Laser shield tunneling machine and tunneling method

A technology of shield machine and laser, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of single and incomplete experimental performance, and achieve the effects of reducing wear, improving efficiency, and improving tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

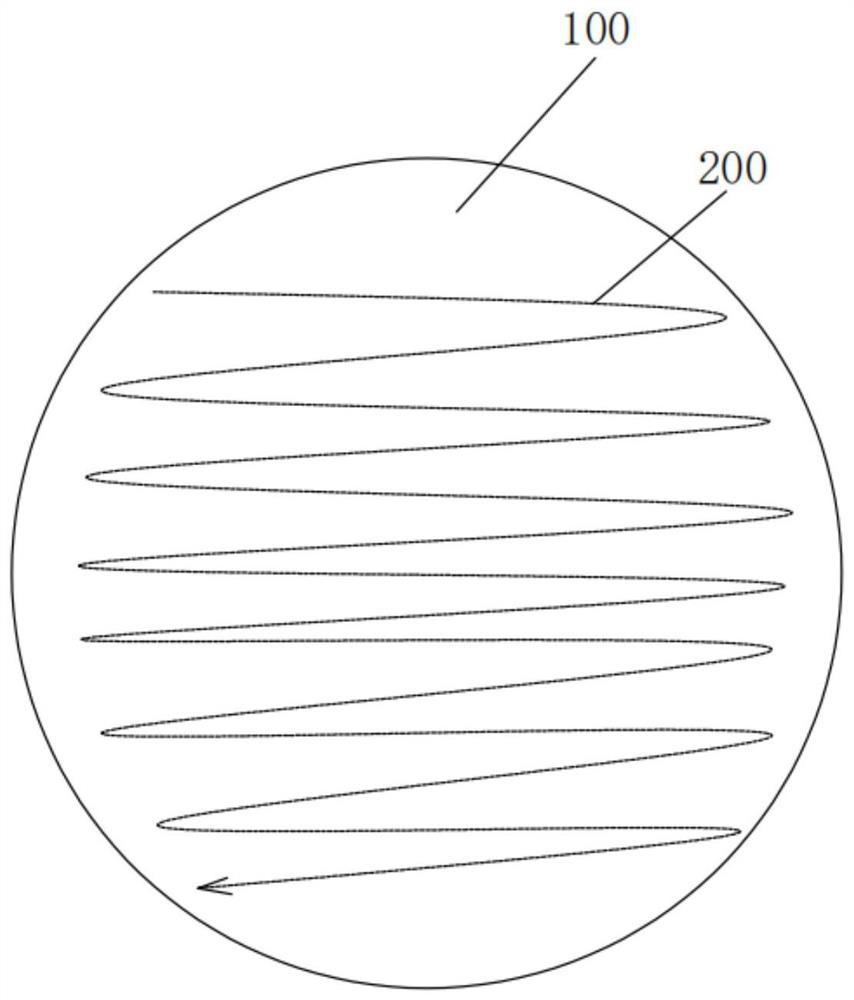

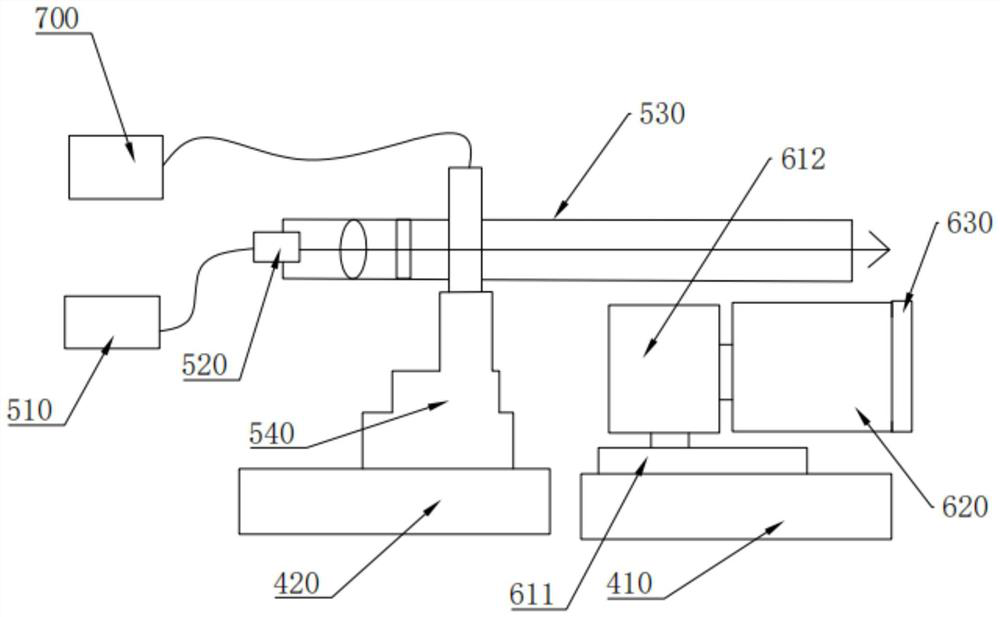

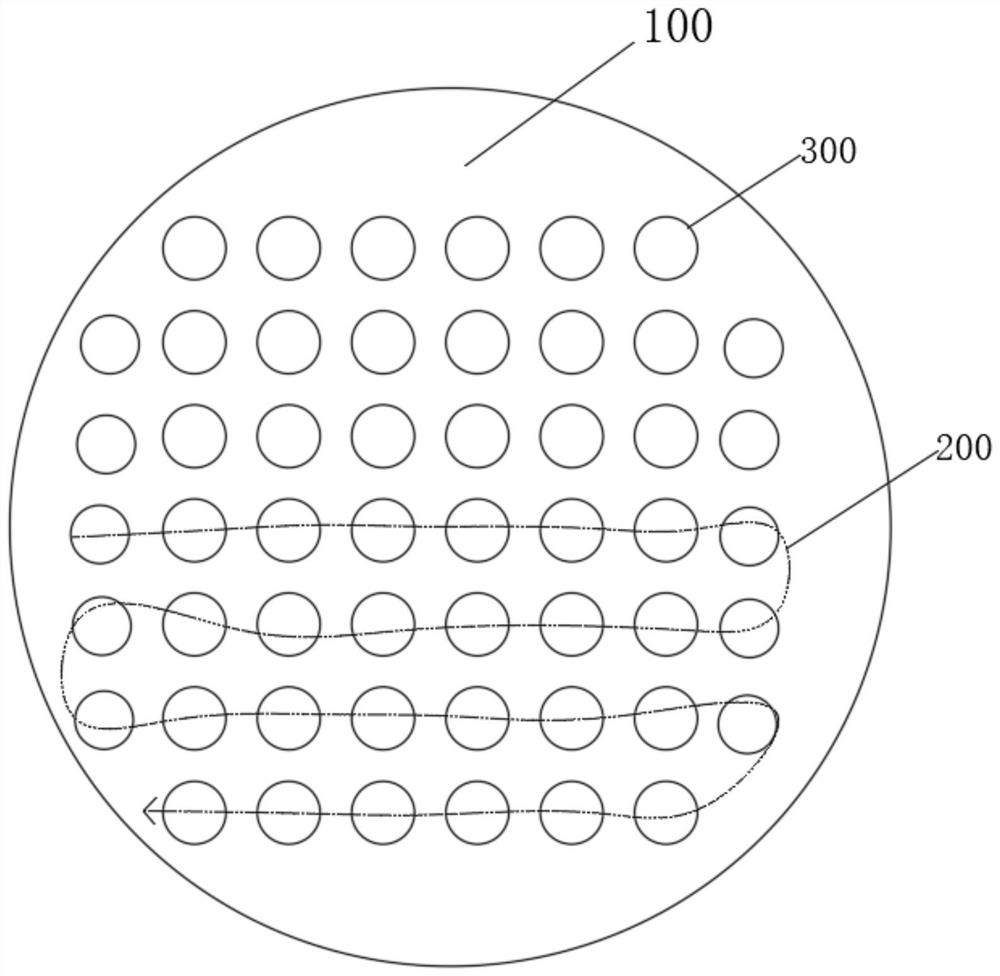

[0035] A laser shield machine, see Figure 1-2 , which includes a laser perforating device for perforating the working face 100, and a tunneling device for excavating the working face 100 after perforating by the laser perforating device. The laser perforating device and the tunneling device are of a separate structure.

[0036] Further, at least one laser perforating device is provided. The laser perforating device includes a laser 510, a laser output head 520, and a shooting barrel 530 connected to the output end of the laser output head 520 for protecting the laser channel. The laser 510 and the laser output head 520 pass through. The laser line is connected, and the optical axis of the laser beam output by the laser output head 520 coincides with the central axis of the shooting cylinder 530. The end of the shooting cylinder 530 is provided with a first laser hole for realizing the transmission of the laser beam to the working surface 100. A laser channel for laser beam tr...

specific Embodiment 2

[0051] The same places in this embodiment and specific embodiment 1 will not be repeated, and the differences are as follows:

[0052] Using multiple light sources and multiple shooting cylinders to perforate at the same time can be realized by two structures, specifically:

