Diamond impregnated wire line coring geological bit and manufacturing method thereof

A diamond-impregnated and wireline coring technology, which is applied to drill bits, drilling equipment, and earthwork drilling and mining, can solve problems such as hole inclination, poor drill bit gauging and centering, and unfavorable drilling centering and guidance. Spectrum performance, improve the effect of internal and external gage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In the following, the present invention will be further described in conjunction with the drawings and specific embodiments.

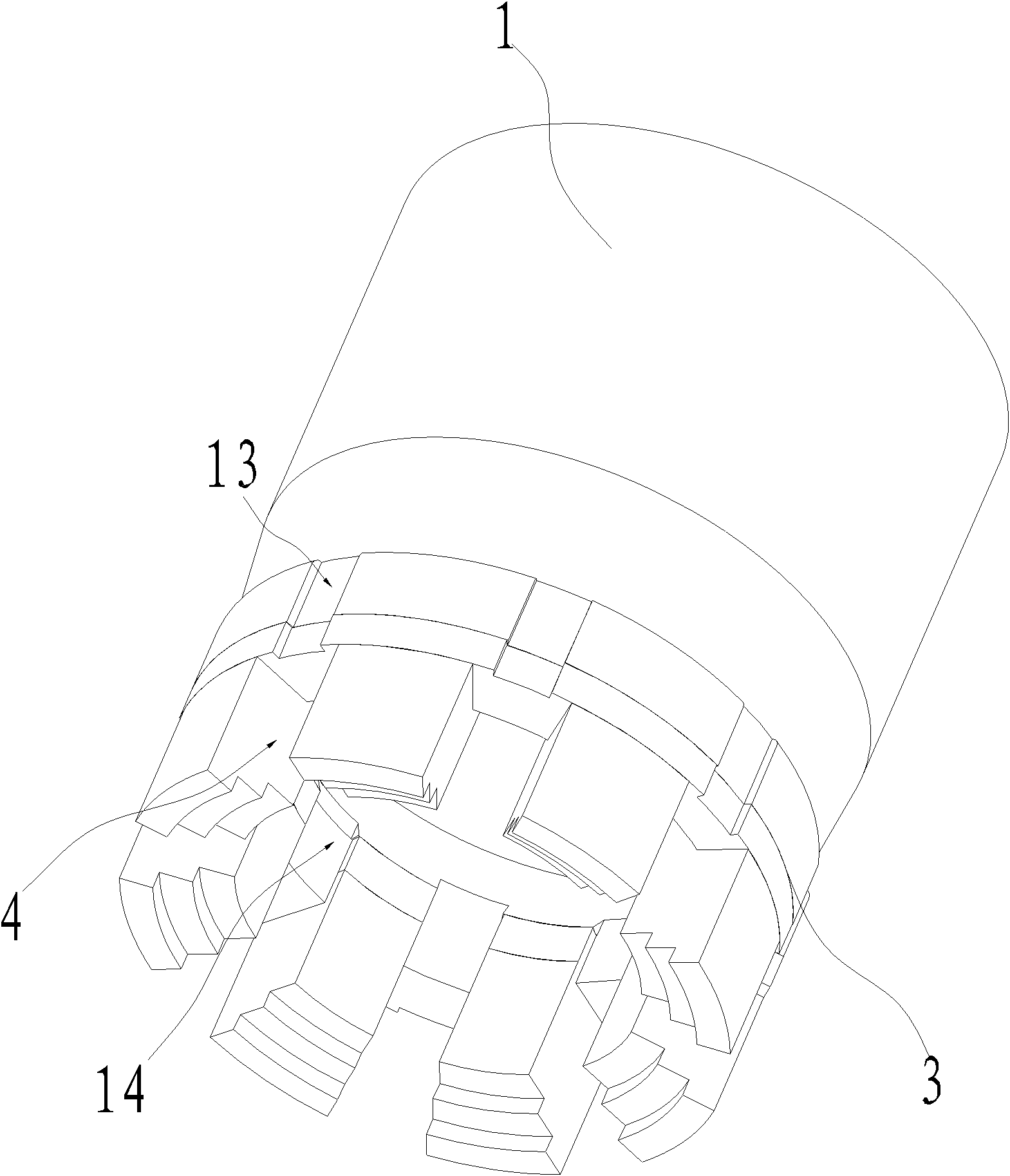

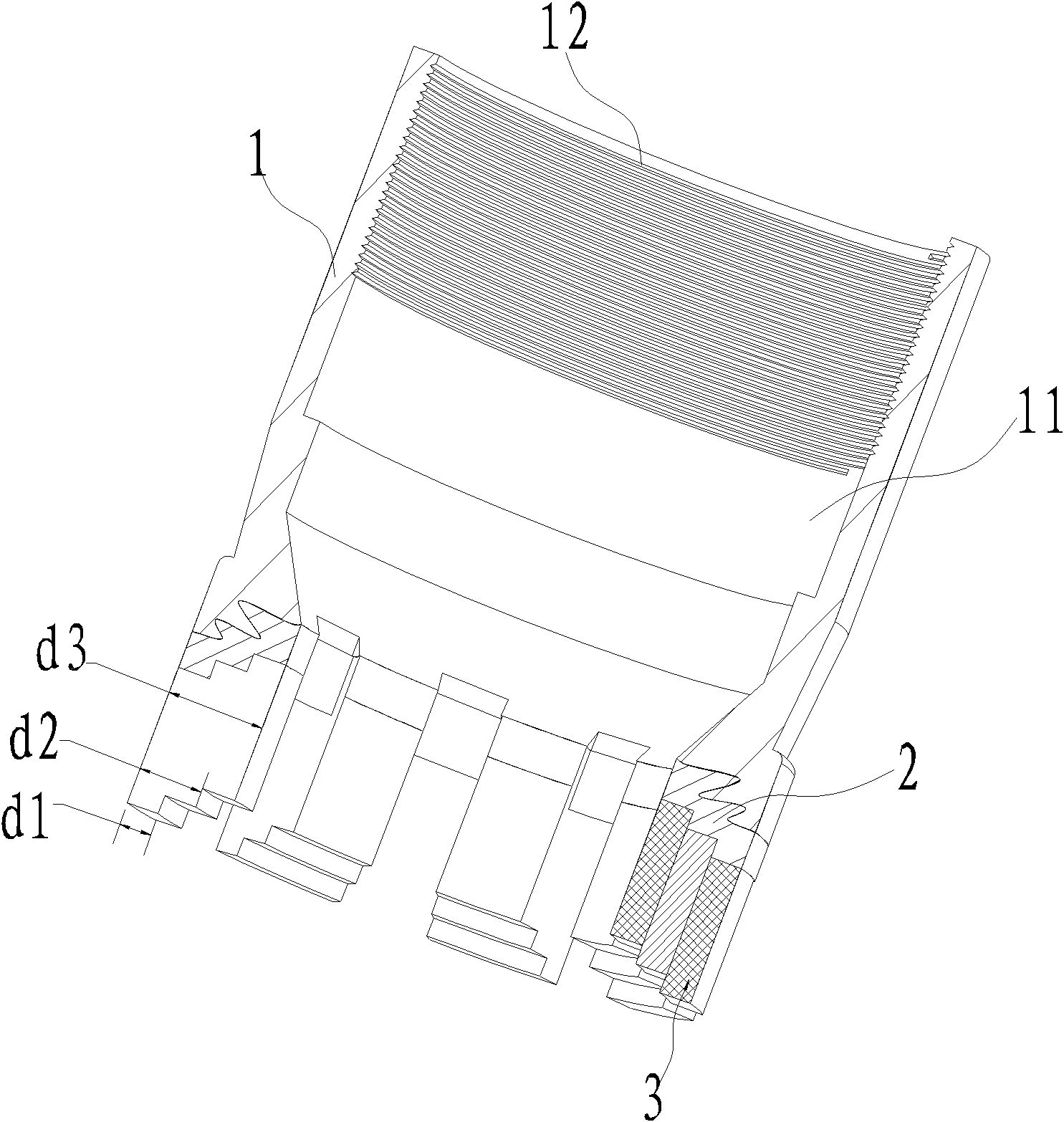

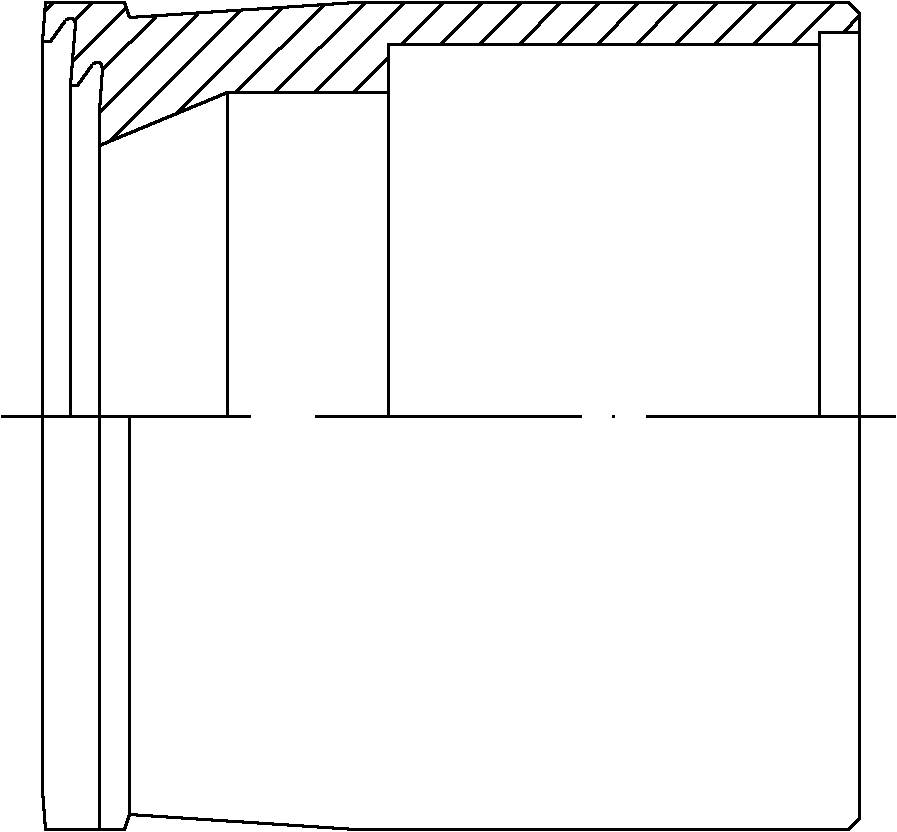

[0060] Such as figure 1 , 2 , shown in 3, is a kind of diamond-impregnated rope coring geological drill bit of the present invention, comprises drill bit steel body 1, cutter head 3, and is used to connect the connection layer 2 of drill bit steel body 1 and cutter head 3, wherein, drill bit The steel body 1 is in the shape of a cylinder, and a recess is provided on its lower end surface. The recess is in the shape of a dovetail step on the axial section of the drill bit steel body 1. The cutter head 3 is docked with the drill bit steel body 1 and has a dovetail step shape. The end part is connected with the drill bit steel body 1 through the connecting layer 2, specifically, a sintering process can be adopted. Due to the use of the dovetail step-type connection recess, the contact area between the connection layer 2 and the drill bit steel bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com