Automobile headlamp decorative adhesive strip mounting structure

A technology for mounting structures and automotive headlights, which is applied to vehicle parts, signal devices, transportation and packaging, etc., can solve the problems of obvious clearance, foreign matter retention, high cost, etc., and achieve the effect of uniform matching clearance, reasonable design and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

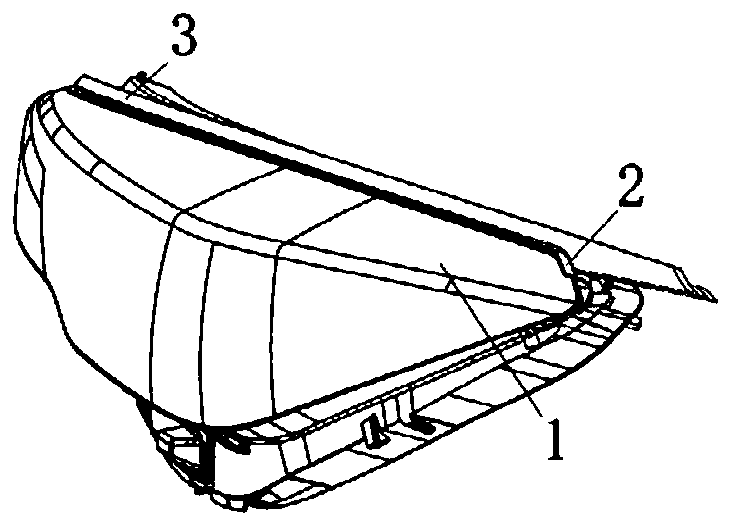

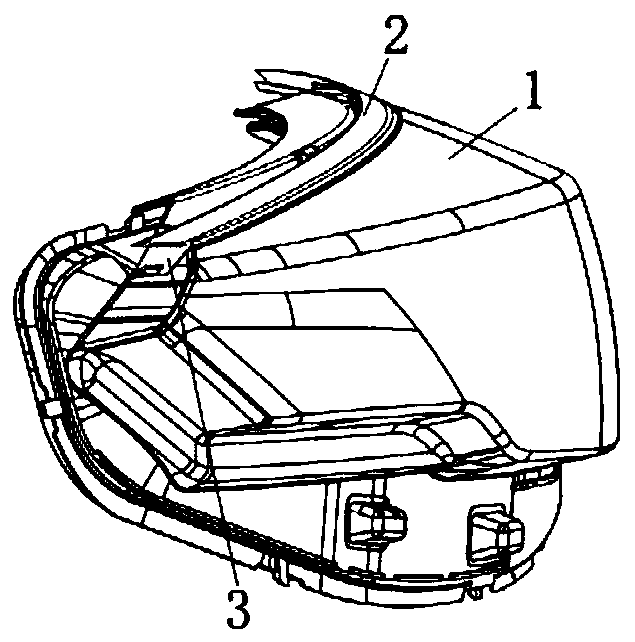

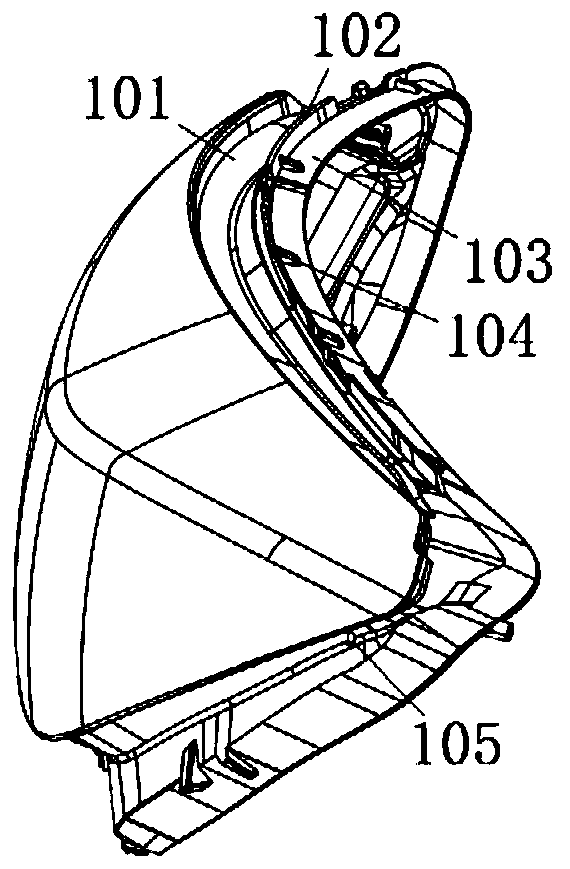

[0030] Such as Figure 1 to Figure 9 As shown, the installation structure of the automotive headlight decorative rubber strip includes a headlight mask 1 and a rubber strip 2. The upper edge of the headlight mask is provided with a positioning groove 101, and the bottom of the rubber strip is provided with a positioning groove corresponding to the positioning groove. Adapted rubber strip tank body 203, the front upper edge of the rubber strip tank body is provided with a matching extension 201 for matching with the front edge of the engine cover of the car, and the matching extension part is located above the groove in the rubber strip tank body. The outer edge of the front portion of the rubber strip groove body cooperates with the front edge of the positioning groove of the headlight mask.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com