Oil and gas well staged fracturing drillable ball sliding sleeve

A ball-throwing sliding sleeve, oil and gas well technology, which is applied to earth-moving drilling, wellbore/well components, wellbore/well valve device, etc. , The effect of high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

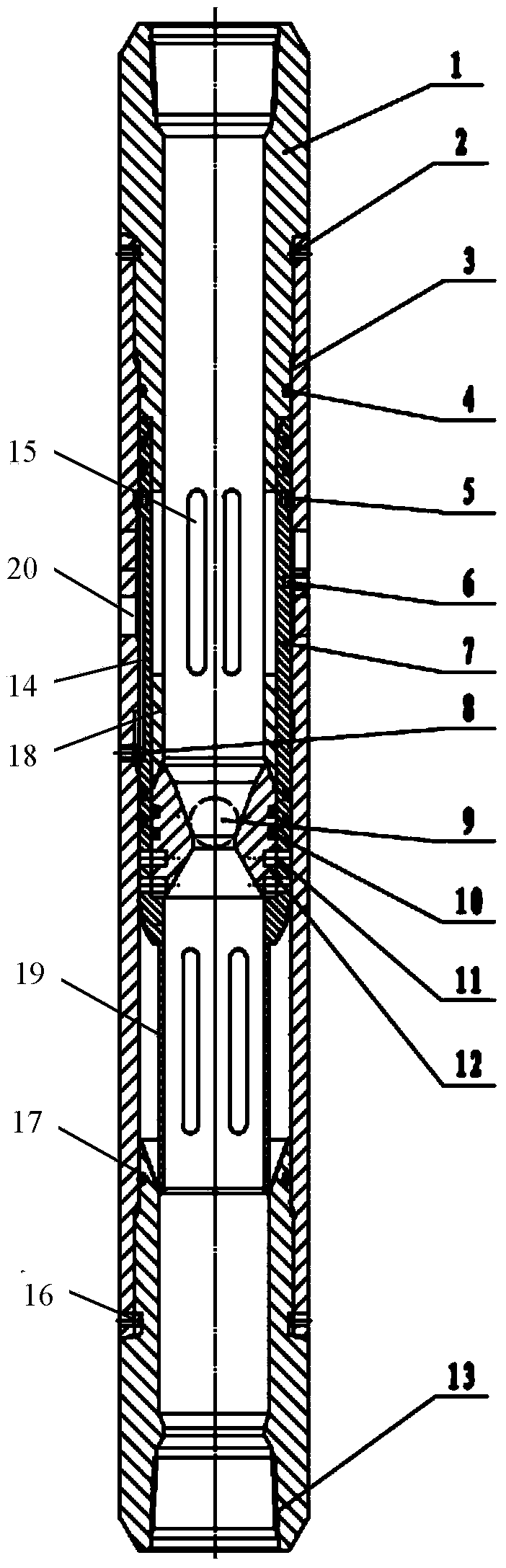

[0014] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] see figure 1 , the oil and gas well staged fracturing drillable pitching sleeve of the present invention includes: upper body 1, anti-return pin 2, middle body 3, seal 4, positioning circlip 5, shear pin 6, movable sleeve 7, guide pin 8. Low density ball 9, seal 10, anti-rotation pin 11, ball seat 12 and lower body 13. The upper body 1, the middle body 3 and the lower body 13 are sequentially connected by threads to form the main structure of the ball sliding sleeve, which can form a segmented string with the upper and lower oil casing threads and the completion oil casing. The upper body 1 and the middle body 3, and the middle body 3 and the lower body 13 are respectively provided with anti-retraction pins 2 and 16. A seal 4 is provided between the upper body 1 and the middle body 3 , and a seal 17 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com