Door assembly and clothes treating apparatus

A technology of door components and components, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient assembly of door glass and poor buffering effect of door glass, etc., achieve reliable assembly, reduce the risk of leakage, and reduce the peak value The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

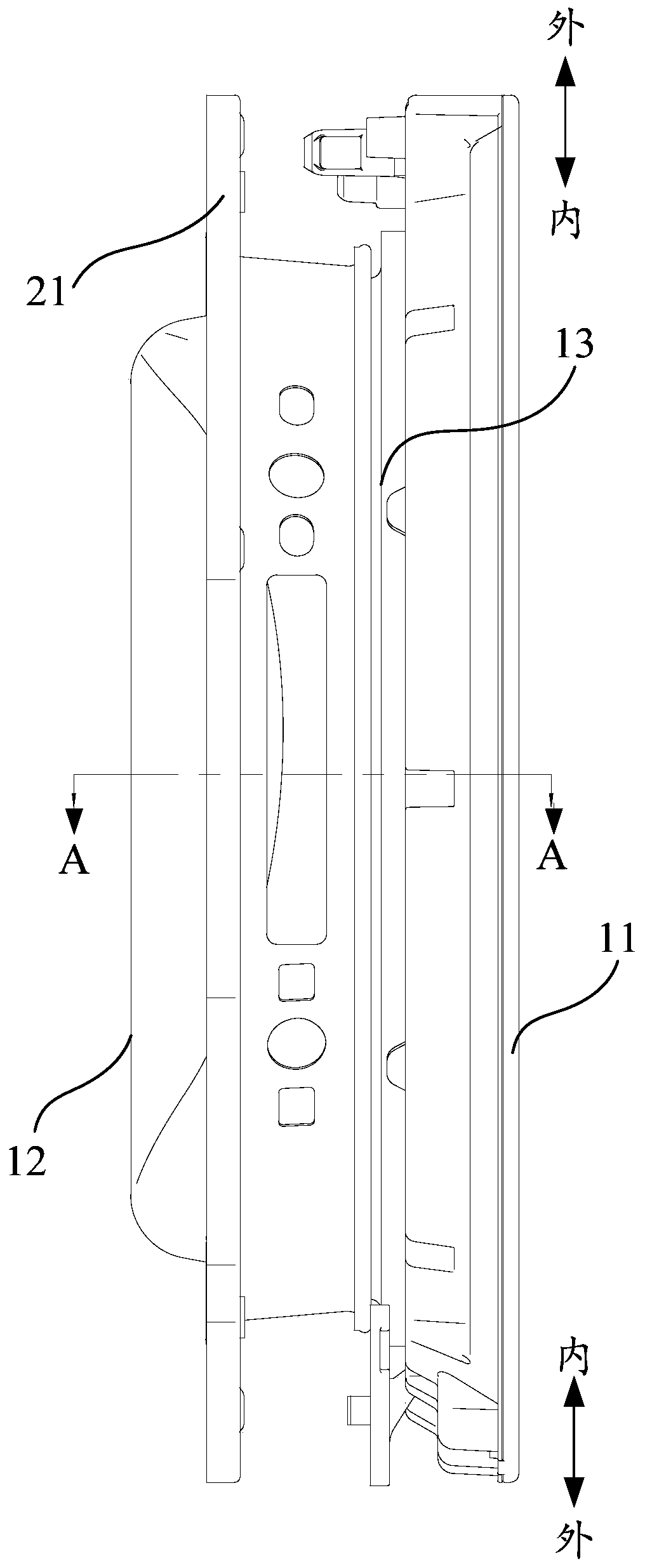

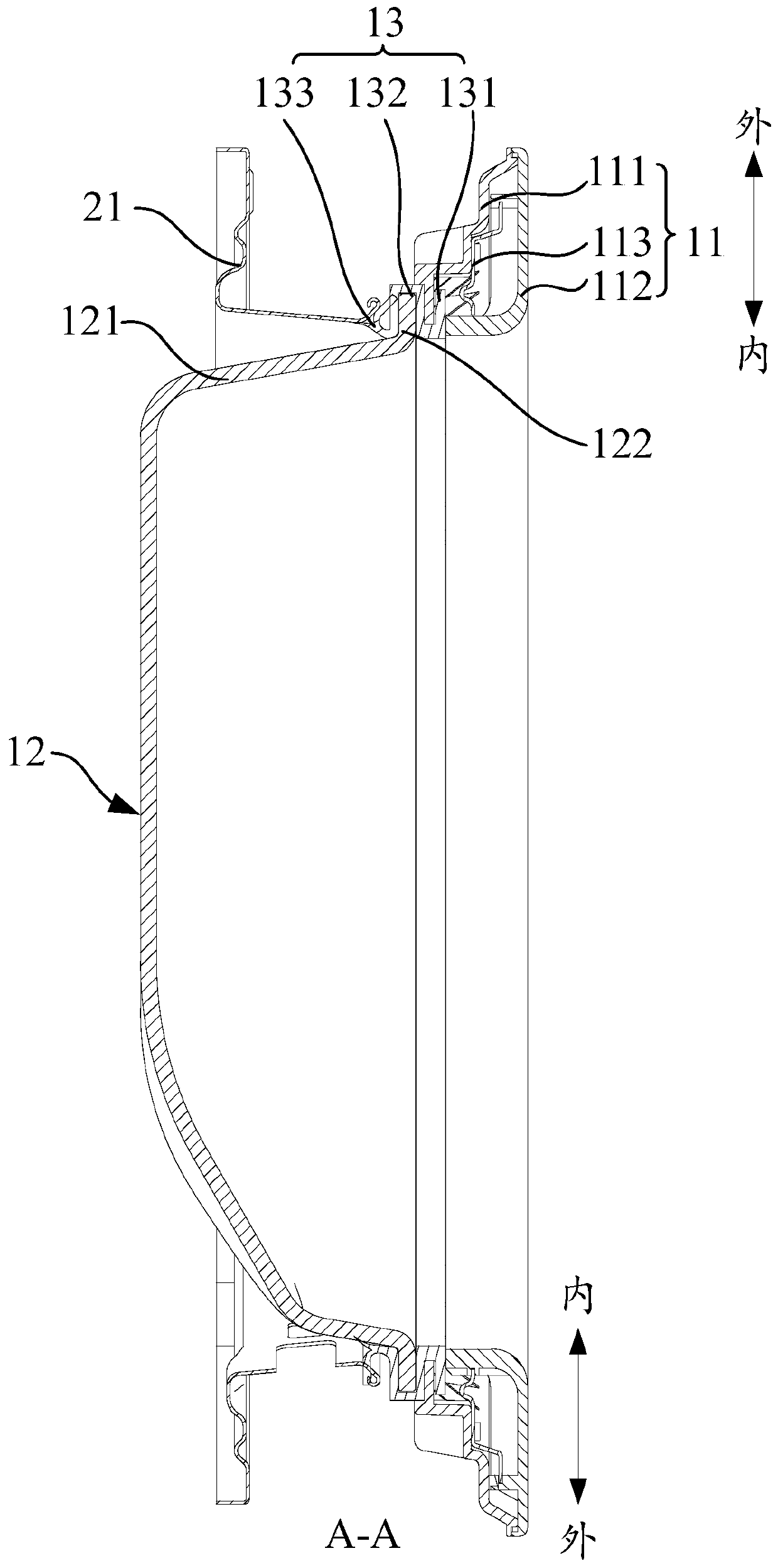

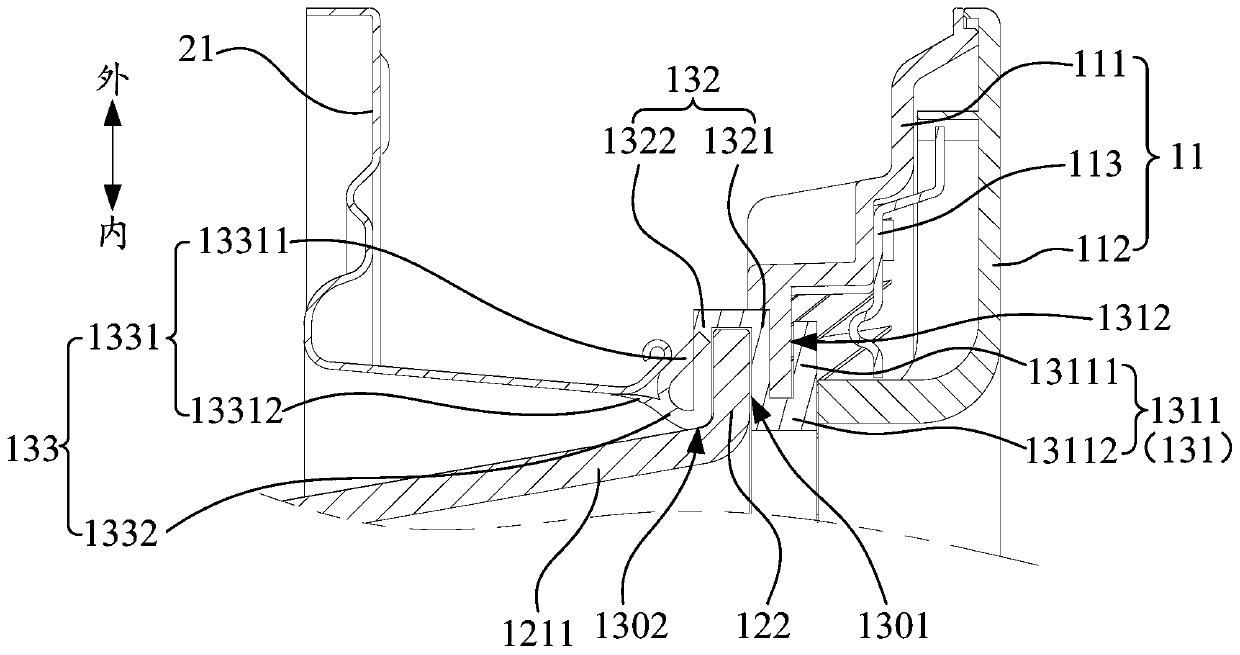

[0048] In addition to the features of the above embodiments, it is further defined that the door glass 12 includes an adapter portion 121 and a flange 122 protruding outward from the side wall of the adapter portion 121, and the flange 122 can be around the adapter portion 121 The annular flange structure arranged in a circle can also be a lug arranged at a certain radial position of the fitting part 121 , or a lug arranged discontinuously along the circumferential direction of the fitting part 121 . The door sealing ring 13 is formed with a fitting installation hole 1302 and a groove 1301 