Shaft device for a transmission

A technology for shaft devices and transmissions, which is applied to transmission parts, shafts, couplings, etc., can solve the problems of expensive and high expenditure, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

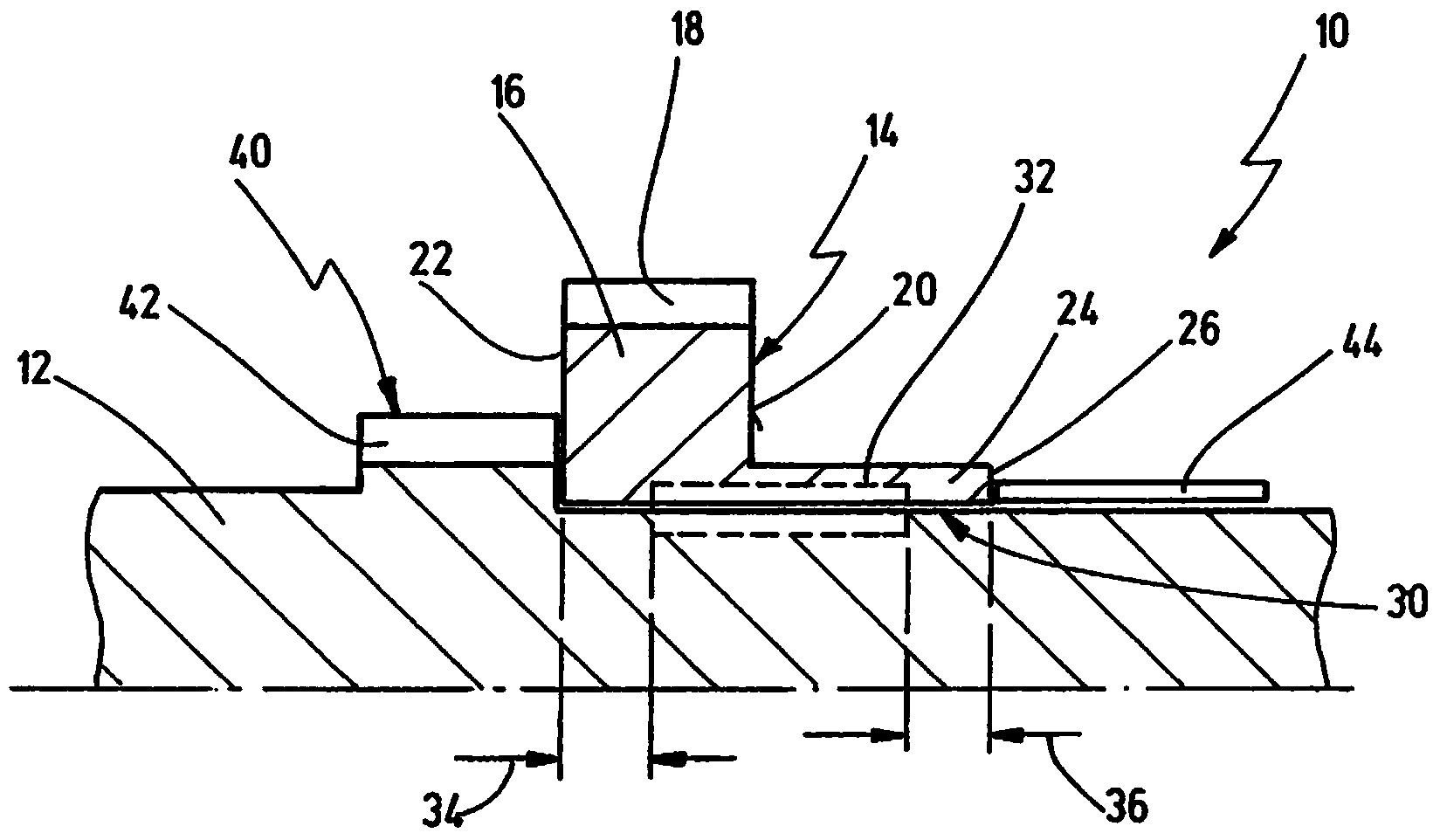

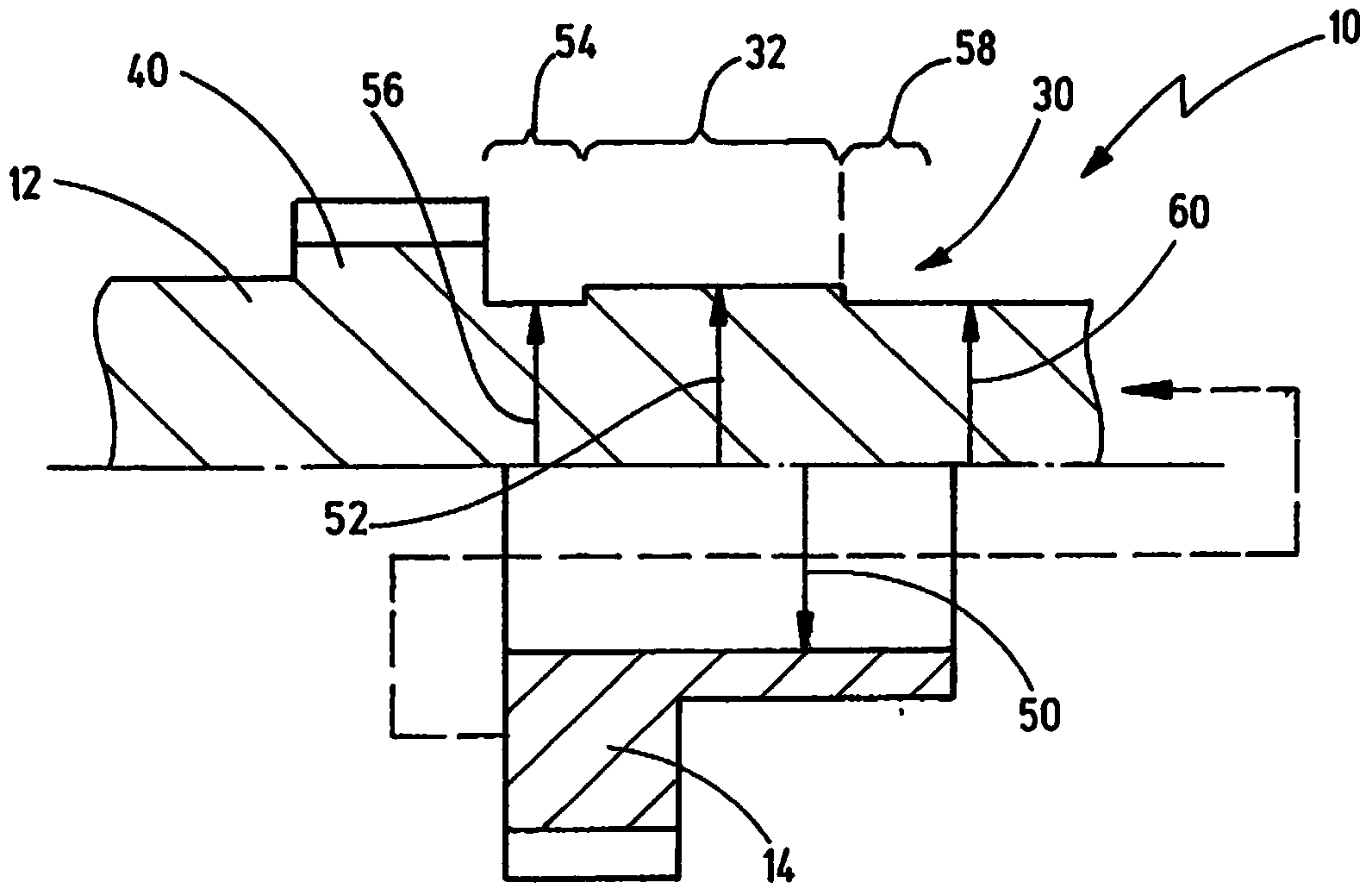

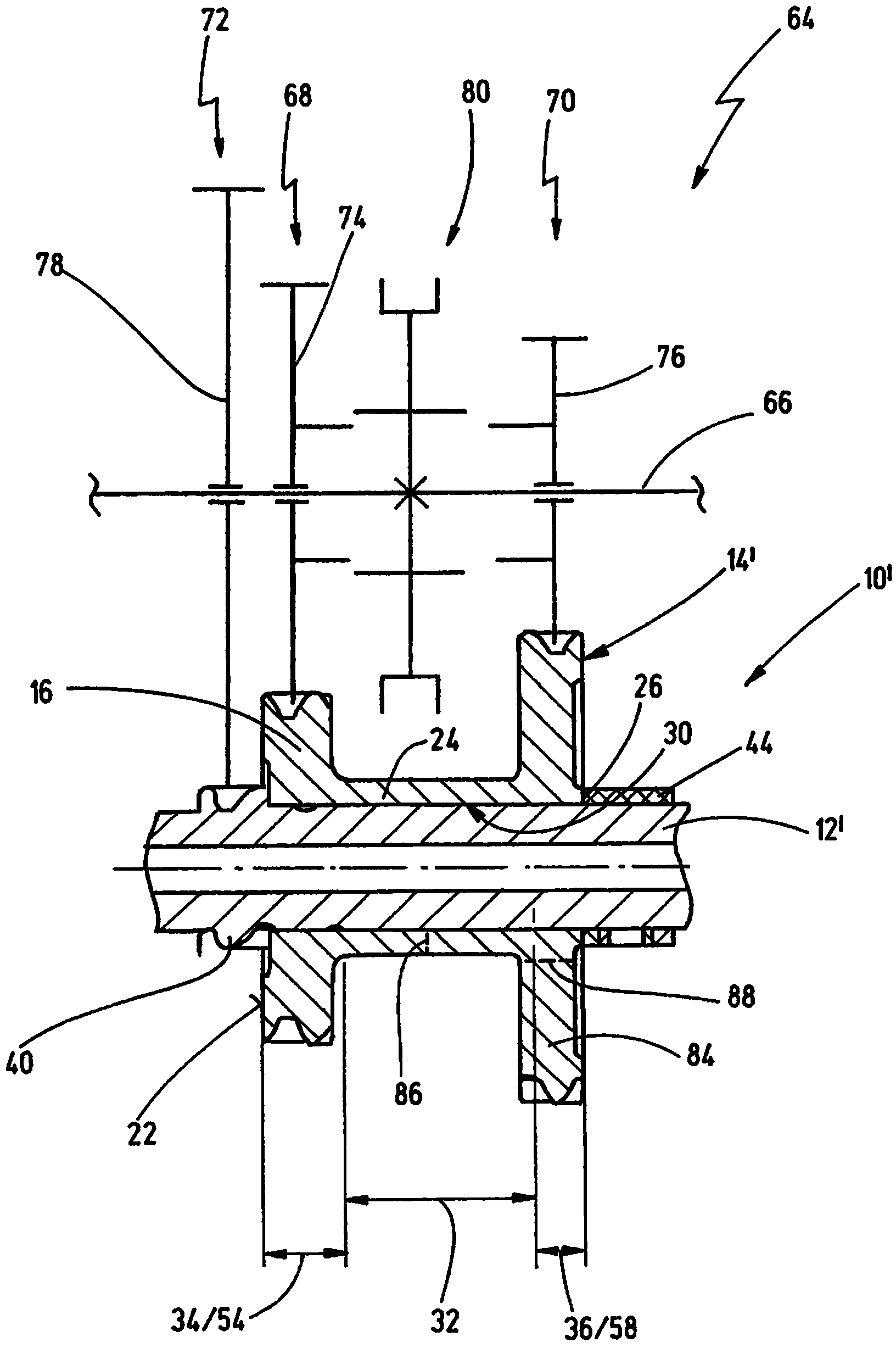

[0055] exist figure 1 , a first embodiment of the shaft arrangement is shown schematically in longitudinal section and is indicated generally by the reference numeral 10 .

[0056] The shaft arrangement 10 has a shaft 12 which may be a solid shaft or a hollow shaft. The shaft arrangement 10 also includes a fixed gear arrangement 14 .

[0057] The fixed gear arrangement 14 has a first fixed gear 16 which has a first fixed gear tooth system 18 on the outer circumference. The first fixed gear wheel 16 also has a first axial side 20 and a second axial side 22 .

[0058] The fixed gear arrangement 14 also comprises a hollow shaft section 24 which extends in the axial direction from the first axial side 20 of the first fixed gear 16 . Preferably, the axial length of the hollow shaft section 24 is at least as long as the axial length of the first fixed gear wheel 16 and preferably less than four times the axial length of the fixed gear wheel 16 . A hollow shaft end of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com