[0053] One is that one laser corresponds to multiple barrels, and the laser beam emitted by the laser is provided with a laser beam splitter. The laser beam splitter is a high-power laser beam splitter, which divides the laser into multiple beams. One-to-one correspondence of shooting cylinders to achieve the purpose of simultaneous perforation of multiple light sources and multiple shooting cylinders; the other is that multiple lasers correspond to multiple laser output heads and shooting cylinders, so as to realize the simultaneous perforation of multiple light sources corresponding to multiple shooting cylinders. Purpose.

[0054] Specifically, each shooting barrel is integrated into a whole, and the ...

specific Embodiment 3

[0056] The same places in this embodiment as in specific embodiment 1 and specific embodiment 2 will not be repeated, and the differences are as follows:

[0057] The laser perforating device and the tunneling device have an integrated structure. The shooting barrel 530 is integrated inside the rotating drum. A beam splitter connected to the laser output head is arranged in the shooting barrel 530. The beam splitter splits the laser output from the laser output head 520. For multiple beams, the first laser hole is provided with a plurality of laser beams, the drill bit 630 is provided with a second laser hole corresponding to each first laser hole, and the laser output head emits laser light through the first laser hole and the second laser hole. noodle.

[0058] Preferably, the second laser holes are evenly arranged on the upper surface of the drill bit.

[0059] A driving method using the above-mentioned laser shield machine is to pre-break the rock at the working face thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com