Small electronic equipment mounting structure based on novel screw

An electronic equipment and installation structure technology, applied in the field of installation structure of small electronic equipment, can solve the problems of cumbersome installation process, increased production cost, troublesome installation process, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

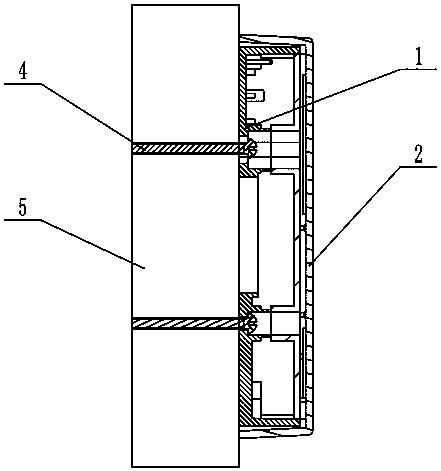

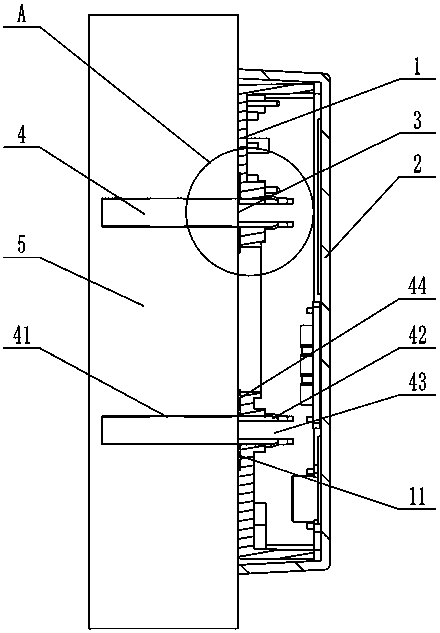

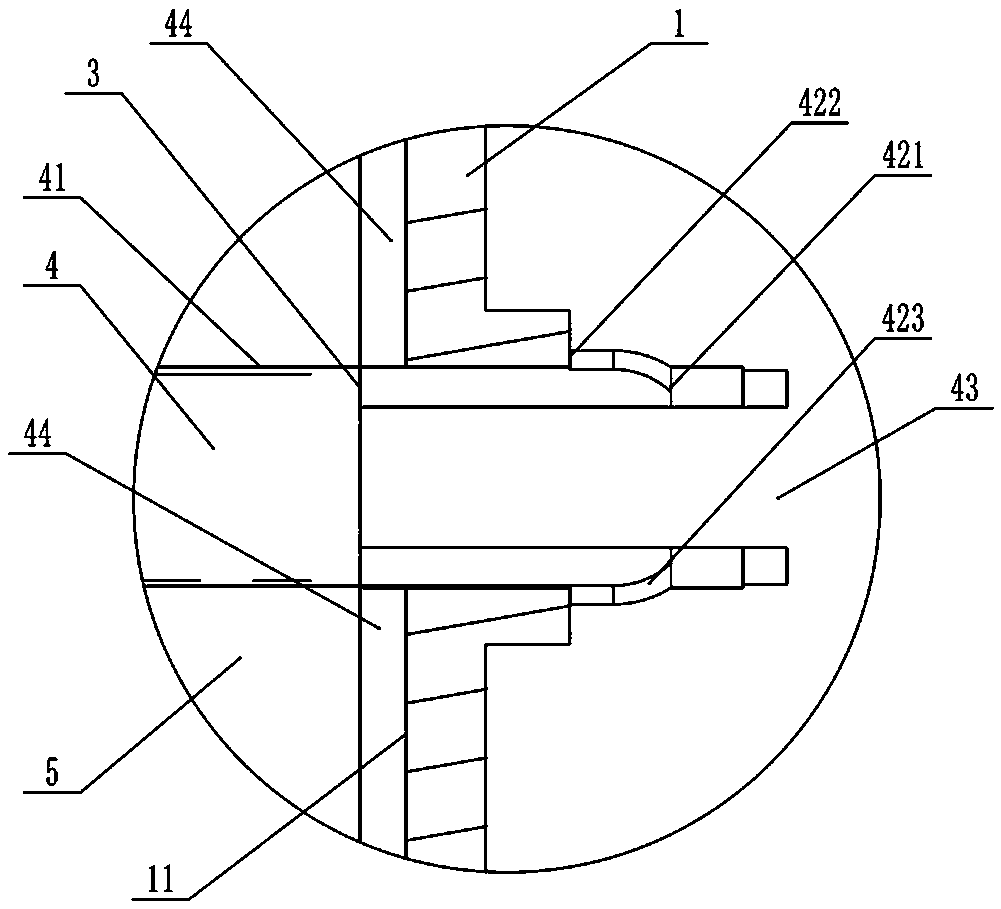

[0021] Such as figure 2 , 3 As shown, the novel screw-based small electronic device installation structure described in this embodiment includes a bottom case 1 for setting electronic devices, and an upper cover 2 that closes the entire case. The bottom of the bottom case 1 is provided with a mounting channel The hole 3 is provided with a buckle screw 4 in the installation through hole 3. The buckle screw 4 includes a fixing section 41 inserted into the fixture 5 and a connecting section matched with the bottom case 1. The connecting section A slit 43 is provided on the axial end, and on the outside of the slit 43, a buckle 42 that gradually increases from the connecting section to the fixed section 41 is provided. The outer diameter of the small end 421 of the buckle is smaller than the installation through hole on the bottom shell 1 3, and the outer diameter of the buckle big end 422 is greater than the inner diameter of the installation through hole 3 on the bottom case 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com