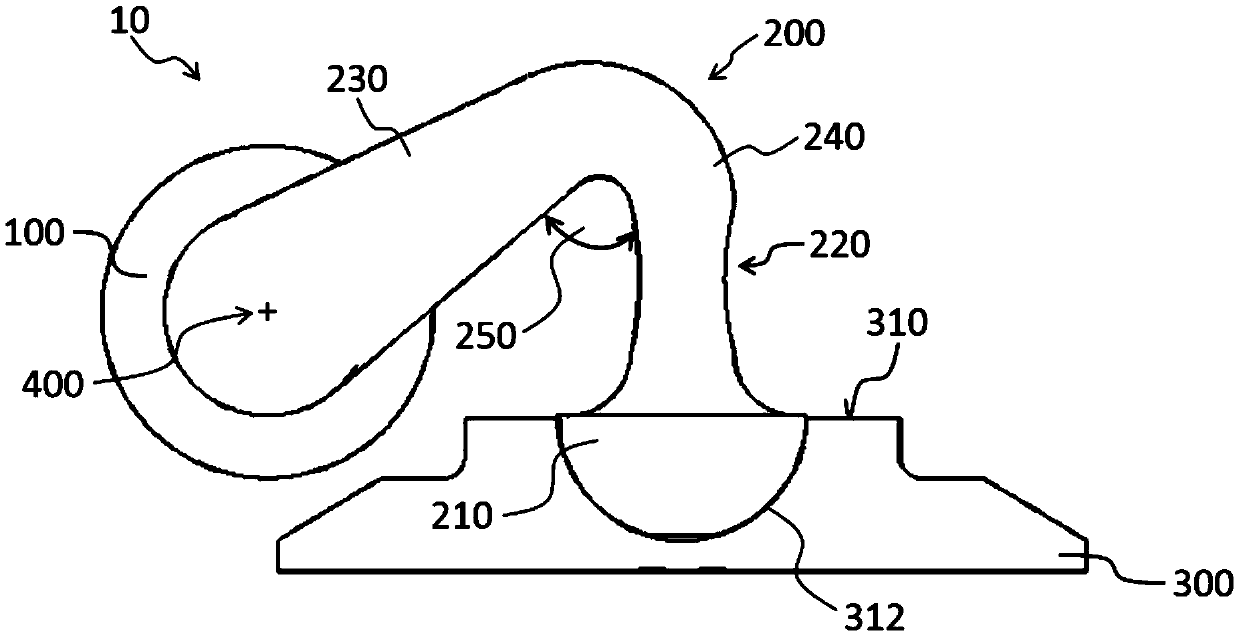

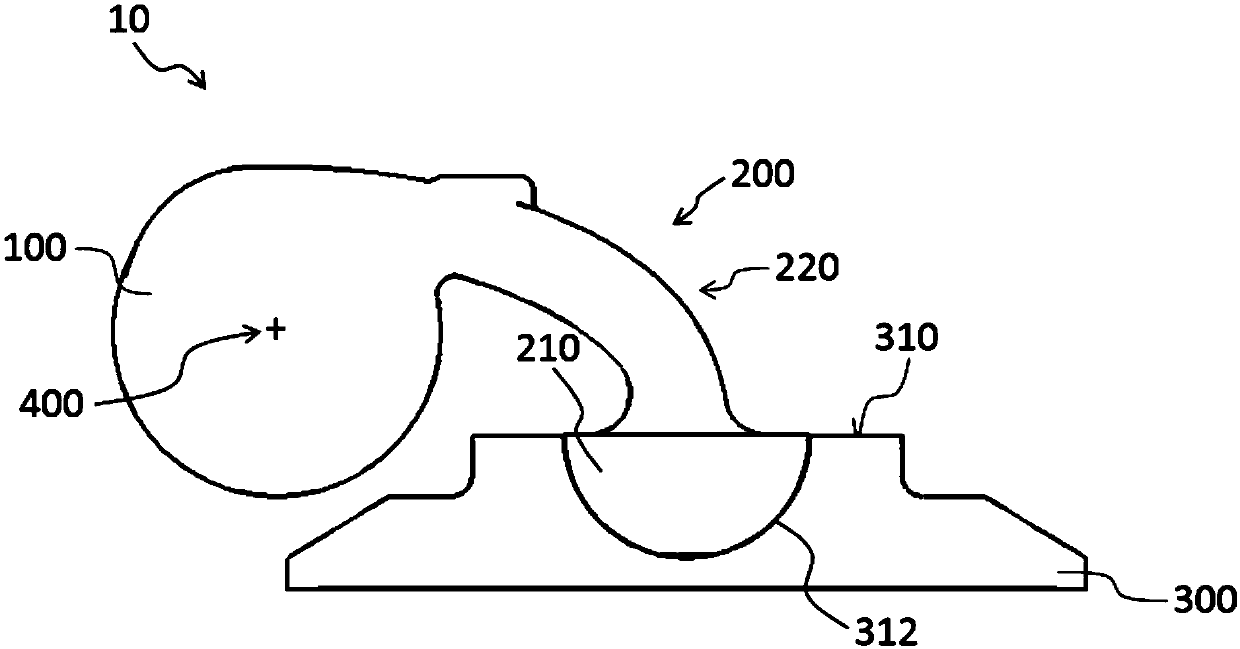

[0024] figure 2 and image 3 An exemplary embodiment according to the invention of a flap assembly 10 for a turbine of an exhaust gas turbocharger, in particular for a wastegate valve of a turbomachine, is shown. The flap assembly according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com