Knife-type water filling valves for flat gates in rivers with heavy sediment

A flat gate and water filling valve technology, applied in sliding valves, valve devices, water conservancy projects, etc., can solve the problems of large closing force, difficulty in ensuring the reliability of valve opening and closing, and reduce the closing force and structure. Simple, improve the effect of the leakage state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

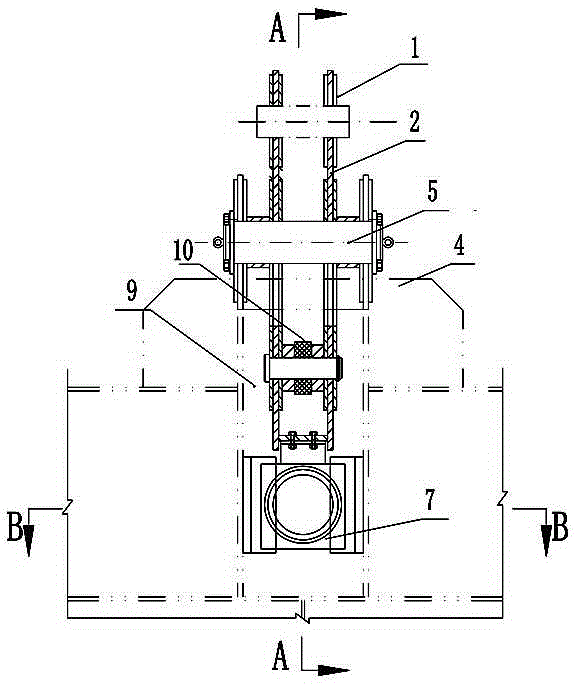

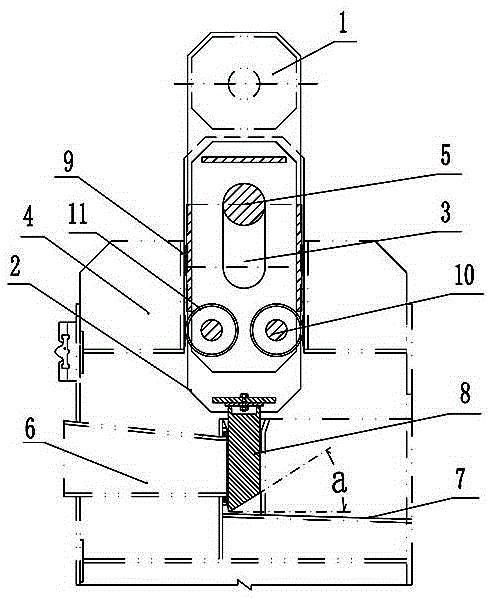

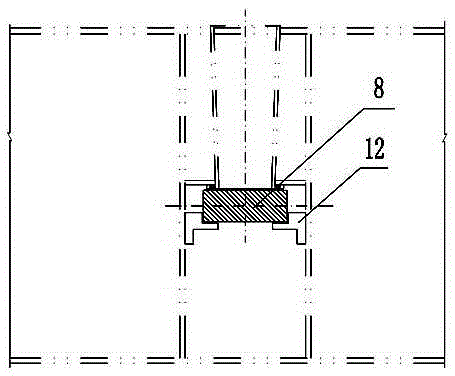

[0010] Such as figure 1 , 2 As shown, the knife-type water filling valve for the planar gate of a river with many sediments according to the present invention includes a boom 2 whose top is hinged to the hoist head 1, and a hole in the middle of the boom 2 along the longitudinal direction. Groove 3, the load-bearing shaft 5 fixedly connected with the plane gate 4 set through the hole groove 3, the valve plate 8 arranged in the valve chamber between the water inlet 6 of the plane gate 4 and the discharge groove 7, the upper end of the valve plate 8 part is connected with the lower end of the boom 2; the lower end surface of the valve plate 8 is a cutting edge structure inclined upward toward the downstream side, and the inclination angle a is selected between 30°-50°; The longitudinal section is a U-shaped structure, and the guide wheels 10 and 11 that are rollingly matched with the corresponding gate groove 9 are arranged in the suspender 2 of the U-shaped structure below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com