New type grouting device with fixed point control area

A grouting device, a new type of technology, applied in shaft equipment, wellbore lining, mining equipment, etc., can solve the problem of inability to realize strengthened grouting in fixed-point areas, increased frequency of drill hole collapse accidents, and inability to reuse drill holes and steel pipes and other problems, to achieve the effect of shortening the construction period, improving the effect of grouting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

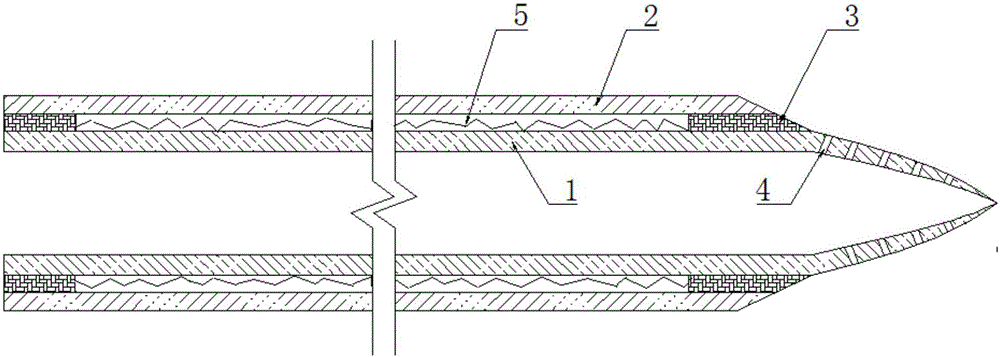

[0015] A new type of grouting device with fixed-point control area, such as figure 1 As shown, it includes: an auxiliary pipe 2, a grouting pipe 1 and a grouting hole 4 arranged on the grouting pipe 1, the grouting hole 4 is circular, oval, square or rectangular, and the grouting pipe 1 One end is conical, the grouting pipe 1 is directly inserted into the auxiliary pipe 2, the grouting pipe 1 is inside the auxiliary pipe 2 except for the conical end, and the gradient between the end of the auxiliary pipe 2 and the horizontal plane is 15° °~30°.

[0016] The inner diameter of the auxiliary pipe 2 is larger than the outer diameter of the grouting pipe 1 .

[0017] The gap between the end of the auxiliary pipe 2 and the grouting pipe 1 is filled with sealant, and the rest of the gap is filled with butter or Vaseline lubricant 5 .

[0018] The gap betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com