Adaptive Flexible Seal

A flexible sealing and self-adaptive technology, applied in the direction of engine sealing, furnace type, furnace, etc., can solve the problems of deformation of connecting transition parts and loss of sealing, and achieve the effect of improving adaptability, simple and convenient installation, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

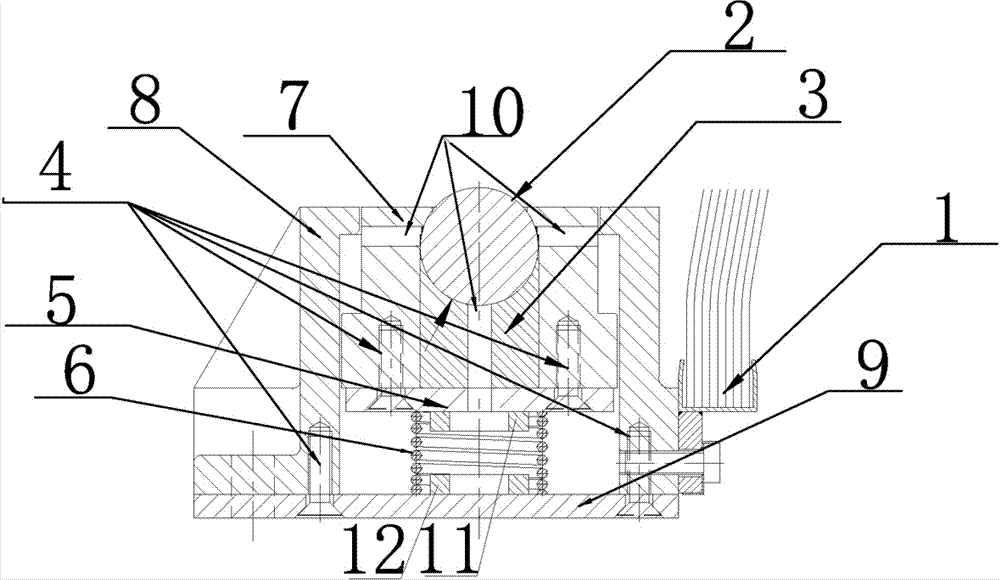

[0015] From figure 1 It can be seen that the present invention includes a long cylindrical roller 2, and the roller 2 is horizontally placed in the semicircular groove provided on the top of the elongated top block 3, and the width of the top block can be the same as the diameter of the roller , the bottom of the top block 3 is provided with a top block base 5 wider than the top block, and an inner sleeve 7 is provided on the left and right sides of the top block 3 and the roller 2, and the roller 2 and the top block 3 are embedded in the inner sleeve 7, Fix the inner cover 7, the top block 3 and the top block base 5 together with the screw 4 from the bottom of the top block base 5; open a long strip hole in the longitudinal direction of the bottom of the top block 3 and the top two sides of the inner cover 7, in this Graphite 10 is embedded in the three holes, so that the roller 2 is in direct contact with the graphite 10 in the three holes, and the graphite 10 plays a lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com