formed by the depression of the inner wall of the fitting installation hole 1302. The fitting part 121 is inserted into the fitting installation hole 1302, and the flange 122 extends into the groove 1301. Inside. In this way, the alignment and positioning of the door glass 12 is realized by fitting the mounting hole 1302, which is beneficial to reduce the difficulty of assembly and improve t...

Embodiment 2

[0054] Such as figure 2 As shown, in addition to the features of any of the above-mentioned embodiments, it is further defined that the door sealing ring 13 includes: a door joint part 131, a groove part 132 and a sealing part 133, the door joint part 131 is connected with the door ring assembly 11, and the concave The groove 1301 is formed in the groove part 132, the sealing part 133 is located on one side of the door ring assembly 11, and the sealing part 133 has a sealing fitting part 1331 suitable for sealingly fitting with the front door ring 21 of the laundry treatment device, wherein the groove part 132 extends from the door ring assembly 11 to the sealing portion 133 and connects the sealing portion 133 and the door joint portion 131 .

[0055] For example, a drum washing machine at least includes an outer tub for holding water and an inner tub for accommodating laundry, the outer tub and the inner tub together form the washing tub of the drum washing machine, and the...

Embodiment 3

[0057]In addition to the features of any of the above embodiments, it is further defined that: the outer wall surface of the groove portion 132 is in contact with the door ring assembly 11 or has a distance from the door ring assembly 11 . In this way, the door ring assembly 11 and the door glass 12 are distributed at intervals through the groove portion 132, reducing the transmission of vibration between the door glass 12 and the door ring assembly 11, improving the stability of the door ring assembly 11, and further improving the stability of the door assembly. Reliability, thereby improving the reliability of the door assembly's seal to the wash tub and reducing the risk of leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com