Vehicle lamp bright strip installing structure

A technology for mounting structures and automotive lamps, applied in lampshades, lighting devices, signal devices, etc., can solve the problems of 3M glue failure, warping and deformation, etc., and achieve the effects of stable and reliable bright strip fixing, easy assembly, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

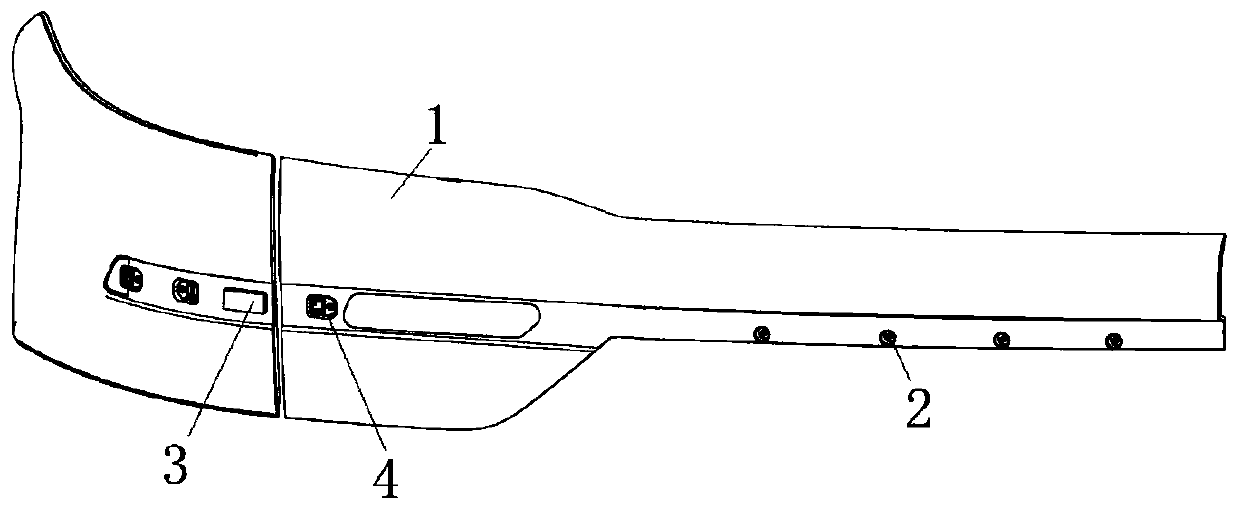

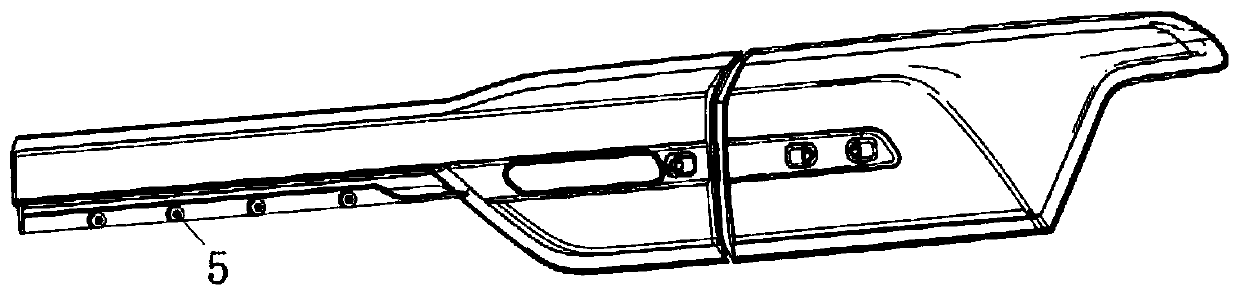

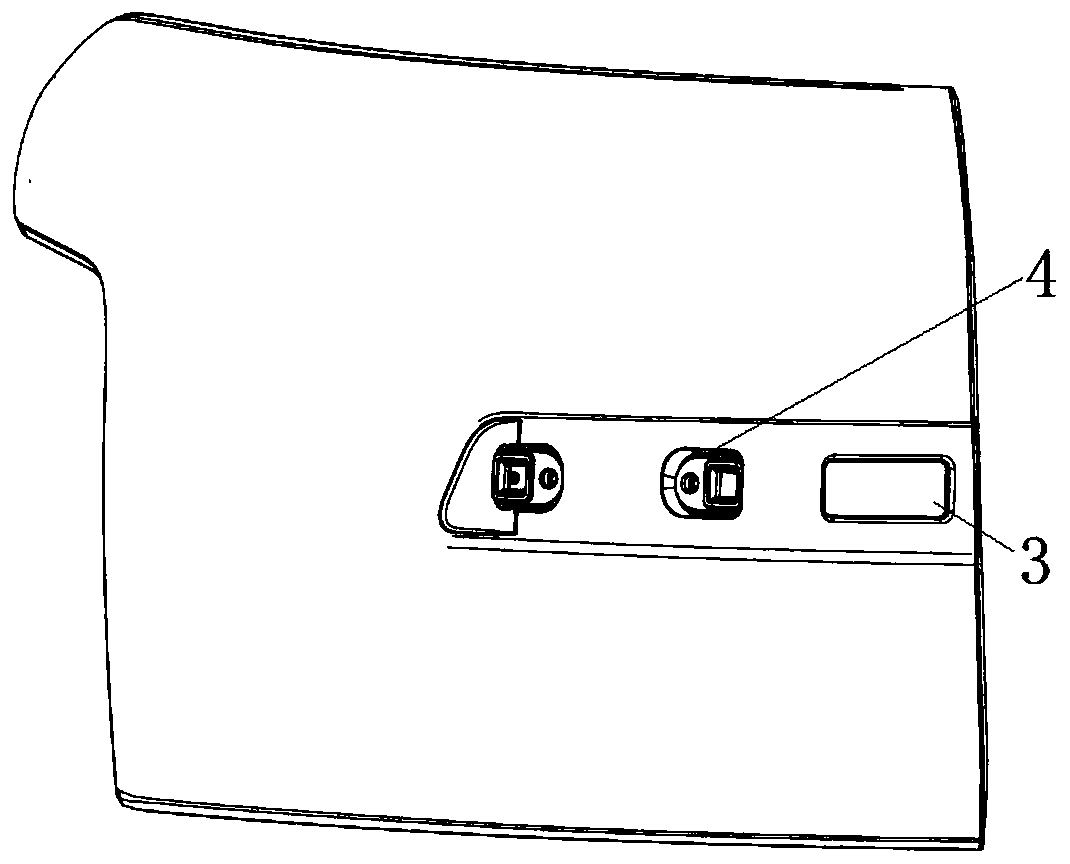

[0024] Such as Figure 1 to Figure 6 As shown, the installation structure of the bright strip of the automobile lamp includes a lamp mask 1, and an installation groove matching the bright strip 7 is arranged on the lamp mask, and a buckle installation groove 401 is provided on the lamp mask in the installation groove, and the snap The buckle installation groove is a fixing groove 4 for positioning the buckle, the buckle installation groove 401 is fixed with a built-in fixing buckle 6 by a fastener, and the back of the bright strip is provided with a clip that is compatible with the built-in fixing buckle .

[0025] The lamp mask 1 is provided with a positioning groove 2 in the installation groove, the back of the bright strip is provided with a positioning column matching the positioning groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com