Fixed-point controlled area hole bottom mixed double-fluid grouting pipe

A dual-liquid grouting and grouting pipe technology, which is used in vertical shaft equipment, wellbore lining, mining equipment, etc. Can not be reused and other problems, to achieve the effect of shortening the construction period, improving the grouting effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

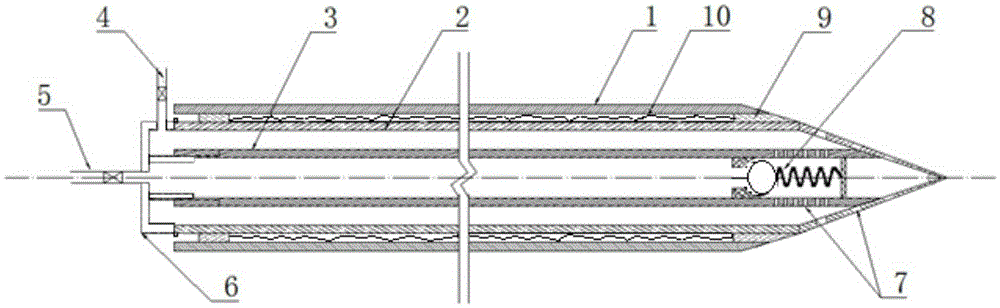

[0018] A mixed double-fluid grouting pipe at the bottom of a fixed-point controlled area, such as figure 1 As shown, it includes: auxiliary pipe 1, grouting pipe outer pipe 2, grouting pipe inner pipe 3 and the grouting hole 7 arranged on the grouting pipe outer pipe 2 and the grouting pipe inner pipe 3, and the inner diameter of the auxiliary pipe 1 is larger than The outer diameter of the grouting pipe outer pipe 2, the outer diameter of the grouting pipe outer pipe 2 is all in the auxiliary pipe 1 except the conical end, the inner diameter of the grouting pipe outer pipe 2 is greater than the outer diameter of the grouting pipe inner pipe 3, the The end of the inner pipe 3 of the grouting pipe is installed with a check ball valve 8 to prevent the slurry from flowing back. The slope between the end of the auxiliary pipe 1 and the horizontal plane is 15° to 30°. There are connection terminals 6 .

[0019] The auxiliary pipe 1 is a non-metallic pipe.

[0020] Preferably, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com